WHILE the six-cylinder Barra was Ford’s new-millennium high-performance engine of choice, the arrival of the Coyote quad-cam five-litre V8 in the Mustang a couple of years ago gave Blue Oval bent-eight fans a tough engine to take on the LS hordes. Ever thought about chucking one of these bad boys into your street machine? Well, Sydney’s RRS has developed a new Coyote swap kit to help you do it. We chatted to RRS’s Matthew Pankau to find out what’s involved in installing a Coyote into an XY Falcon.

This article was first published in the February 2020 issue of Street Machine

“These Coyote motors make huge power because they’re so much more efficient than an old pushrod motor,” Matthew explains. “You can’t get the same reliability, emissions or fuel economy out of an old motor compared to one of these modern V8s. The engineering in this motor is way better than what you could dream of in a street car engine. You can get more out of these just in tuning compared to an LS”

FITTING ROOM

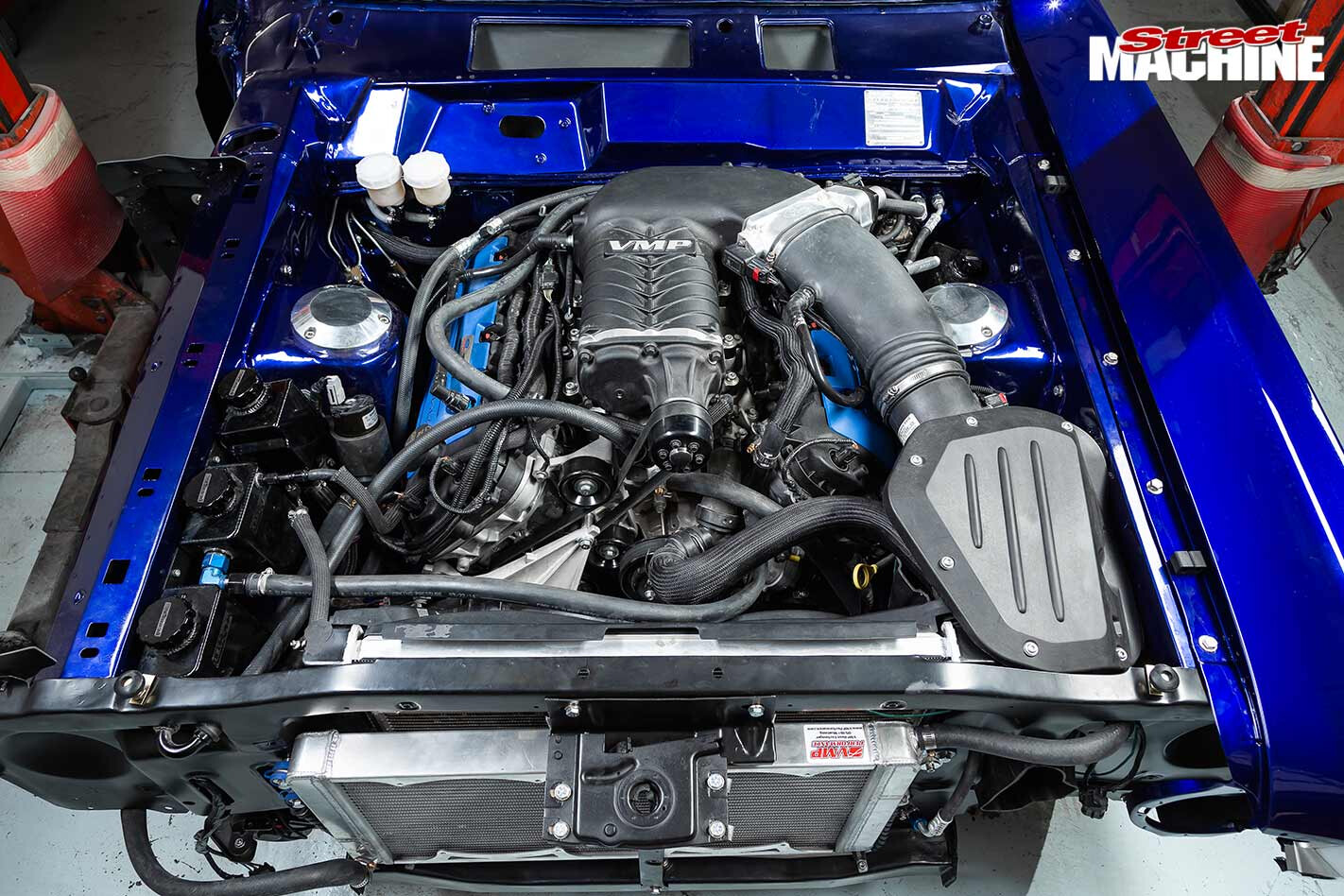

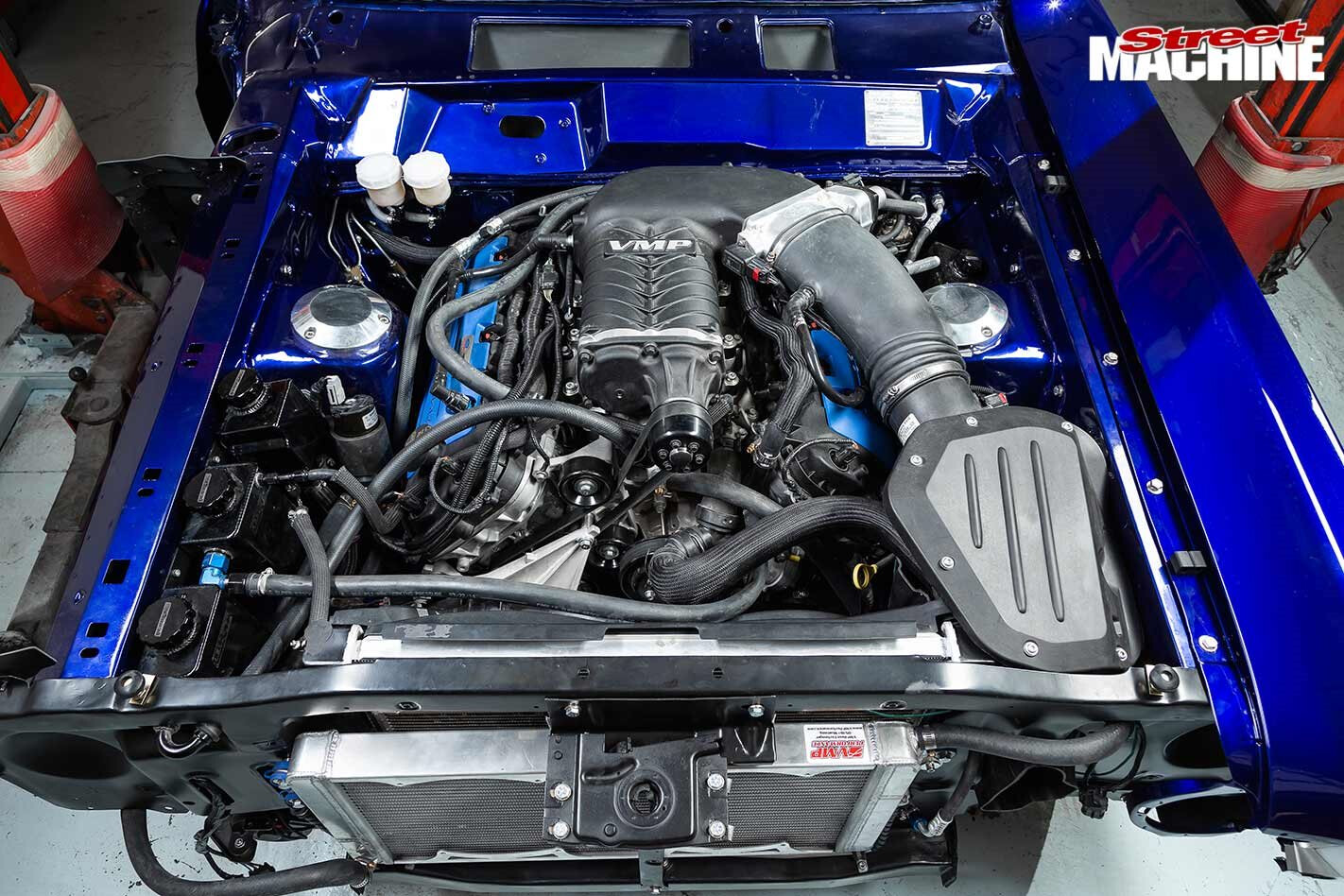

THE Coyote runs four cams and four valves per cylinder, so it’s a huge mill. Anyone who’s peered into a Falcon or Mustang engine bay knows there isn’t much real estate in there, so the stock shock towers will have to be notched to allow clearance for the exhaust and heads before the late-model five-oh can be installed.

RRS sells replacement pre-notched towers to go with the company’s strut front end used in this XY, and makes its own bolt-on engine mounts to suit both the Boss and Coyote blocks. For the oil pan, RRS uses an off-the-shelf Canton front-sump unit.

