This article was originally published in the February 2019 issue of Street Machine

THE foundation of engineering is a systematic and logical approach to problem-solving. Engineers start with the desired target before analysing and then optimising the system required to achieve it.

When it comes to brakes, the target is to achieve the desired line pressure. We want enough fluid-line pressure so that there is enough squeezing force at the wheels, with the brake pads gripping the disc with just the right force for optimal braking. A commonly accepted line-pressure target for a four-wheel disc brake set-up is 1200-1400psi. Personally, I like 1350psi as an ideal pressure.

Starting at the brake pedal, let’s say that a comfortable average foot force on the pedal is 80lb. With a 7:1 pedal ratio, that gives us 560lb of force at the pushrod. So pedal ratio is important for good braking; clearly, a low ratio can limit the performance of the whole system.

Starting at the brake pedal, let’s say that a comfortable average foot force on the pedal is 80lb. With a 7:1 pedal ratio, that gives us 560lb of force at the pushrod. So pedal ratio is important for good braking; clearly, a low ratio can limit the performance of the whole system.

The brake pedal is often the source of poor brake performance for other reasons, too. Whether it’s an underfloor pivoting type or hung from under the dash, the brake pedal should be set up so that as it is squeezed it moves towards the point where it is at a right angle to the pushrod, and then marginally on from that position for maximum efficiency. If maximum brake force is at that right-angle point, you’re off to a good start. If, however, the brake pedal is set up to start at the right-angle point or past that point, the pedal becomes less efficient as the brakes are applied and, in the worst case, risks going over centre to a position of no return. Lengthening the pushrod or changing to a different pedal design are simple solutions to this problem.

The pushrod connects to the booster – the next stage in the system. A good dual-diaphragm in-line booster that is receiving at least 20 inches of engine vacuum will give you another 750lb of force into the master cylinder. So vacuum is important, too. Check the vacuum being generated by your engine; if there’s not enough you won’t get to that desired 1350psi of line pressure. If your engine can’t develop the target vacuum due to a big cam, you can solve this by simply changing the vacuum source to a vacuum pump. But if the low vacuum is due to some other issue, you’ll need to solve that before moving on.

Put a vacuum meter on the inlet manifold and see what reading you get. If it’s low, check the inlet manifold for leaks by spraying brake cleaner around the gasket areas. If there’s a leak, the fluid will make the engine run rough as it gets into the nearest cylinder. Fix these problems and you’re on the way to braking excellence.

For the sake of this discussion, let’s imagine that we have a 11/8-inch-bore master cylinder. This master cylinder just happens to have about a one-square-inch piston area, so our 1310lb of force (560lb from the pedal and another 750lb from the booster) at the pushrod becomes 1310psi of line pressure. So we’re a bit short of my ideal 1350psi, but not by enough to cause a problem.

For the sake of this discussion, let’s imagine that we have a 11/8-inch-bore master cylinder. This master cylinder just happens to have about a one-square-inch piston area, so our 1310lb of force (560lb from the pedal and another 750lb from the booster) at the pushrod becomes 1310psi of line pressure. So we’re a bit short of my ideal 1350psi, but not by enough to cause a problem.

To now get the brakes up to optimum pressure, you can increase the pedal ratio and/or the booster size, or decrease the bore size of the master cylinder. For every 1/16-inch reduction in the master cylinder bore size, you can get a line pressure increase of up to 100psi, depending on the bore diameter. Remember though that decreasing the bore size increases the pedal travel required to displace the same amount of brake fluid, so that’s a compromise that must be taken into account.

In reality, 7:1 pedal ratios are not that common, but that is often made up for by a big production-car booster that pumps out 900lb of pushrod force, plus the pedal force. I see so many seven-inch single- and double-diaphragm boosters that have very poor performance and are the source of brake problems, but this has been ignored due to the convenience of using a small-diameter booster in tight spaces. If the booster can’t be changed, you’ll need to get to the line pressure target by other means.

If you understand these simple principles and start at the brake pedal and finish at the wheels when optimising your system, good brakes are only a few steps away.

STRIKING A BALANCE

BRAKE balance is best measured dynamically on the track, in order to see how the brakes are working in real driving situations and at different speeds.

