IT’S the last day that the old fella will ever hear the familiar jangle of car keys in his trouser pocket. Recently, the people at the rego office said, sorry sir, you’ve failed. His licence won’t be renewed.

This article was first published in the September 2003 issue of Street Machine

He’s reflected on this, and decided that well, that’s it. It’s time to sell the Holden. He’s placed an advert in the paper during the week and now, looking at the car, is a young bloke who seems keen to buy the old Holden. He’s promised that it will be restored, not turned into some noisy hot rod.

Happy that his faithful car is going to a good home, the old fella reaches into his pocket and, for the last time in his life, hooks out his keys.

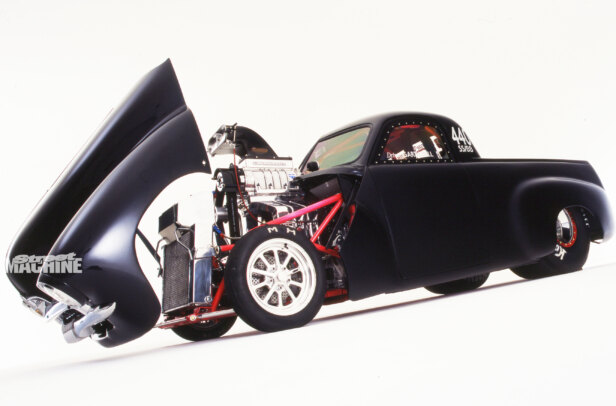

“It was a really good body,” says Armidale’s Jason ‘Dick’ Tracey of his purchase from the old fella. “We chopped the guts out of it. The whole floor was cut out in one section, starting at the windscreen and finishing at the back of the boot and sill to sill.”

So began the ‘restification’ of the FJ. It might not have been what the old fella had in mind, but as many will agree, it’s no good working with junk. Jason explains, “I was dragging them out of paddocks, but they were too far gone – you couldn’t do anything with them.”

Jason’s plans were tweaked a few times. “To start with, it was simply going to have a Hadfield chassis kit and a HR Holden ball-joint front end.” Input from the engineer saw the plans change – for the better.

“I couldn’t get the height I wanted with an HR front end,” recalls Jason. “Basically, I bought the car and contacted the engineer. I faxed through a list of things I wanted to do and he went through it: yes, no, yes, no, and what I had to have.

“The engineer didn’t want us to chop up a HR front end, so we got one made. We tacked everything in position at roughly the height we wanted it. We took it over to him (the engineer) and he went through it and told us to bring it back when it was finished.”

Most of the hard work was done on a rotisserie in Jason’s home shed. He points out that the car, with its totally new floor, firewall and chassis, was a team effort.

“The sheet metal fabrication, like the floor, went in and then Greg Yates in Uralla got it 90 per cent finished up to the priming stage,” he says. “Then we brought it back up to Cundy’s Smash here in Armidale to finish it. The car was painted and trimmed in two weeks.

“We worked absolutely frantically – I didn’t go home before 12 any night – to get it done.”

One paragraph makes it sound quick and easy, but it was more than seven years before those two wild weeks. And it’s not finished yet.

“I’m still tidying up bits and pieces,” Jason says. “Actually, I’m building a house at the moment. I should have that done in a couple of months, then I’ll get back into the car.”

The front suspension is a stainless steel Ididit unit, employing Torana rack and pinion steering. This gives the low stance Jason wanted without any height/travel compromise. It’s mounted to the original FJ chassis rails, now boxed for strength, and spliced to the underbody. The firewall is recessed to allow the engine to sit back in the chassis. David Reddon performed much of the work.

Under the rear is a 9in diff swinging from a four-link rear sprung from Spax coil-overs. The rear brakes are Ford drums, the fronts HZ Holden calipers over Leyland P76 discs. The use of Leyland bits is a trick that tucks the wheels a few extra mill under the guards and gives a Ford stud pattern.

“I was going to stick a V6 in it, to be honest,” Jason says. “But then, well, there’s no substitute for horsepower! And I’ve always wanted an FJ

with a Chev in it!”

