STAND close to Anthony Moore’s neat ’55 Chev and you’d swear you can hear a faint echo of Buddy Holly. It’s all bobby sox and 50s cool, sure enough.

But this is much more than a Saturday night drive-in special. Yup, there’s the neat yet subtle chop-top and the seriously fat rubber. But open the bonnet and any thoughts that this is just a pretty face are quickly erased. It’s more Steve McQueen than Fonzie.

This article was first published in the February 2011 issue of Street Machine

This is an 11-second drag car, raced by a bloke who’s spent the past 20 years making it go faster every time he drives it to — and sprints it down the quarter at — the drags.

Then again, taking Top Radical Custom honours at the 1999 Melbourne Hot Rod show is proof that the skin is deeply beautiful.

Anthony started into cool cars early. “My first car was an LH SL/R5000,” he says. “The Chev wasn’t my first build. I’ve done the Torana, an HZ Statesman Caprice and a 1965 Mustang coupe. I wrote the Statesman off and that’s when I found this Chev. I bought it from a guy called Billy Burnout who was in a rock ’n’ roll band in Cockatoo [Vic].”

With a 2.5in chop, the car has a tough stance. While the chop job was well done, finishing the rest of the build took a heap of patience and grunt from Anthony

That was way back in 1990, when he was a tender 23 years of age.

“It was stuffed. It needed two new doors, sill panels, new floor. It was pretty horrible, with a velvet interior, and the original Blue Flame six and three-speed column shift. Someone had welded patches over the steel and body-filled from there. You can imagine how ripply it looked.

“What attracted me was the fact it was chopped and that part had been done well. It wasn’t finished though; I had to do the doors, and all the moulds inside had to be chopped and cleaned up.”

The front glass was already in place, and the rear was Perspex. The side glass is laminated, cut from ‘ambulance glass’ available from windscreen outlets.

“They grind it down on a linisher. Most people just use the glass that’s there and don’t wind the windows up as high; mine is done properly. The biggest challenge was the quarter vents. The inside moulds were tricky — to line up the grooves was a nightmare, but we got there.”

The car was, and remains, a driver. Indeed, he can still fit the towbar that was on it at purchase.

“The first thing I did was hook up my ski boat and tow it to Albury. I used it almost every day for a year until the wishbone fell off. That was the thing that made me rebuild it.”

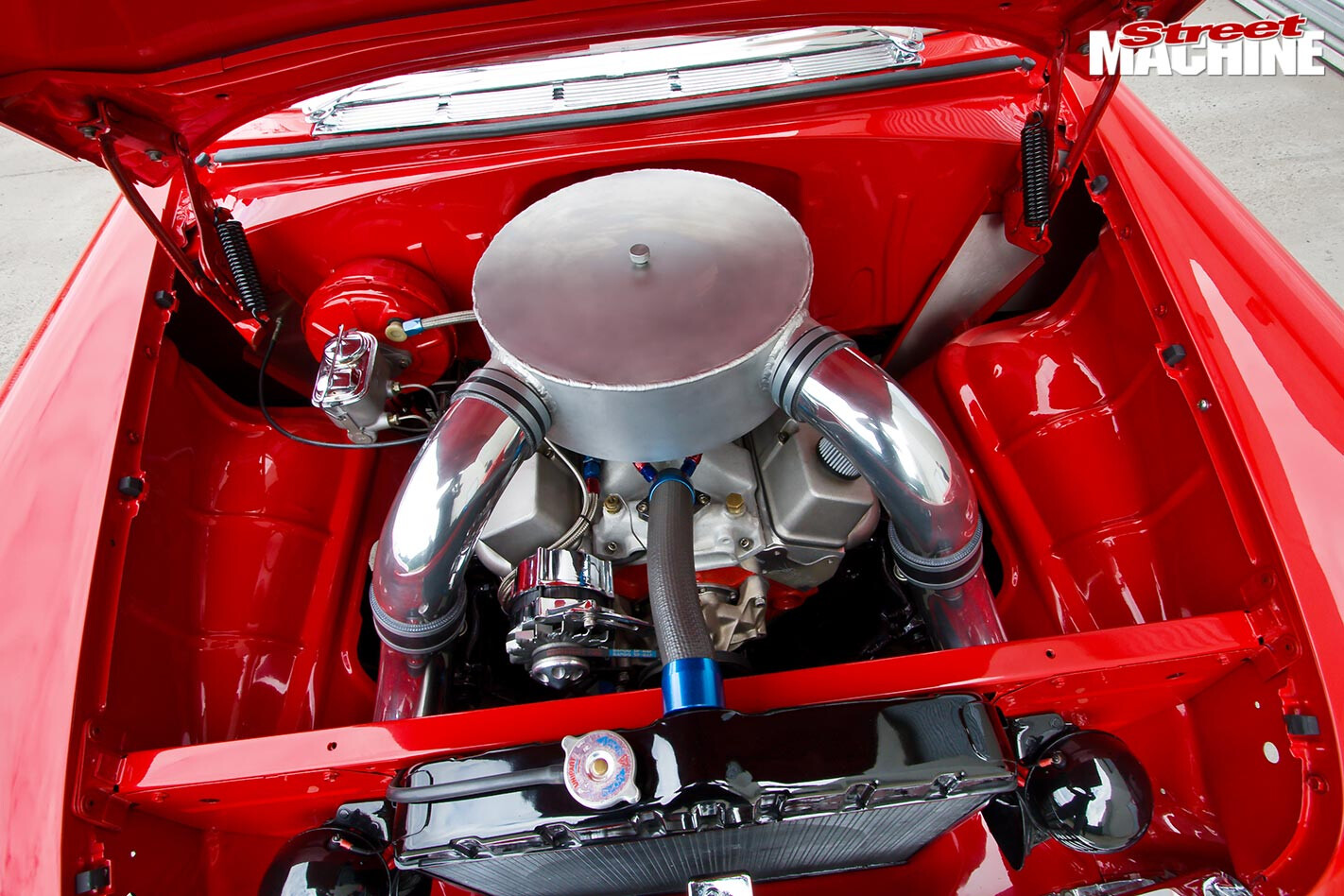

Air cleaner was hand-fabricated by Anthony. It gives an extra 3mph at the strip, supplying cold air and forced induction via hidden tubes that run through the radiator mounts

The first rebuild saw the old six replaced with a standard 283 donated from a mate’s ’57 Chev.