BRAKE balance is best measured dynamically on the track, in order to see how the brakes are working in real driving situations and at different speeds.

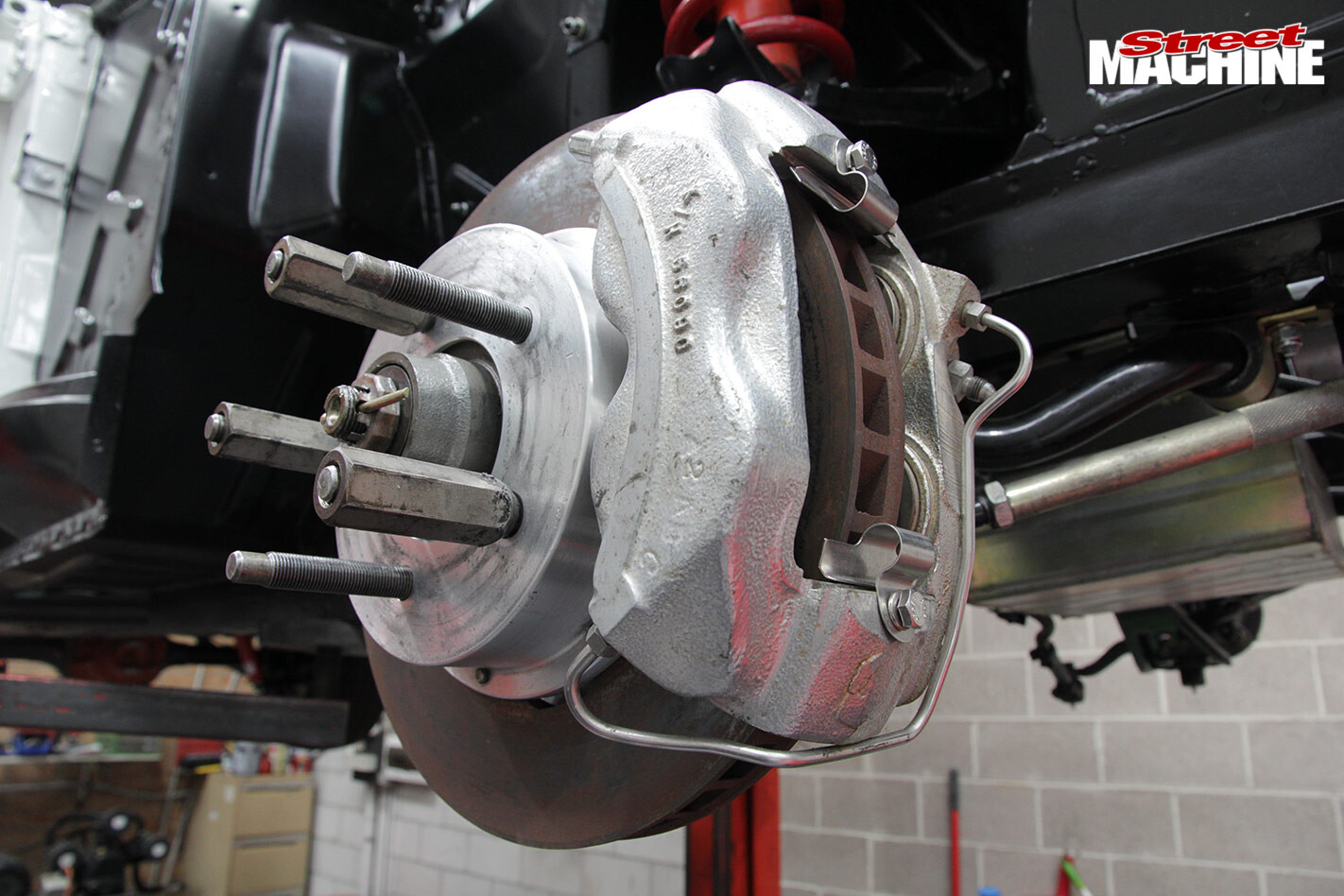

With disc brakes, balance is rarely a problem, and my preference is to avoid adjustable proportioning valves, which can clog up or jam, and make sure that the front-to-rear brake selection is right in the first place – remembering that 75 per cent of the braking is done by the front brakes in a crash stop.

