MINI-tubs can provide clearance for a lower stance and bigger wheel-and-tyre combo for your ride, and the resultant look is something all street machiners lust after. The good news is that knocking up a set of tubs is a lot easier than you may think. Here’s how it’s done!

This article was first published in the March 2019 issue of Street Machine

1. It’s a fair understatement to say things look like a dog’s breakfast back here, with decades of poorly executed patch work and rust holes making the decision to replace both full wheel tubs on this 50s Chrysler a lot easier. Since we’re after a slightly more aggressive appearance than factory, things will be beefed up, giving the edges a smaller radius to create a shoulder and adding more width with a centre strip to create the desired look.

1. It’s a fair understatement to say things look like a dog’s breakfast back here, with decades of poorly executed patch work and rust holes making the decision to replace both full wheel tubs on this 50s Chrysler a lot easier. Since we’re after a slightly more aggressive appearance than factory, things will be beefed up, giving the edges a smaller radius to create a shoulder and adding more width with a centre strip to create the desired look.

2. Keeping close to the factory size, the wheel tub is sectioned down the middle at its tallest point, and this is used to lay out our template. The outside edge is traced onto a sheet of 1mm steel. This will become the inner part of the tub.

2. Keeping close to the factory size, the wheel tub is sectioned down the middle at its tallest point, and this is used to lay out our template. The outside edge is traced onto a sheet of 1mm steel. This will become the inner part of the tub.

3. The traced area is cut out and duplicated onto a second piece of sheet metal to form the outer side of the tub, closest to the quarter. Extra sheet is marked out before cutting to allow for the lower lip that needs to meet the inside of the quarter panel. Circumference and width measurements are then scribed onto a third rectangular section of sheet and cut. With slightly more girth than the factory tub, this third piece will make the centre strip.

3. The traced area is cut out and duplicated onto a second piece of sheet metal to form the outer side of the tub, closest to the quarter. Extra sheet is marked out before cutting to allow for the lower lip that needs to meet the inside of the quarter panel. Circumference and width measurements are then scribed onto a third rectangular section of sheet and cut. With slightly more girth than the factory tub, this third piece will make the centre strip.

4. The outer edge of the centre strip is marked from end to end with a gradual curve, meeting in the centre. This will allow the outer side of the wheel tub to taper inwards towards the top, allowing clearance for the inside top of the quarter panel. Having the inner, outer and centre sections of sheet metal sorted, it’s a good time to lay all three patterns out and duplicate them for an exact match to the opposite side of the vehicle.

4. The outer edge of the centre strip is marked from end to end with a gradual curve, meeting in the centre. This will allow the outer side of the wheel tub to taper inwards towards the top, allowing clearance for the inside top of the quarter panel. Having the inner, outer and centre sections of sheet metal sorted, it’s a good time to lay all three patterns out and duplicate them for an exact match to the opposite side of the vehicle.