“The biggest challenge was making it all fit,” Matthew Pankau says. “The physical size of different components, like the back half of the transmission, was a huge hurdle. You need the right matched componentry all the way through, from intake system to tailshaft and wiring. You can’t use your traditional hot rodding with modern drivetrains; it is far more like science.

“You can make life much easier for yourself by buying a brand new 2017 Mustang floorpan for $1400, which means you can then use late-model seats and a centre-mount handbrake, and it reinforces the floor,” Matthew continues. “We can help walk a customer through the steps involved in building one of these cars, but each combination has to be tailor-made; this isn’t an Ikea kit. It is a lot more involved with the re-engineering.”

The engine in this XY is a hand-built Ford Racing item with upgraded internals, 11.8:1 compression, CNC-ported heads, special cams and more. Amazingly, with the RRS kit it bolts straight into the second-generation Falcon exactly the same as a stock Coyote. “It is just like a manufactured car, and is serviceable,” Matthew says

Matthew warns that some Coyote oil filter housings will foul on the XR-XY chassis. “We used a Ford Racing housing on the XY, though there are still clearance issues around the stock sway-bar brackets,” he says. “A 90-degree adapter is available to stick it out the front to fix this. The Ford Racing Coyotes come with an oil cooler, but that didn’t work in the Falcon chassis so we had to remove that. You can also remote-mount the filter if clearance is tight in your particular car.”

PIPING UP

THE result of 200 hours of development, RRS’s off-the-shelf, Jet-Hot-coated headers are suitable for Coyote swaps into both left- and right-hook Fords, including XK-XD Falcons, Mustangs and US Fairlanes. They’re designed to be fitted to the engine before it is dropped into the bay, so you don’t have to risk scratching your paint by threading your shiny pipes in from the bottom.