Every good brake engineer can calculate the right rear-wheel cylinder size for a drum-brake rear end to match a disc-brake front set-up so that the system works well. Again, leave the proportioning valve out – it’s just another item to go wrong or leak in a system that doesn’t need it!

Every good brake engineer can calculate the right rear-wheel cylinder size for a drum-brake rear end to match a disc-brake front set-up so that the system works well. Again, leave the proportioning valve out – it’s just another item to go wrong or leak in a system that doesn’t need it!

BRAKE LINE PRESSURE

THERE are other ways to measure brake line pressure if you are having trouble with the calculation method I’ve outlined. Pressure gauges and adapters are available from Wilwood, Speedway, Auto Meter, Kent-Moore and others. These are usually fitted in place of the bleed nipple at one wheel, and when foot pressure is applied the true line pressure is shown on the gauge.

THERE are other ways to measure brake line pressure if you are having trouble with the calculation method I’ve outlined. Pressure gauges and adapters are available from Wilwood, Speedway, Auto Meter, Kent-Moore and others. These are usually fitted in place of the bleed nipple at one wheel, and when foot pressure is applied the true line pressure is shown on the gauge.

Similarly, engine vacuum can be checked by attaching a 0-25inHg vacuum gauge to a hose that’s connected to manifold vacuum on the engine, such as at the brake booster take-off point. Ensure that you use a proper vacuum hose so that it doesn’t suck in and give a false reading

Similarly, engine vacuum can be checked by attaching a 0-25inHg vacuum gauge to a hose that’s connected to manifold vacuum on the engine, such as at the brake booster take-off point. Ensure that you use a proper vacuum hose so that it doesn’t suck in and give a false reading