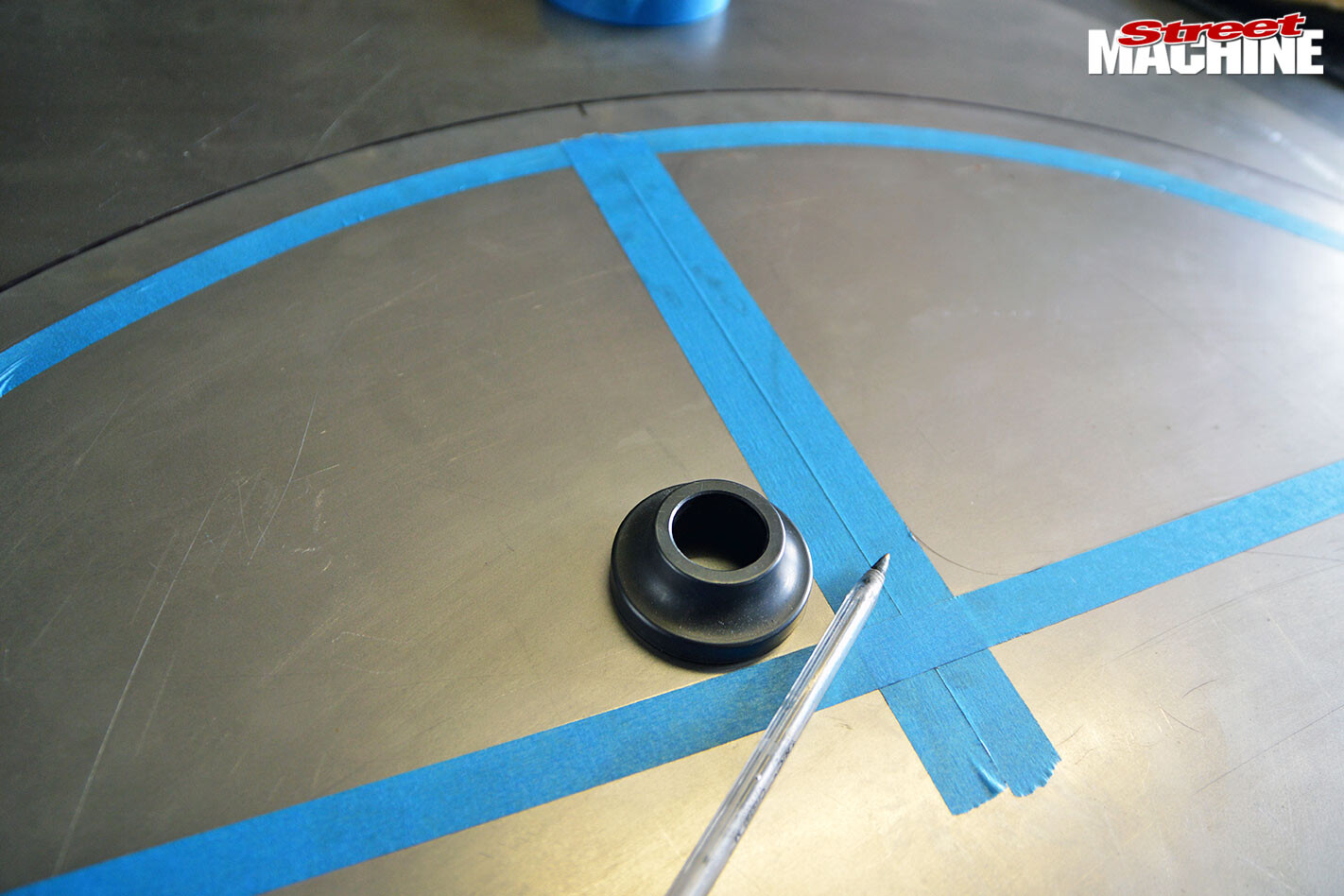

5. As this is an old Chrysler Wayfarer ute, I decided to give the tubs some character rather than having them completely smoothed out. A quick design is laid out with some 18mm tape.

5. As this is an old Chrysler Wayfarer ute, I decided to give the tubs some character rather than having them completely smoothed out. A quick design is laid out with some 18mm tape.