“The factory Coyote headers should be thrown in the bin, as they’re so restrictive,” Matthew says. “With the variable cam timing, these engines make so much power once you get rid of the stock headers, as they can finally breathe.”

With the RRS engine mounts and headers and the Canton sump, there are no bonnet clearance issues on this XY, even with the 2.6-litre supercharger perched atop the motor.

DOWN TO THE WIRE

WIRING is probably the single biggest mental hurdle car enthusiasts have to face with their project. Matthew finds the Coyote’s wiring simple provided you know from the outset whether or not you’re going to hop-up your engine.

“The Ford ECU and wiring loom is brilliant, because you only need to connect several wires and you can start the engine,” he says. “However, if you don’t want to get your Coyote swap dyno-tuned, then you need to keep the intake the same volume and path as the stock piece. The stock headers are so restrictive we get ours dyno-tuned, and the Ford Performance Aluminator twin-throttle intake manifold is worth another 50hp on top, too.”

FULLY ENGINEERED

POWER is nothing without control, and Matthew is adamant a Coyote-swapped 60s or 70s Ford needs significant chassis and suspension upgrades to be safe on the roads. This is why RRS spent bulk time ensuring its swap kit fits within engineering guidelines from around Australia, including going through finite analysis.

“A 2017 drivetrain needs 2017-spec chassis engineering,” Matthew says. “Everything has to work together; the steering geometry, the anti-dive characteristics and more all have to bring a 70s chassis into 2017. Anything less and you have a lethal weapon.