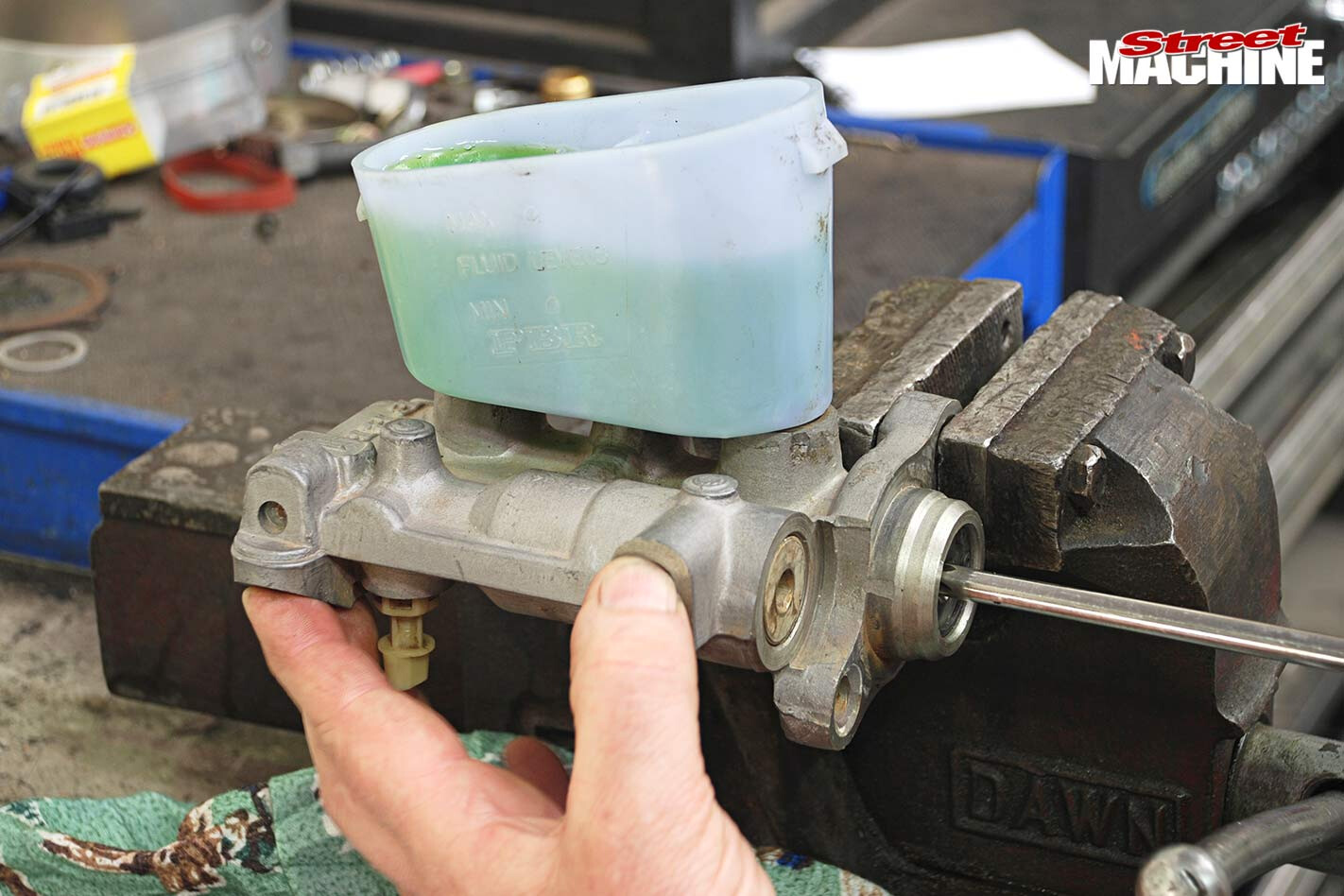

MASTER CYLINDERS

Master cylinder bore diameter – or more specifically, piston area – is a critical consideration when calculating brake line pressure. In Dr Tim’s example, a 11/8in-bore master cylinder has a piston area of roughly one square inch, yielding a 1:1 transfer of force from the pushrod to pressure in the brake line fluid

Master cylinder bore diameter – or more specifically, piston area – is a critical consideration when calculating brake line pressure. In Dr Tim’s example, a 11/8in-bore master cylinder has a piston area of roughly one square inch, yielding a 1:1 transfer of force from the pushrod to pressure in the brake line fluid

DRUM BRAKES

In drum brake applications, wheel cylinder size must be factored in when aiming for optimum front-to-rear braking balance. In a street car, it is Dr Tim’s preference to do the maths and set the system up correctly from scratch, rather than relying on a proportioning valve to correct a problem that doesn’t need to exist

In drum brake applications, wheel cylinder size must be factored in when aiming for optimum front-to-rear braking balance. In a street car, it is Dr Tim’s preference to do the maths and set the system up correctly from scratch, rather than relying on a proportioning valve to correct a problem that doesn’t need to exist