“It was rusty so I pulled it right down, cleaned it all up again and used that to run around for two years.”

Only after that did Anthony decide to take the car back to bare metal.

“Everything was wrong with the body. I repaired the inner sill panels and front floor; the firewall seams had to be welded up, the list goes on. It’s easier to say that everything had to be done and I did it myself.”

Pat Misiti interior is sweeter than when it popped out of the factory in ’55; that’s real leather you’re looking at. Glovebox-mounted CD player and gauges aren’t standard either

However, he reckons that the insides of the doglegs and the inner panels on the back doors were the biggest challenges.

“I had to fabricate all that and make it look original. I made the panels up, filled them with MIG weld, then ground it all back. Now, if you opened the door, you wouldn’t even know.”

To round out its first decade with Anthony, the car was treated to a new fuellie-headed 350 packing a small solid cam. Another 10 years on and a new alloy-headed 350 moved into the bay. The car ran 11.83@113mph in this guise.

Unfortunately, that donk threw a leg out of bed, which created the opportunity to fit the current 010 four-bolt 350, which is 30thou over and fully deburred. The 383ci engine was all-new, built with help from good mate Mario Vassallo (Trik HQ, SM, Dec ’85). Anthony says Mario’s attention to detail and planning helped make the ’55 the reliably fast car it is.

Cop this lot: the heads are AFR 195 single-’plug items, running 11.14:1 compression. An Edelbrock Victor Jr intake manifold is mated to a Holley 950hp Ultra carby. The cam is a Comp Cams Street Roller, with the grind decided by James Melmoth at Melway Race Engines. An Eagle 4340 crank and six-inch H-beam rods are coupled to SRP forged pistons, and the stroke is 3.750in. Drinking pump fuel, that lot made 539hp and 495ft-lb on the dyno.

You might think the temptation to go for a big-block would have been strong but Anthony reckons small is the way to go.

Anthony’s no fan of gauges on the column but reckons you need them when you’re running hard (left)

“Small-blocks make more power, simple as that. The technology and research going into small-blocks make them a much better choice. It’s big work to get big horsepower from a big-block. Too big.”

So far the car has made seven visits to Calder, with Anthony tweaking the set-up each time.

“It had a 3800 converter and ran 11.1@123mph. So I thought I’d put 1000 in the converter. I sent it off to TCE and we put a 4500 in it, which made it a lot better on the street, and made a lot more multiplication, but it’s not going quicker.”

Transmission is a Turbo 400. “A mate and I rebuilt it 10 years ago with Kevlar bands, race/street clutches and new thrust bearings. I wanted it reliable and when I put the new motor in it, we pulled it down after all those years and just put it back together. And it’s had a lot of thrashings.”

So what’s next in the pipeline for the Chev?

“I’m going to put a turbo 350 in it — that will make it quicker.”

Also going into the car is a Truetrac LSD running 4.3s and a nodular centre with a Daytona pinion support. The Truetrac is about making life easier.

“This way I won’t have to keep taking the diff out every couple of years to tighten the clutches up. The big wheels don’t ‘give’ so they give in the clutches.

“I’m chasing a 10.9, that would be great. But I’ve owned it this long and it’s not going anywhere so there’s no hurry.”

ANTHONY MOORE

1955 CHEVROLET 210 SEDAN

Colour: Spies Hecker red tint and white two-pack

ENGINE

Type: Chev 383

Induction: Holley 950HP Ultra

Camshaft: Comp Cams solid roller

Valve springs: Comp Cams

Lifters: Comp Cams solid roller

Pistons: SRP forged

Conrods: Eagle

Crank: Eagle 4340

Sump: High Energy

Cooling: Chev radiator, Mercedes Benz core, 16-inch thermo fan

Ignition: Holden distributor, MSD 6AL, 8mm leads

Dyno: 540hp@6500rpm, 495ft-lb

TRANSMISSION

Gearbox: T400 modified

Converter: TCE nine-inch 4500 stall

Diff: Nine-inch, Moser centre and axles, HD sprag, Raybestos clutches

Tailshaft: Three-inch, HD tube

SUSPENSION & BRAKES

Springs: Pedders heavy duty (f), modified leaf (r)

Shocks: Leslie 90/10 (f), HQ gas (r)

Steering: HK box, column & wheel

Rotors: VT discs (f), HQ drums (r)

Calipers: VT Commodore (f)

Master cylinder: HQ

ROLLING STOCK

Rims: Cragar Prostar 15×3.5 (f), Cragar Prostar 15×10 (r)

Rubber: Mickey Thompson ET Street radial 205/65 (f), 325/50 (r)

THANKS

Mario Vassallo; Ray Caruana, CE Transmissions; James Melmoth, Melway Race Engines; RC Nibbers Performance; Glen Goreman;

Gary Taylor

Comments