Drag Challenge regular Andrew Natoli’s plastic-powered VK Commodore has always punched above its weight, reliably running into the 10s with a basic aspirated 320ci Holden combo that made a healthy 540hp with an offset-ground factory crankshaft.

This article was first published in the August 2020 issue of Street Machine

But when you count the lads at BG Engines among your mates, the temptation to step things up is ever-present.

“I wanted to build Andrew a nice little LS for the VK, but I couldn’t get him interested in the idea – never late in a 308, he reckons!” grins Damian Baker from BG.

So the new engine had to be Holden-based and make plenty of grunt, but it had to do it on a budget, and that’s not easy to achieve. But BG Engines has been mucking around with Holdens for years – co-owner Mick even won a national title in a plastic-powered C dragster – so they drew on that experience to spec a combo that would make the numbers without breaking the bank.

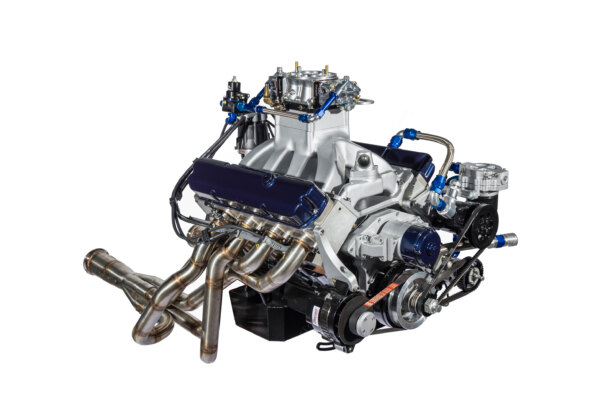

A VT block was sourced and prepped, with the usual oiling mods performed to ensure sufficient volume and pressure in the right places at high rpm. Notably though, the engine forgoes the usual bronzed lifter bores and four-bolt mains caps, with Damian instead opting for one of BG’s own mains stud girdles.

The rotating assembly consists of a Scat steel crank, Eagle rods and RaceTec custom pistons, with a lofty 13:1 compression ratio. Despite this, the engine will happily run on premium unleaded on the road legs of Drag Challenge, while Andrew will switch to VP109 at the track.

Heads are Edelbrock alloy castings, ported in-house and fitted with larger inlet valves. The valvetrain has been specced with longevity and reliability in mind – essentials for an engine aimed at Drag Challenge. Through extensive R&D gained on Al Vella’s all-conquering all-motor Capri, Damian has learnt that roller lifters are prone to failure in extreme operating conditions. For that reason, he’s opted for a flat-tappet camshaft in Andrew’s engine, but with high-ratio 1.8:1 Crower roller rockers to maximise the available valve lift given the relatively modest cam profile.

“It’s a bit of a NASCAR-type strategy,” Damo says. “It’s a smallish camshaft, which takes the heat off the rocker, but we still end up with a heap of valve lift. We’ve gone to an LS-style valve spring that is lighter than a Holden spring, which places less pressure on the flat-tappet lifters. The lifters themselves are cool-faced, with a 12thou hole in them to lubricate the lobes. It’s all about longevity.”

The net result is 261/268 duration at .050in lift on 110-degree centres, and a total of .720in valve lift – pretty hefty for a flat-tappet arrangement. “It’s basically the greediest-grind camshaft we could get for an 842 lifter,” Damian says. “It performs really well but is a lot cheaper to put together, and it should be far more reliable and less maintenance-intensive than a full-effort combo like Al’s engine. Being greedy and chasing the ultimate timeslip with an aspirated combo is great, but it’s hard work! Here we’ve optimised some things and backed off in other areas to ensure longevity and reliability.”

Crowning the mill is a hand-ported Harrop single-plane intake manifold topped with an 850cfm carb. Damo tested a 950 on the dyno, but it didn’t improve performance, so they reverted to the smaller carb in the interest of driveability. Another thing they tested on the dyno was nitrous! A basic wet-plate kit yielded a massive 922hp and 700ft-lb at 7000rpm on the engine dyno on VP109 – monstrous figures for a two-bolt, flat-tappet Holden V8. Even aspirated it performed brilliantly – 690hp on VP109 and 670hp on pump unleaded.

“Andrew’s made some improvements to the car and it will run comfortably into the nines on the motor,” says Damo. “We’re hoping it’ll land in the high eights with the bottle hooked up. It’ll be a fun little thing!”

CLASS WAR

A NITROUS combo gives Andrew the option of debuting the new engine in the aspirated classes at DC and progressing to the blown classes should he decide to go that way. The team has identified that Turbosmart Outlaw Blown isn’t a heavily populated class, so with the spray hooked up and slicks bolted to the VK, there might be an opportunity to shake things up a little!

Comments