WHEELS can make or break a car. They’re often the first thing to be purchased for a car build, regardless of the design of the project. There they sit against the wall, with a huge dish that you can put your head into. They look sexy, but will they fit, and will they be in track? For a tough-looking ride, owners often want rear wheels with big outer offsets, but that usually means they’ll be illegally over-track.

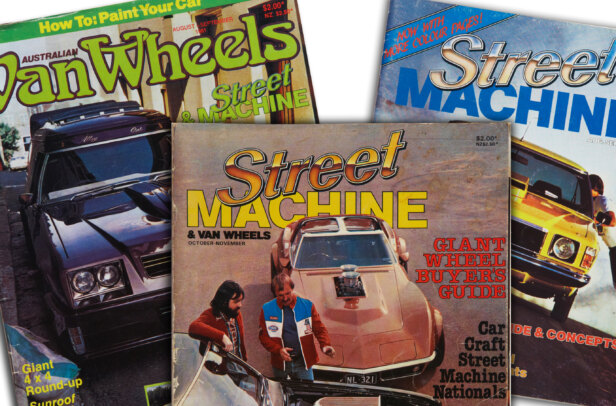

This article was first published in the April 2019 issue of Street Machine

So what exactly is wheel track? Track is measured from the centre of the tyre on one side of the car to the centre of the corresponding tyre on the opposite side. So when you bolt your chosen wheels onto your build, if the track varies by more than an inch from the factory track, you’re in trouble. The Department of Transport sets down a ‘one inch rule’, where wheel track must not be increased by more than 25mm beyond factory. The intent of limiting track variation is to minimise the risk of axle and bearing failure. As track increases with wheel offset, the bending moment on the axle also increases, as the wheel load is moved further away from the bearing.

It is possible in some jurisdictions to argue your case for larger tracks with the Department of Transport via an engineer, based on the lighter weight of the vehicle compared to that of the donor differential, or by the use of floating hubs, but this is by individual application.

So let’s have a look at what goes into choosing wheels and a diff that will give your project the desired look while still being within the rules.

CALCULATING DIFFERENTIAL WIDTH

So how do we work out that ideal diff width using science and logic instead of guesswork? The diagram on the right shows that by measuring your vehicle, you can work out your optimum diff width.

Start by measuring the inside width between your outer guards to get dimension ‘X’. This is not always easy; sometimes you may need to use spirit levels held vertically on the outer skin of the body, measure across the bootlid and then subtract the inner roll of the guard.

Next, measure the distance between your inner guards to get dimension ‘Y’. This can be measured under the car or by subtracting the two tub widths from dimension ‘X’.

Now it’s time to notionally put the width of your chosen wheel into the tub area. You must have clearance (dimension ‘C’) between your wheel and the inner and outer guards. This clearance is recommended to be 25-30mm or ‘two fingers’, to allow for lateral movement of the diff (and it does move) and bodyroll of the vehicle. Any less and the result is scrubbing, which will make for uncomfortable driving. For a front suspension, the pros allow a ‘C’ of 50-75mm, to allow wheels to still turn inside the guards if the car is sitting low.

Of course, if your wheel doesn’t fit within the guards, it’s either too wide or your tub is too narrow – so more decisions!

Now choose a backspace for your wheel that will give you the look you want while still meeting the track rules we mentioned earlier. This is dimension ‘B’. Keep in mind though that wheel-makers measure backspace to the outside of the wheel, but tyre-makers measure to the internal tyre shoulder. So a 10-inch wheel will actually be 11 inches wide outside to outside when the tyre is taken to account. That’s why we add 12.7mm (half an inch) per side when working out backspace.

If you have done this correctly, you can now work out the optimum width for the differential from wheel flange to wheel flange by using this formula: Y+(2xB)+(2xC).

Now you can order your wheels and your differential.

WHEEL OFFSET

FROM the diagram below, we can see that almost all production-car wheels have a positive offset. It’s the opposite of how we usually talk about positive and negative offsets, but it’s how wheel-makers talk. It means that there is more wheel on the inside of the flange than on the outside, and the distance from the true wheel centre line to the mounting face is outwards and ‘positive’. This philosophy has been used by the manufacturers since the beginning of time to place the centre line of the wheel over the axle bearing, transmitting the wheel loads to the bearing directly.

The biggest issue for modifiers is the process of choosing a differential. Some modifiers choose a diff that’s too narrow for their vehicle, so they have to push the wheels out to fill the guards and avoid inner guard scraping. This usually results in over-track and illegal wheels. You can put your head in the outside of these wheels!

Others choose a diff that’s too wide and find that they’re unhappy because they have to run flat-faced wheels to squeeze them under the guards. Not the way to build a stunning-looking street machine!

The answer to this problem is to plan the width of your diff. It’s 2019; you can order a differential to be made to whatever width you want. Or you can select from the myriad production-car diffs available.

WORKED EXAMPLE – FORMULA METHOD

ONCE you know the offset of the factory wheel belonging to your chosen diff, you can use the formula below to work out the backspace you need for any wheel width, and meet the track allowance too. Factory offsets are available in the Tyre & Rim Association Standards Manual or the Njoy Universal Tyre Fitment Guide. Of course, you could always just measure a factory wheel.

Using the most popular differential in modified vehicles, the Ford nine-inch, as an example, we know the best available factory wheel from Ford to give us the maximum track and the best wheel look has -1/4in (-6mm) positive offset. All other factory wheels were worse in the sense that they had bigger backspaces and therefore larger positive offsets.

This means that the legal wheel is a +6.7mm negative offset for a nine-inch diff, because when you add the two half-inch (12.7mm per side) increases, you get the inch over track. So the calculation is: Offset + half rim width + 12.7mm = Backspace.

Consider first our legal Ford factory offset on a 10-inch (250mm) wheel, where we know the offset is -6mm but don’t know the backspace: -6 + 127 + 12.7 = 133.7mm = standard backspace = 51/4in.

Now add 12.7mm (half an inch) to the wheel offset to increase track by one inch (2 x 1/2in) and we get : +6.7 + 127 + 12.7 = 146.4mm = max legal backspace = 53/4in.

AFTERMARKET WHEELS & THE ONE-INCH RULE

AS the fledgling Australian mag wheel industry grew in the 1970s, the government, in conjunction with the wheel-makers, made a decision to permit an over-track allowance of one inch (25mm) to give the wheel-makers some room to move with offsets. The arbitrary decision to allow an inch has stayed with us to this day, even though it has no basis in engineering.

The ‘one inch rule’ meant that the standard manufacturer’s track width could be exceeded by up to one inch when fitting aftermarket rims.

Traps For Beginners

THERE’S no need for trial-and-error when it comes to choosing wheels and suspension elements. Experienced modifiers choose the best available legal wheels first (using the method outlined in this article) and then calculate the optimal suspension widths to put those wheels where they belong. But for those new to the game, there are numerous way you can come unstuck:

- Not taking the time to understand wheel technology and how track works

- Using suspension components simply because you already have them and then having to buy wheels that are not optimal to fill in the space

- Measuring the width of independent suspensions without the wheels on the ground with load applied or the wheels aligned

- Forgetting about the bulge in the tyre and just using the wheel dimensions in calculations

- Not thinking about the roll in the guards and other forms and shapes inside the wheel tubs during calculations.

Comments