Sign-up here for your free weekly report on the world of Street Machine

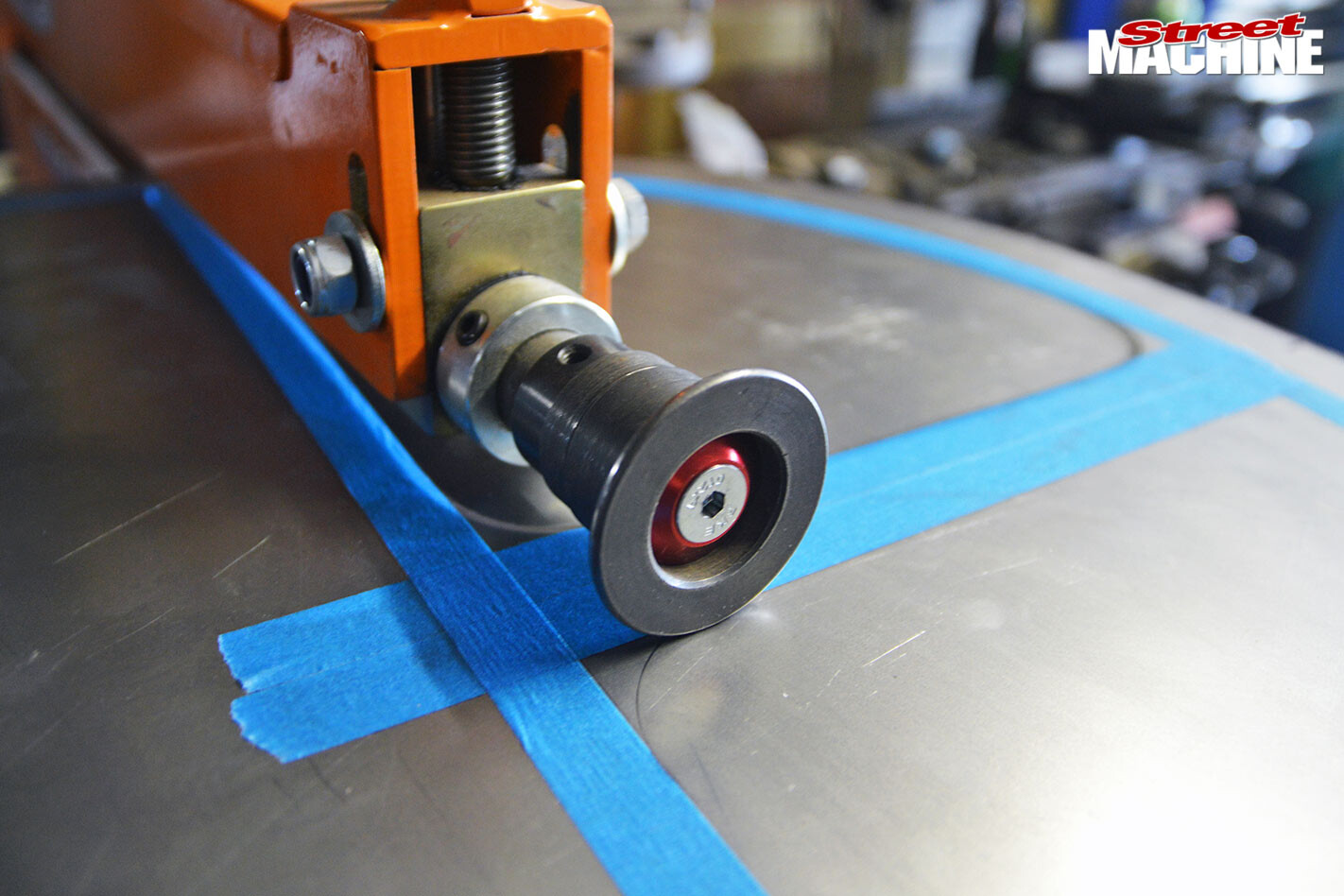

6. The pieces are then worked with the bead roller. This isn’t only for looks; any kind of indentation/extrusion will add slight rigidity to a panel, which is handy when it comes time to weld.

6. The pieces are then worked with the bead roller. This isn’t only for looks; any kind of indentation/extrusion will add slight rigidity to a panel, which is handy when it comes time to weld.

7. A swap-out of dies and it’s back into the bead roller to roll 45-degree shoulders. The same thing can be achieved by shaping a shoulder into a piece of wood and forming the sheet over that. The bead roller is a just a more efficient method.

7. A swap-out of dies and it’s back into the bead roller to roll 45-degree shoulders. The same thing can be achieved by shaping a shoulder into a piece of wood and forming the sheet over that. The bead roller is a just a more efficient method.

