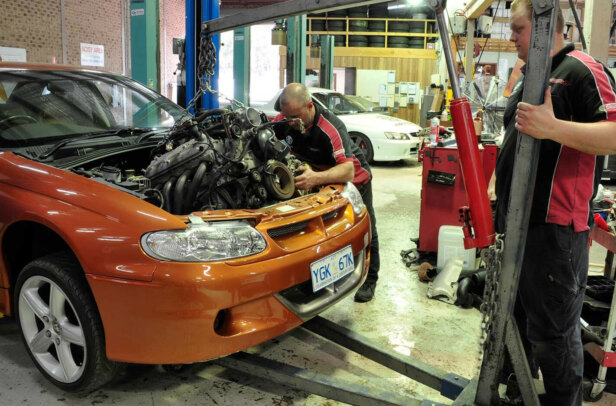

LAST month we dealt with engine size requirements under the National Guidelines, so now it seems logical to talk about other key issues to consider when fitting an engine to your project car.

EMISSIONS

Let’s start with emissions. The requirements to limit gaseous emissions was introduced in ADR 26 in 1972, when passenger vehicles had to be fitted with a positive crankcase ventilation (PCV) system to prevent blow-by gasses escaping to the atmosphere, and carbon monoxide emissions were also limited. The requirements became progressively more stringent, and ADR 79 and 80 – the current rules – now apply to all new light and heavy vehicles.

All passenger vehicles built on or after 1 July 1976 are required to be fitted with an effective evaporative emission control system to comply with ADR 27A. This system comprises a carbon canister connected to the fuel tank and induction system.

In addition, all passenger vehicles built on or after 1 January 1986 have to be fitted with an engine that complies with ADR 37 and runs on unleaded fuel. These vehicles initially had to be fitted with a narrow fuel filler neck, but this is no longer mandatory because unleaded is now the only fuel available.

What this means for modifiers working on cars built after 1949 is that you must match your engine choice to the year of the vehicle. Your local Department of Transport will summarise this point by saying that “you can’t downgrade a vehicle by fitting a higher-emission engine”. As an extreme example, you can’t fit a 1969 Chevrolet V8 into a 1996 vehicle! I’m sure we all knew that anyway, but as you can see, there will be cases where a 1985 engine cannot be fitted to a 1986 vehicle, so your understanding of the break points is critical.

On the other hand, it’s equally important to note that later-model engines with better emission levels can be fitted to older cars, as that kind of modification represents an emission upgrade to that vehicle and will always be approved.

POSITION, POSITION, POSITION

WHAT about engine position? Most engine installers put the engine as close to the firewall as possible to give room for the radiator and fan at the front. How close can it be? It’s the well-known Dr Tim’s finger distance! In generous engine bays this is not critical.

In cars with manual gearboxes, you need to make sure that the gear shifter ends up in a practical place relative to the front seat; otherwise a shift adapter will be needed. In automatics, there are so many flexible cable shifters available that make the gearbox position much less important.

The sump needs to clear suspension and steering. Laterally, you need to think about steering clearance, and it is very important to be able to mock up the steering at the same time as the engine. It is not unreasonable to put the engine centreline 25-30mm to the passenger side to help with steering clearance when needed. In general, the steering engineering should be put before the exhaust; it’s more important! We’ve all seen installations where the steering was done last, and it can be pretty ugly.

Engine height is generally dictated by the gearbox position, so that the floor clearance and tailshaft connection make sense. Remember suspension and cross-steering component clearances as well. In a new build, it is customary to put the gearbox output shaft in the right place for floor clearance and gearbox or chassis crossmember location, and then ensure that the engine’s inlet manifold is horizontal. Now chock the engine in that spot and start fabricating the engine mounts.

Speaking of the latter, I’m a keen advocate of distributing the engine torque through to the vehicle chassis or subframe. Engine mounts should not be mounted off the chassis rails alone, because that method applies unbalanced torsional loads to those rails. Engine cross-tubes resist those torsional loads and turn the forces into vertical components that the rails are designed to deal with. A benefit of an under-engine mounting tube is that it protects the sump from damage.

Another common method of achieving the same thing is to mount the engine from the front suspension crossmember, like many manufacturers do. Try where possible to use factory engine mounts that have a built-in safety collapse mechanism, so that if the mount fails the engine doesn’t fall onto the steering.

Once mounted, the engine inlet manifold should be horizontal, so it is also important to know what attitude the vehicle is going have at normal ride height to give this end result. You need to think about all of the elements.

LINES & HOSES

Finally, it’s time to think about engine services. Bring the fuel up the chassis with solid line, clamped to the chassis near the end with a flexible hose across to the engine. If the fuel pump is electric, make sure there is a tachometric, oil pressure or computer cut-off that stops the fuel pump when the engine stops. This is critical in a crash scenario.

Simple, well-engineered steering is important. Make the exhaust go around the steering, not the other way around.

Wiring should come through grommetted holes in the firewall and all firewall holes should be sealed to keep fumes out of the cabin. For the brake booster, use approved vacuum hose that has a thick wall to avoid collapse under vacuum.

Make sure the accelerator mechanism can open to full throttle! It is a very common fault found by engine tuners that full throttle is limited by the cable, linkage or pedal rather than the butterfly.

NOTE: Of course, I acknowledge the fact that cars are being built by modifiers every day that fall outside of these guidelines, and this is the choice everyone has. But as an engineer, it is my responsibility to only certify legal vehicles, so that in the event of a problem or accident there is no issue with the authorities or insurance.

GOLDEN RULES

- If you are modifying a pre-1972 vehicle, the majority of engines available can be fitted because emission rules do not apply. These are the cars to build! Remember engine size rulings though.

- For cars built after 1972 but before 1 July 1976, an engine with a PCV is suitable. This is still a very simple situation and most available engines can comply, making this an attractive option for modifiers.

- After 1 July 1976 but before 1 January 1986, the emission system consisted of the PCV, evaporative emissions control (carbon canister system) and exhaust gas recirculation, and that needs to be maintained and operate properly. Most later-engines can be made to comply, but older smog engines will not.

- After 1 January 1986, engines that were originally designed to run on unleaded fuel and meet tighter emissions standards must be fitted to those vehicles. Catalytic converters may need to be fitted.

- After 1989, it is important that engines are completely matched to the year of the vehicle being modified to ensure compliance with the ever-increasing emission requirements and avoid issues with the Department of Transport and police.

- Where unleaded engines, or engines converted to unleaded, are used in pre-1986 vehicles, catalytic converters are not required, but may be fitted. However, for vehicles built after 1 January 1986, cats must be fitted.

- Aftermarket engine management computers do not guarantee compliance with the relevant ADR for emissions; only genuine factory units do.

- Fitting of aftermarket turbos and superchargers will change emissions and, for legality, is best carried out on pre-1986 vehicles.

- For highly modified ‘elite’ street machines built to Individually Constructed Vehicle (ICV) rules, the engine choice must usually meet current emission rules or be able to run on gas.

Comments