IT’S tough at the top. Gone are the days when you could rock up to Summernats with a cleaner-than-average streeter and waltz into the Top 60. The standard has gone through the roof yet competition is fiercer than ever — if you make the Top 20, you really have created one of the best cars in the country.

This article was first published in the June 2011 issue of Street Machine

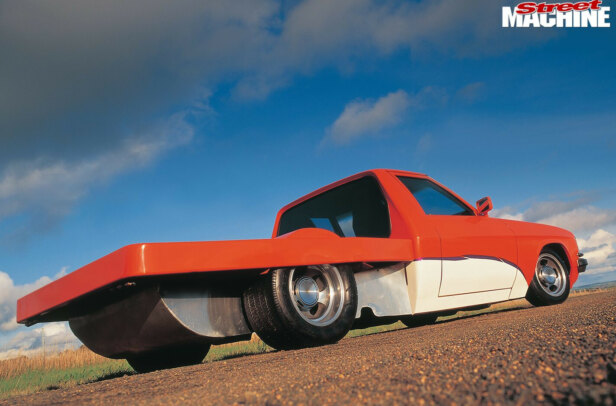

Speaking of the country, that’s where truckie Aaron Willis built his WB ute; at his home in rural NSW. He approached the project with a modest budget, plenty of enthusiasm and a willingness to get his hands dirty. His blood, sweat and tears were poured into the stunning hay-hauler, so you can imagine how stoked he was when it drove into the Elite Hall, then won a Top 20 plate and Top Ute. Not bad for his maiden show car build.

The hidden tailgate hinges really clean up the back end, while the tray was tidied up with smoothed seams and spot welds

“I would’ve been happy with Top 60,” he says, “so Top 20 was a huge reward after all that hard work.”

Summernats 24 was the end of a journey that began 12 years ago, when Aaron bought the ute to replace a VL Commodore lemon. Sporting a 253, four-speed and power steering, it was a faithful hack for two years until he decided to drop in a 308 and T350. He also treated it to a backyard respray in “a horrible pinky colour” but when the rego lapsed, it sat in the shed while he stockpiled genuine Holden parts for a ground-up rebuild.

Brilliant presentation, with polished everything as well as smoothed and detailed inner guards and firewall. EFI-equipped injector hat provides a tough look without compromising reliability and drivability

When he eventually got stuck into the shell, he did as much of the prep work as he could himself.

“I rubbed it back to the metal, sandblasted the chassis, plated and welded all the engine bay holes and removed all the spot welds. The car then went to a panel shop and they dicked me around.”

To escape the dicking around, Aaron went to Summernats, where he saw Andrew Ash from AA Panelcraft being interviewed. He liked what he heard and once he was back home, he gave AA a buzz.

“Andrew had a look at the car and took on the job. I helped where I could, taking a week off work or going there on weekends because I had to keep costs down.”

He needed an engine that’d get noticed, so he enlisted Sam at Westend Performance to build a 400ci Chev with a Blower Shop 8/71, 210cc AFR alloy heads, SRP forged blower pistons, Scat crank and rods, and a custom roller cam. But it’s the EFI that he likes best.

“It runs a Haltech 1000 ECU and 1000cc injectors plumbed into the top of the hat because I wanted that methanol look. It made about 800hp on pump fuel, it starts just like a normal car and it’s reliable. I thought about a methanol motor but Sam said they can be temperamental and high maintenance, so when E85 becomes more available we’ll run it on that. Apparently on E85 the hat will ice up and everything!”

Cogs are handled by a Turbo 350 auto with a 3500rpm TCI converter, and the nine-inch runs a Strange nodular centre, full spool, 31-spline axles and 3.7:1 gears. Like the rest of the undercarriage, it’s finished in HOK Black Cherry. Other components, including the twin three-inch exhaust, are polished to a brilliant sheen. Again, it was Aaron who put in the hard yakka.