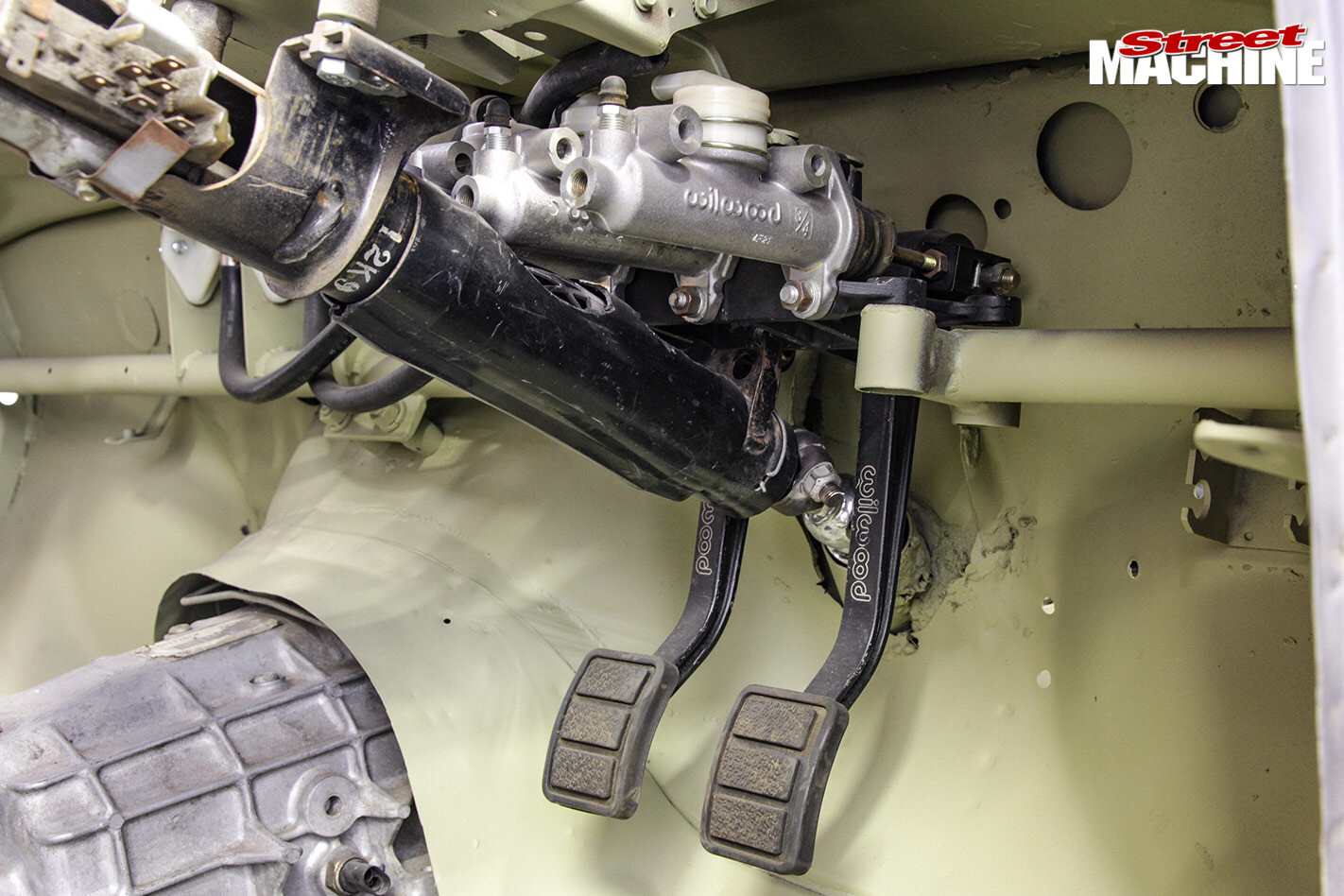

PEDAL BOXES

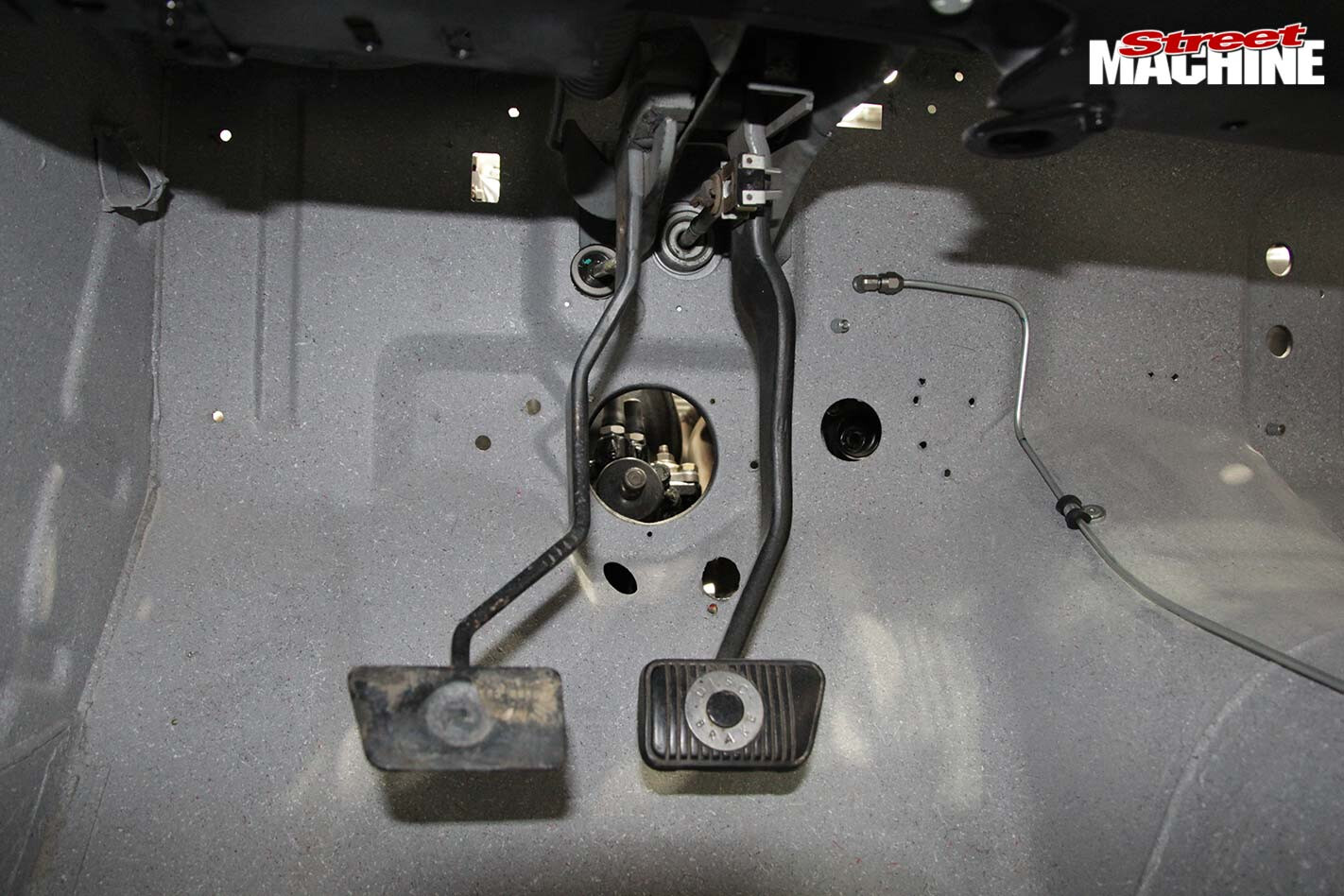

Aftermarket pedal boxes like this Wilwood product are engineered with optimal pedal ratios, pushrod angles and master cylinder bore diameters in mind. This set-up features remote reservoirs which are mounted under the dash and accessed via the cowl panel, and is fitted to Damien ‘Chubby’ Lowe’s VB Commodore

Aftermarket pedal boxes like this Wilwood product are engineered with optimal pedal ratios, pushrod angles and master cylinder bore diameters in mind. This set-up features remote reservoirs which are mounted under the dash and accessed via the cowl panel, and is fitted to Damien ‘Chubby’ Lowe’s VB Commodore