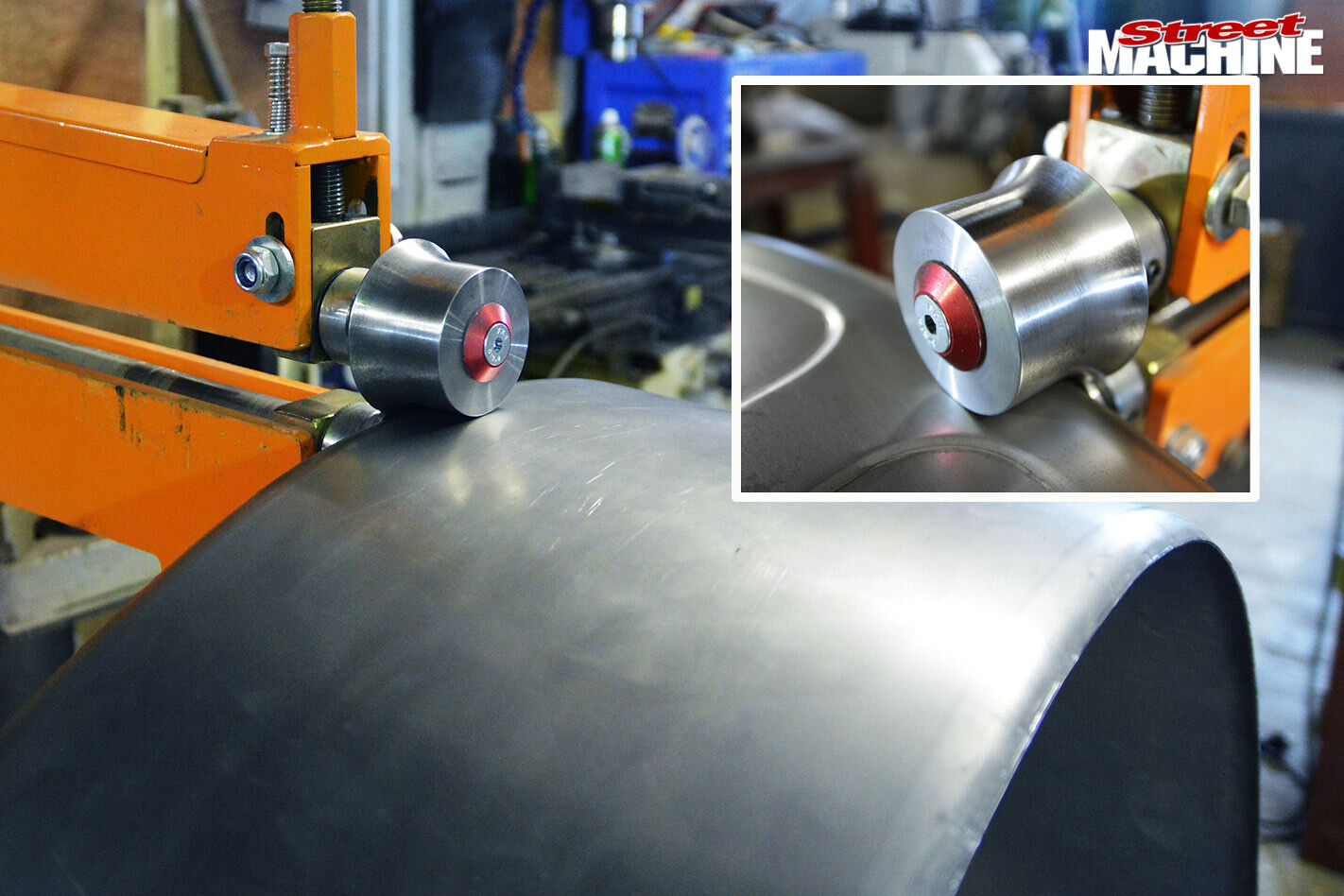

8. Now the inner and outer sides and both sides of the centre piece all have a 45-degree shoulder, which will create a 90-degree shoulder on both sides once everything’s joined together. A touch-up in the shrinker/stretcher and a few more passes with the bead roller are required to get our curves a little more precise.

8. Now the inner and outer sides and both sides of the centre piece all have a 45-degree shoulder, which will create a 90-degree shoulder on both sides once everything’s joined together. A touch-up in the shrinker/stretcher and a few more passes with the bead roller are required to get our curves a little more precise.

9a. The trio of panels are now aligned, which can be a bit of a bastard. Tack-welding the centre and moving out to the sides, slightly tweaking things as you go, will get it there.

9a. The trio of panels are now aligned, which can be a bit of a bastard. Tack-welding the centre and moving out to the sides, slightly tweaking things as you go, will get it there.

9b. Once tacked into place, it’s time to trial-fit. With everything looking good and sitting as it should, you can then fuse-weld things together with the TIG.

9b. Once tacked into place, it’s time to trial-fit. With everything looking good and sitting as it should, you can then fuse-weld things together with the TIG.

COMPARE

Next is a rough tune-up with an assortment of hammers and dollies to flatten the weld and knock things into shape. After a quick whiz-over with the sander, there you have it: a new wheel tub!

Next is a rough tune-up with an assortment of hammers and dollies to flatten the weld and knock things into shape. After a quick whiz-over with the sander, there you have it: a new wheel tub!

BEFORE & AFTER:

Fine-tuning, trimming and making the lip on the outer to join the quarter panel is still required, as is fitting the new tub into the Chrysler and fabricating all the other steel around it, but that is another story!

Fine-tuning, trimming and making the lip on the outer to join the quarter panel is still required, as is fitting the new tub into the Chrysler and fabricating all the other steel around it, but that is another story!

Of course, this is only a quick run-down of the processes I used. There are plenty of other techniques out there. Tubs can also be purchased as off-the-shelf items, but then you will end up having the same generic part as everyone else. Nothing beats the sense of satisfaction gained from fabricating your

Of course, this is only a quick run-down of the processes I used. There are plenty of other techniques out there. Tubs can also be purchased as off-the-shelf items, but then you will end up having the same generic part as everyone else. Nothing beats the sense of satisfaction gained from fabricating your

own parts!

Comments