“I had a polisher muck me around so I learnt to do it myself. I got quoted $2500 to polish the exhaust; I did it for $250, including buying the equipment, but it took 100 hours. I did all the stainless bolts and stuff, but Moulding Repairs & Polishing did the external mouldings.”

As the car was coming together, Aaron asked Andrew about a Summernats unveiling. Andrew spoke to Owen Webb, who then kept an eye on the build. But just before the paint went on, an important decision had to be made.

The underside of the floorpan was coated in satin Black Cherry; items such as the diff and leaf springs are gloss. Aaron spent more than 100 hours polishing the exhaust system

“Andrew suggested that we use a satin finish underneath and in the engine bay to break it up and make the motor and the polished stuff stand out. I wasn’t sure and it wasn’t until the dying hours that I decided to go with it, but I’m happy that I did.”

The final piece of the puzzle was the trim, and Mick’s Custom Interiors did a sensational job.

The beautifully sculpted fibreglass rear firewall in the cabin that moulds around the seats is a real highlight, as is the custom centre console which integrates nicely with the B&M Magnum Grip shifter

“I wanted flat floors and the fibreglass backboard behind the seats and Mick came up with some great ideas, like the completely custom seats and centre console,” Aaron says. Everything’s wrapped in honeycomb leather and suede, which contrasts beautifully with the dark paint, while a stack of billet accessories accent it nicely. Alloy inserts in the floors, door trims and dash are nice touches — expertly polished by Aaron, of course.

“It was challenging building the car in a rural area. There was a lot of travelling because the motor, gearbox and interior were done in Sydney and the diff was built in Canberra. It was hard finding time to pick stuff up. I got onto a heap of brand new genuine panels and drove to Melbourne and back in a day to get them!”

Still, that persistence, plus long hours and adherence to the budget paid off. Aaron plans to show the car for 12 months, including another crack at Summernats, before enjoying some time behind the wheel.

“It’ll stay a show car — I won’t thrash it too hard!” he claims. With an 800hp, 8/71-blown 400 Chev at his disposal, the temptation might be hard to resist.

AARON WILLIS

HOLDEN WB UTE

Colour: HOK Black Cherry

ENGINE

Brand: Chev 400ci

Induction: Blower Shop 8/71

Heads: AFR 210cc alloy

Camshaft: Custom roller

Conrods: Scat H-beam

Pistons: SRP forged

Crank: Scat 4340 forged

Oil pump: Melling

Sump: Melling

Preferred fuel: E85

Fuel system: Bosch 044 pump

Cooling: Aussie Desert Cooler alloy radiator, twin 14in thermos

Exhaust: Custom 4-into-1 headers, twin 3in system

Ignition: MSD

TRANSMISSION

Gearbox: Turbo 350, fully manualised

Converter: TCI 3500rpm

Diff: Nine-inch, Strange nodular centre, 3.1:1 gears, full spool, 31-spline axles

SUSPENSION & BRAKES

Springs: King Springs coils (f) King Springs leaves (r)

Shocks: Monroe (f&r)

Brakes: DBA 330mm discs, twin-piston Commodore calipers (f), DBA 280mm discs, Commodore calipers (r)

INTERIOR

Seats: Custom

Wheel: Billet Specialties billet

Trim: Honeycomb leather & suede

Instruments: Auto Meter

Shifter: B&M Magnum Grip

Seatbelts: RCI harnesses

Stereo: Alpine

WHEELS & TYRES

Rims: Intro Matrix 19×8 (f), 19×10 (r)

Rubber: Falken 235/30/19 (f), 275/30/19 (r)

THANKS

My wife Cathy & kids Cody & Reagan; Sam at Westend Performance; ACT Diff Doctor; Mick’s Custom Interiors; Alan McCoy at Moulding Repairs & Polishing; Andrew at AA Panelcraft; Liverpool Exhaust; Chris at Showwheels; Shane at Electroplating Technology; Chris at Chromeworld; Chris at Ingrams Automotive Engineering; my mates Des, Rodney, Nathan, Michael & Brian

Comments