BOOSTER BRACES

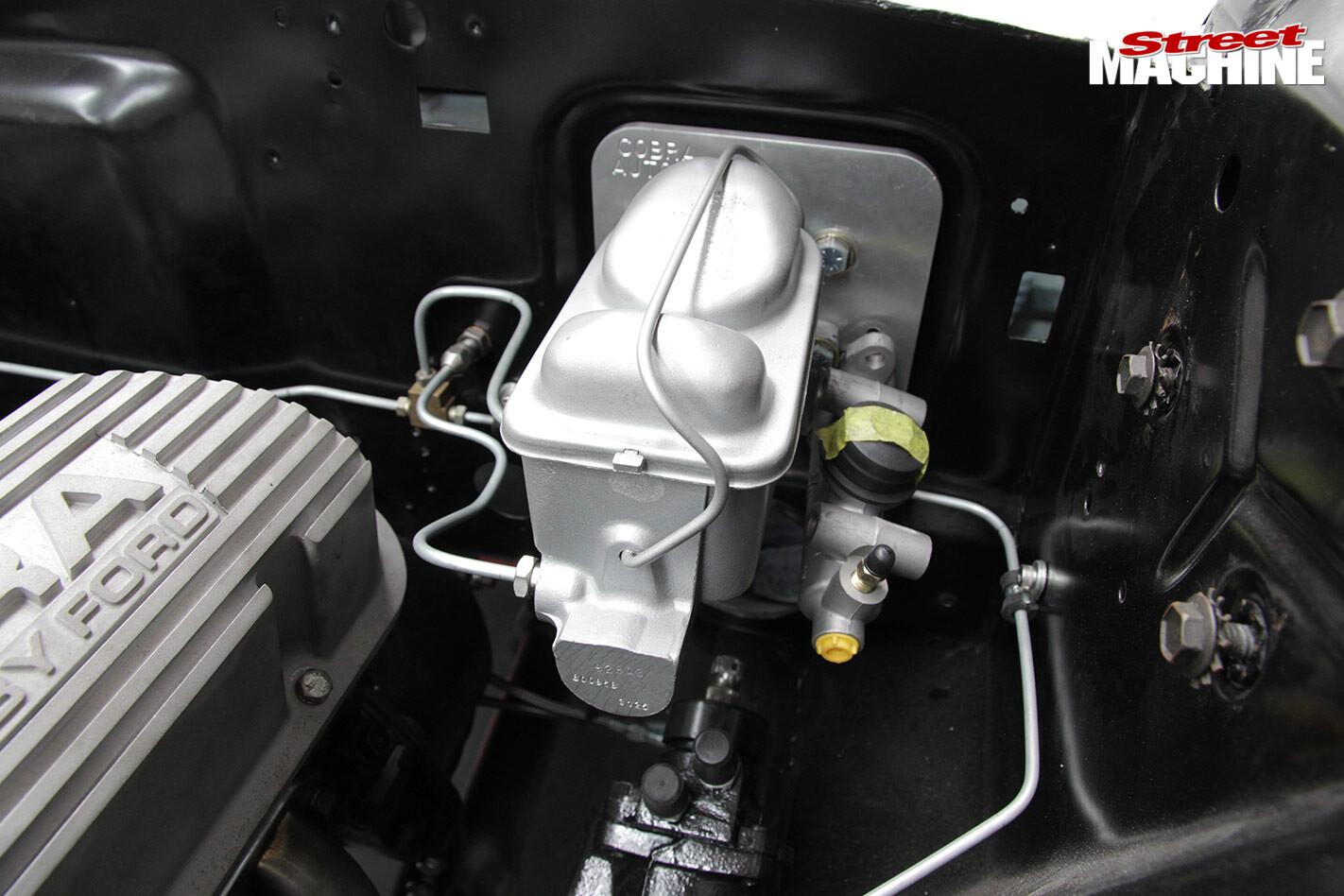

The factory-fitted brake booster brace on this HK Monaro helps prevent lateral movement of the booster and master assembly when pedal force is applied, maximising longitudinal transfer of force from the pedal through the pushrod and into the master cylinder. Also note the check valve on the booster, which only allows vacuum to travel from the intake to the booster, and not the other way

The factory-fitted brake booster brace on this HK Monaro helps prevent lateral movement of the booster and master assembly when pedal force is applied, maximising longitudinal transfer of force from the pedal through the pushrod and into the master cylinder. Also note the check valve on the booster, which only allows vacuum to travel from the intake to the booster, and not the other way