Armidale’s Greg Love built the engine. “I just told him I wanted it to go,” Jason remarks. “It’s not crazy or over the top. I gotta drive it on the street. Greg does a lot of stuff up here.” It’s a sensible combination of parts that should last forever under the B&M blower and billet air cleaner. The crank is Eagle, the pistons 7:1 SRP and the heads Dart IIs and it’s all fed from a BG-spec 780cfm Holley.

New flat floor with square rails, 9in underneath and still enough boot space for a family picnic

Behind it is a Powerglide two-speed auto. “It’s nothing special, just a manual shift kit and a big stally,” says Jason. “It sounds like it’ll do a million miles an hour!” The modified ’Glide was bought second-hand and freshened before installation. The big stally is a TCI 3000.

The colour is a standout. Unlike a high-impact colour such as some Ford and Holden paints of recent times, the mint green hue suits the Holden’s shape and is classic enough to look good forever. Jason’s coy about what it is but assures it’s an off-the-rack colour, not a custom brew.

“If you have to match a custom colour because of a crash or something, you can’t.”

The interior is based on a rare, factory option front bench seat. “It’s called a camper seat,” explains Jason. “It can be slid forward and the backrest lays right back so you can sleep on the three seat bits.”

Jason put his Bob the Builder skills to use by panelling the door trims and boot, before M&T McFarlane stretched some classy cow over the lot, incorporating the FJ’s original trim strips. The rear seat was built around the new wheel tubs and chassis. All glass, including the smooth front screen, is the responsibility of Greg Love – yeah, the engine builder – from Armidale Windscreens.

“It wasn’t an easy car to make look good,” reckons Jason. The Good Old Days weren’t as good as some will have us believe – especially with build quality.

“These 1950s Holdens – everything the factory put in them was rough. It was a pain in the arse, everywhere you looked.”

But the result is worth it. “I get some good comments and from all ages too,” Jason says. “It’s a pretty trick car, actually. It’s going to be a

regular once-a-week cruiser. I’d like to do a few shows. I’m not a trophy hunter but I’d like to see it do well for a year or so.

“There’s a lot of people who have put a lot of effort into this car and I want to give them the respect.” So far, from two shows (Armidale and Coffs Harbour) it’s been awarded more than a dozen trophies.

“One year, and that’s all,” Jason claims. “Then I’m chucking in the wife and kids and driving it!”

HUMPY HIGHLIGHTS

• Ididit double A-arm front suspension

• Gas struts on bonnet

• Camping seat/leather

• Cast alloy instrument surround

• Recessed firewall looks original

• Flat floor

• Master cylinder under floor

• Front and rear glass is hand-cut laminate

• Front glass is flush-mounted and butted

JASON ‘DICK’ TRACEY

1954 FJ HOLDEN SEDAN

Paint: Mint Green

DONK

Engine: 350 Chev

Heads: Dart IIs iron

Pistons: SRP

Crank: Eagle, stock stroke

Cam: Crane roller

Blower: B&M low-blo

Carb: BG Holley 780

Exhaust: CRS extractors

TRANSMISSION

Convertor: TC1 3000rpm

Gearbox: Powerglide

Tailshaft: Shortened; 4in thick-wall

Diff: 9in, narrowed on four-link

SUSPENSION

Brakes: HZ Holden alloy calipers and Leyland P76 discs (f), Ford drums (r)

BODY

Seats: Original fold-flat ‘camper’ front bench with fabricated rear

Trim: Leather by McFarlane

Steering wheel: Momo with alloy column by Andrew Gassbarri

Gauges: VDO Classic in Phoenix Foundry surround

ROLLING STOCK

Wheels: 15×6 and 15×10 Weld Pro Stars

Tyres: 185/60 (f) and 295/50 (r) 15s

THANKS

Tim Hewitt, Paul Merideth, Paul Davidson, Cundy, Greg Yates, Craig Saxby and all the other fellas who helped out by drinking beer on Saturdays

Comments