WHILE Barra and LS sycophants fill the internet with incessant bleating about which junkyard engine is best, the rest of us got properly excited when Ford whipped the covers off its 2020 F250 Super Duty pick-up truck. The Blue Oval walked away from traditional cam-in-block V8s in the late 90s, but its latest pick-’em-up has gone back to an overhead-valve pushrod design and big cubes. Say hello to Ford’s ‘Godzilla 7.3’.

First published in the February 2021 issue of Street Machine. Photos: Ford & Matt Reekie

Named after the fabled King of the Monsters, Ford’s new engine should have street machiners excited. While the 5.0-litre Coyotes and Mod motors have been increasing in popularity of late, the sheer size of their overhead-cam cylinder heads and expense make them less appealing to punters repowering cars.

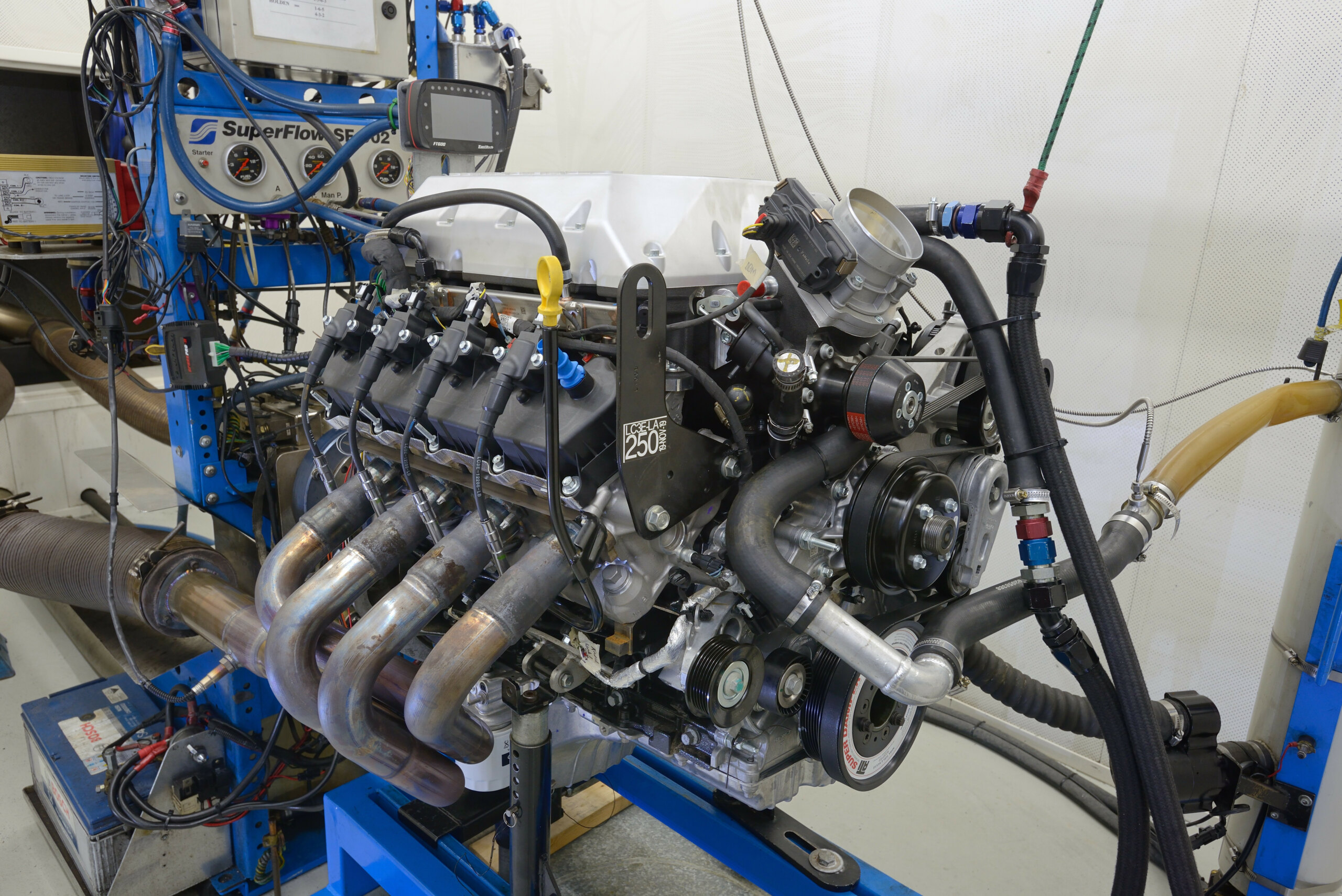

Aspirated Godzilla combos with a mild cam have made up to 600hp on an engine dyno, while a spicier aspirated combo went 790hp. Running on C16, that engine featured Wiseco 12.5:1 pistons and MGP aluminium rods, a Charlie Westcott mechanical-roller cam, billet intake, Jesel keyed lifters, Trend pushrods, 90mm drive-by-wire throttlebody off a GT350 Mustang, upgraded rockers and titanium valves. And that’s before they fitted the Whipple 3L blower! Godzilla sells for US$8150 through Ford Performance Parts in the USA, coming with an 80mm drive-by-wire throttlebody, plastic intake manifold, exhaust manifolds, ignition coils, 7.5L aluminium sump and a factory flexplate