“The home fabricator is being squeezed by authorities more and more to ensure they are compliant and to make their cars safe and roadworthy,” he concludes. “We can’t get away with what we used to do building these cars back in the 70s, because even a stock Coyote has more power than a modified 351 did back in the day.”

IN DETAIL:

Coyotes love a bit of boost, and the XY has that handled thanks to a VMP 2.6L blower, which is an Eaton-style four-lobe unit similar to that offered by Roush in the US. “I have no idea how much boost we’ll run through this set-up; we need to get it all set up on the dyno first,” Matthew says. “We’ll aim for 780rwhp and go up from there, but it could make over 1000rwhp”.

RRS sells pre-stamped replacement notched shock towers, and also has DIY templates for those who want to do their own tower notch. This step is crucial when it comes to fitting a multi-cam V8 into early Falcons, as the heads would otherwise foul on the stock shock tower.

Matthew takes a pragmatic approach to cooling the blown V8: “This car uses an FG Falcon radiator, air conditioning condenser and fans, because you don’t get overheating problems in FGs. They’re lightweight, it makes hoses easy, and if something goes terribly wrong it can all be easily and cheaply replaced”.

The RRS-designed lower control arm, four-pot brake kit, coil-over strut and steering rack offer a big upgrade over the XY’s stock front end. “The original front suspension design put a huge additional load into the front of the car,” Matthew says.

Matthew and the RRS crew had to go with electric assistance for the steering, as a hydraulic pump won’t fit in a Falcon bay on the engine. To remedy this, a ZF electric power-steer pump out of a late-model BMW lives under the front guard, and is speed-regulated according to resistance.

The RRS kit allows you to fit an in-tank modular reserve assembly fuel pump system to a stock early Falcon tank by cutting a hole and bolting mounting bosses in place. “The pump has an in-built swirl pot,” Matthew says. “It uses different-height legs so you can set the depth in almost any fuel tank, and the pump can be upgraded to a Walbro with a simple plug-in pump. This set-up stops problems with fuel slosh, and it is nice and quiet – and legal”.

The 19×11 rear Intro billets fit thanks to the rear inners being mini-tubbed and reinforced and the removal of the factory wheelarch pressings. The bottom of the rear quarter panels were also pushed out 3cm each side. A 9in with a Strange centre and 31-spline axles gets the power to the ground. RRS suggests 3.5:1 diff gears for a car using a four-speed 4R70W auto, 3.25:1 for a six-speed 6R80, and 2.75:1 for a ZF six-speed.

1. The RRS three-link, with torque arm, reduces corner-exit oversteer and improves chassis rigidity. It is mounted to the 9in diff, which comes with a range of rear disc-brake options

2. The RRS kit runs adjustable QA1 coil-overs in the rear, as they can be easily tuned on the fly by owners who want to cruise, hit the track or go drag racing

3. The Jet-Hot-coated headers fit XK-XD Falcons, plus a range of left-hook Fords including Mustangs and Fairlanes

4. A side-mount under-dash brake booster opens up valuable engine bay space, and RRS has pedal kit options for manual or auto transmissions. This XY

uses an electronic throttle

5. Front disc brake options include 283mm, 297mm or 330mm rotors, with single-piston, Commodore two-pot or four-pot billet calipers available

6. The beefy RRS aluminium lower control arms are forged to the company’s specs, improving front-end rigidity, along with MacPherson coil-over

struts

7. Thanks to the kit’s modular design, RRS can offer 58 different steering racks for Fords by changing the spacing of the tie-rod ends, centre bracket angle, length of the extension housing and drag bar

8. The factory strut rods are upgraded with better bushes to eliminate geometry changes under emergency braking. The RRS engine mounts will fit both Coyote and 5.4 Boss quad-cam V8s

9. Long reinforcement plates are inserted into the XY’s sills and plug-welded, in order to bring the 70s chassis up to spec with the 2017 powerplant

10. his Coyote wears a Ford Racing Aluminator intake manifold, which will give it an immediate 50hp boost over the stock 435hp rating

Comments