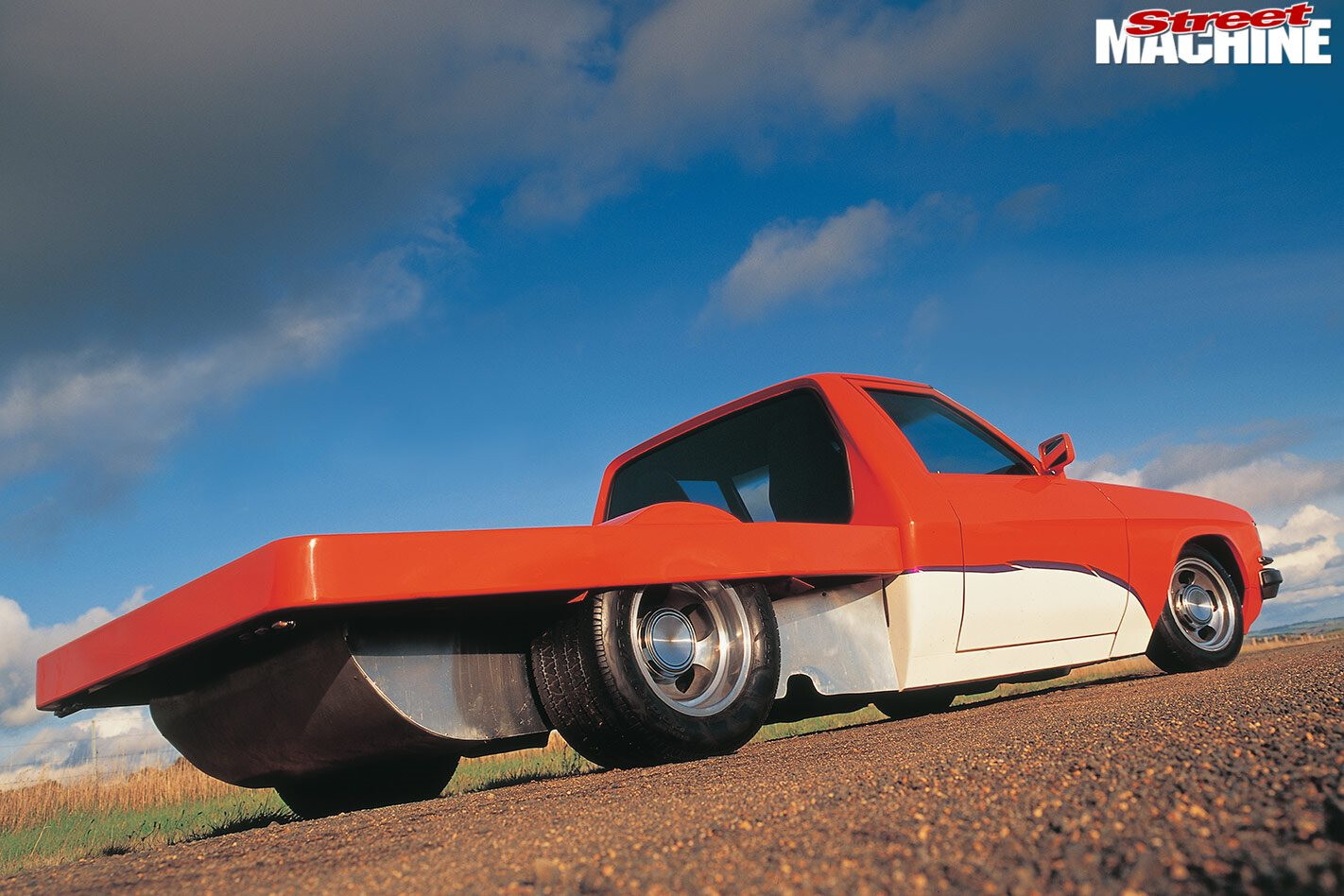

BUILT to the most demanding of timelines, this 1982 WB/HJ ute hybrid is a triumph of two mates’ persistence and dedication to the cause of making Summernats 14. But looking at the superb level of finish and engineering on the WB, you’d never guess this ‘gun at the head’ approach.

This article was first published in the March 2002 issue of Street Machine

The two players in this WB-against-the-clock game are Kev Grech (owner) and Joe Mifsud – a pair of hard-working Aussie blokes afflicted with a 10-year desire to make the Summernats. However, they didn’t make it easy for themselves, picking out an HJ one-ton rust pig as the basis for their ’Nats contender.

Resplendent in a shade of iron-oxide orange and missing a firewall it was probably more suited as a boat anchor, but they figured it was the spiritual home for the brand new 6/71 blower sitting in Kev’s shed. There really is a no more logical place for the big-lobed GM blower than on top of a pounding rat…and in Kev and Joe’s eyes the most righteous place for the force fed rat was always going to be in a ute, a Holden ute.