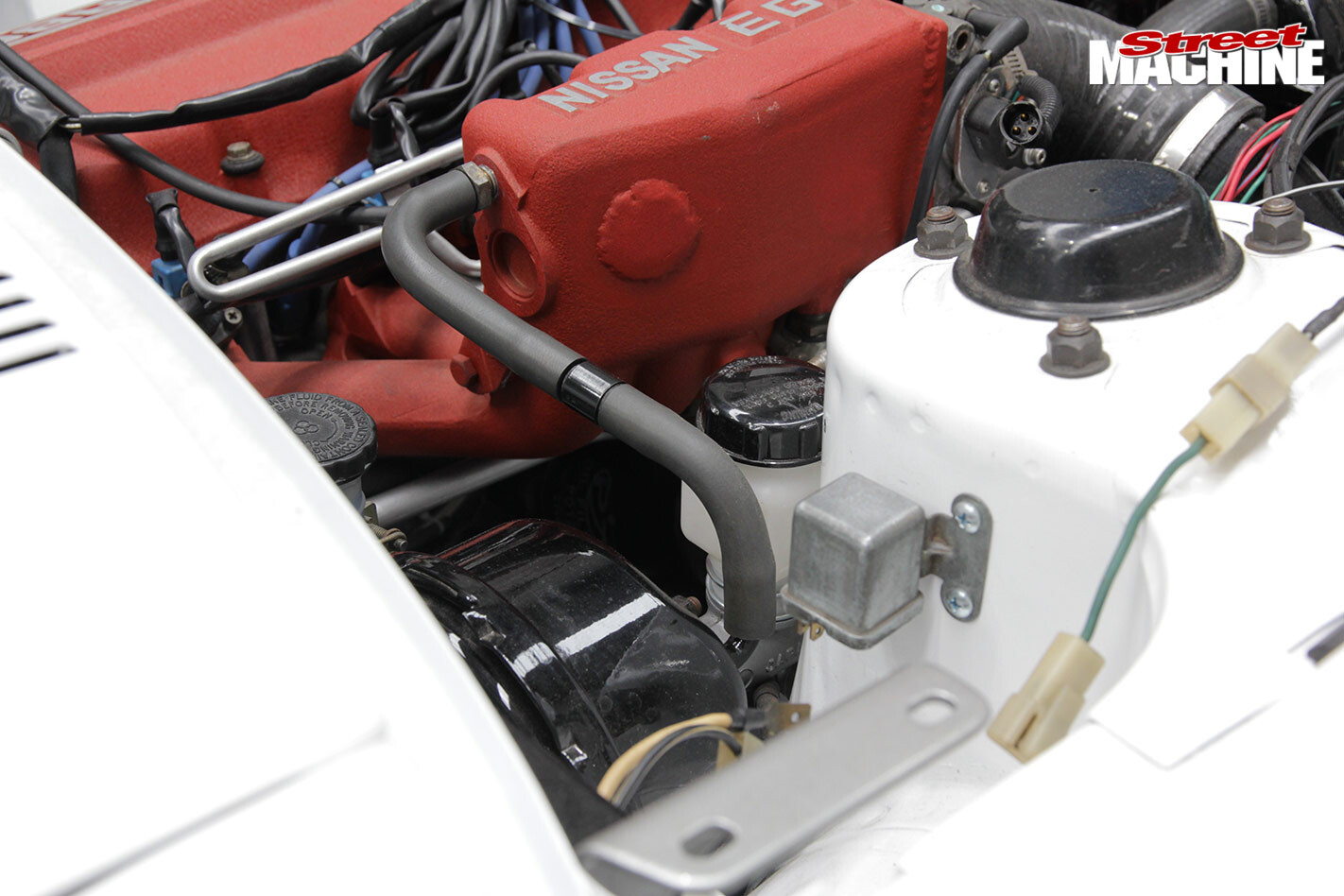

VACUUM

This is the vacuum feed between the intake manifold and the brake booster in a Nissan Z18-swapped Datsun. It’s the easiest place to measure engine vacuum when diagnosing a potential brake line pressure issue. If your engine is fitted with an aftermarket camshaft, you may have to resort to a vacuum pump to achieve a desirable level

This is the vacuum feed between the intake manifold and the brake booster in a Nissan Z18-swapped Datsun. It’s the easiest place to measure engine vacuum when diagnosing a potential brake line pressure issue. If your engine is fitted with an aftermarket camshaft, you may have to resort to a vacuum pump to achieve a desirable level

of vacuum

BOOSTER DELETE KITS

This Mustang race car has been fitted with a booster delete kit, which is not recommended for street use. A firmer pedal with less initial bite and more progressive feel is arguably preferable for motorsport applications

This Mustang race car has been fitted with a booster delete kit, which is not recommended for street use. A firmer pedal with less initial bite and more progressive feel is arguably preferable for motorsport applications

FACTORY PEDALS

Factory brake pedal set-ups have a great deal of engineering smarts invested in them at an OE level. Unless an engine conversion creates booster clearance issues or you’re building a show car and aiming for a clinically clean firewall, sometimes it’s best not to try and reinvent the wheel

Factory brake pedal set-ups have a great deal of engineering smarts invested in them at an OE level. Unless an engine conversion creates booster clearance issues or you’re building a show car and aiming for a clinically clean firewall, sometimes it’s best not to try and reinvent the wheel

Comments