Kev, armed with a nibbler, some metal forming tools, and a welder, chewed out the rust from the tired tonner, replacing big chunks of floorpan and the complete firewall with off-the-shelf WB items. Getting the cab rust-free and fully sandblasted took only two days of solid yakka, and required some lifestyle changes to get the project completed. “With 100 days to go, it was bye, bye to sleep,” Kev says. A light-hearted remark, but an ominous sign of things to come.

In the end there wasn’t a whole lot of the external skin of the cab area worth keeping, with even the rear-window opening needing to be considerably relieved to get rid of the worst of the rust. In fact, so much had to be cut away that a custom rear windscreen was needed for the new enlarged hole. Blasting the chassis showed it was also well past its use by date, so rather than try to patch the ladder bars, Kev replaced it with a workable HJ unit from the wreckers.

With new doors and guards in place and the cab sitting atop the freshened chassis, the HJ was starting to look a complete unit, rather than a shemozzle of second-hand parts, for the first time in 30 days. And while Kev was massaging the bodywork, Joe had cut the axle tubes off an old 10 bolt and knocked together a tough nine-inch rear end. However, they realised they had taken way to long to get this far.

The pair had been tinkering away on the powerplant while the bodywork was coming together. It’s a fairly stout combination, too, with all of the internals specified and sized to cope with ‘reasonable’ amounts of boost from the 6/71. Forged pistons, able to withstand the higher cylinder pressures generated by the blower without going all crumbly around the ring lands, are the key for this type of engine.

With a blower poking through the bonnet, keeping the RTA happy was never going to be easy. Forget about conventional carburetion or fuel injection, too hard. The only way to keep the tailpipe sniffers happy, and not restrict the potential of the engine, was to use a twin Gas Research system and feed the engine on a diet of high-octane propane. Much to Kev and Joe’s surprise the ‘finished and tuned’ combination was signed off by the authorities with little hesitation.

The blower on this donk revs hard, even on LPG

Then it happened, the single action that could have derailed this project altogether. As the body was being prepped for paint, Kev had a suggestion.

“Hey, how about we drop the whole body four inches?” he said.

“No way, you mad bastard!” was Joe’s prompt response which did little to dampen Kev’s enthusiasm. By the time Joe arrived home from work, Kev had nibbled out the floor of the car, effectively setting the project back two weeks. There was nothing else to do but finish off the drop job, which, judging by the end result, wasn’t a bad idea at all – it was just the timing sucked.

Having said that, lowering the car four inches presented a whole set of new problems. The pedals didn’t fit and the wiring wouldn’t sit in its original spot – niggles you don’t need with just 30 days to go and three months worth of work left to do.

Kev’s little bro got involved at this stage, crafting the tray for the tonner as the rest of the ute was being painted. Blocking, two-pack and woodwork became a flurry of activity in the lads’ shed as they sucked the midnight oil harder than a top fueller. And there was still the trim to worry about…

With no time to muck about, they did a quick scour of the Trading Post and came up with a pair of pristine SAAS seats for the princely sum of $700. Once these were bolted in, a decent hood lining and set of door trims were whacked in leaving just the problem of preventing bugs smashing in their faces during a cruise. Thankfully Joe’s better half works for Windscreens O’Brien, so they were able to get some windows cut and slammed in in no time.

Moment of truth was Christmas Day. “We turned the key and Wubba!” Kev says, the gods smiling on their engine-building efforts and giving them nine days to tune up the big beastie with the help of Mike at Glenlyon Motors.

After a final polish, Kev and Joe were ready with their first Summernats entry and cruised down feeling justifiably proud of a monumental achievement. Some may have waited an extra year for their first foray into ’Nats show biz, but these first time entrants did the job in 100 days and were still mates at the end.

KEVIN GRECH & JOE MIFSUD

1982 WB HOLDEN UTE

Colour: Motorspray Bright Orange

MAKIN’ IT MOVE

Type: 454 big block

Rods: Stock, prepped

Heads: Square port, cast iron

Carb: Gas Research 510 x 2

Blower: 6/71

HIDIN’ UNDERNEATH

Gearbox: Turbo 400

Converter: 2000rpm stall

Diff: Nine-inch, 3.90 gears

Brakes: Stock one tonner

IN THE PLEASURE DOME

Seats: SAAS

Steering wheel: Momo

ROLLIN’ STOCK

Rims: 14×7 and 15×10 Jelly Beans

Rubber: 205/50/14 and 305/50/14 BF Goodrich

Comments