In production trim, the 7.3-litre, 90-degree V8 spits out 320kW (430hp) at 5500rpm and a stump-pulling 644Nm (475 lb-ft) of torque at 4000rpm. That may not sound like a whole lot, but remember, this is in bone-stock production trim for use in giant workhorse pick-up trucks, vans and commercial vehicles, where reliability and longevity is key.

Going by online sources, the Godzilla tapes up very close to a traditional small-block Ford at 730mm long (timing cover to rear of block), 585mm wide (across valve covers) and 635mm high. This means it is approximately 5cm wider across the rocker covers than a 351 Windsor, and approximately 3cm longer. It weighs in at a hefty 263kg (580lb), thanks in part to the iron block, the upside of that being enhanced durability and longer life expectancy.

The cylinder heads flow a healthy 320cfm on the intake side and feature super-high intake ports for improved flow. Their flat flanges avoid bore distortion, as do the deep-threading 1/2in cylinder head bolts, while four-layer steel gaskets provide excellent sealing

With a 107.2mm bore and 101mm stroke, the Godzilla spans 7.3 litres, or 445ci in the old money, yet Ford considers the engine a small-block due to the 245mm (9.65in) deck height and tight 11.53mm bore spacing. The iron block is skirted for increased strength and features extra external webbing for improved rigidity.

With six-bolt mains and a forged steel crank, the Godzilla looks to be a stout package, especially as Ford claims that much of the design of the 10.5:1-comp cast aluminium slugs carries over from the twin-turbo EcoBoost performance motors. Additionally, piston-cooling oil squirters help cool the back side of the slug and prevent detonation under heavy load, and this is all controlled by the variable-displacement integrated oil pump.

Chain-driven off a crank-mounted sprocket ahead of the timing chain, that variable-pressure oil pump could provide issues when it comes to fitting the engine into cars with lower ride heights, as it affects clearance around the factory 7.5-litre aluminium sump. Similarly, the Godzilla comes equipped with an integrated oil cooler on the oil pan, sitting on the left-hand side.

As the OE variable cam timing has up to 50 degrees of movement in the cam, punters wanting high-lift-and-duration cam swaps will need to flycut the OE pistons for clearance to the intake valve. Cam timing lockout kits will likely hit the aftermarket soon, as these products already exist for overhead-cam Mod motors and GM pushrod engines

Michigan-based Team Z Motorsports fitted one into a Fox-body Mustang back in January 2020, and it apparently dropped in place with a Mustang 10-speed auto once the factory oil cooler was removed. Team Z stated its intention to produce a kit to relocate or delete the oil cooler, which Ford had intended more for heavy-duty towing applications.

The variable-pressure oil pump and factory variable cam timing mean that ECU choice will be key. Nearly every Godzilla we’ve seen running in the USA is wired with an OE-style computer from OBR; however, Haltech is keen to do R&D, and Holley has also indicated its desire to work on an ECU that will control all the factory features.

While General Motors has moved its pushrod engines to direct injection, the Godzilla uses more traditional port-style fuel injection and also features an 80mm drive-by-wire throttlebody on the composite intake manifold. The intake sits above a dry valley and mounts on a flat surface to improve sealing to the aluminium cylinder heads, which include steeply angled intake ports and progressive-rate beehive valve springs, with 55mm intake valves and 42mm exhaust valves.

The Godzilla runs a 1-5-4-8-6-3-2-7 firing order. There is no keyway on the crank for the balancer, and the bellhousing bolt pattern is a carry-over from the 4.6/5.4L Mod motors and 5.0L Coyote

Ford claims the wedge-shaped combustion chamber and centralised sparkplug location allow a higher compression ratio for improved efficiency and performance, while the heads boast a shallow valve angle to keep valves away from the cylinder wall, which improves flow. Godzilla wears forged aluminium rockers using nitrided roller bearings, which work with the hydraulic-roller lifters and single-phase variable valve timing, while the cam uses nine 60mm bearing journals to reduce deflection.

Ford Performance Parts recently announced its plan to release a control pack for the Godzilla, which will simplify the process of swapping the motor into an older car. In much the same vein as Chevrolet Performance’s highly successful Connect & Cruise packs, the kit is slated to come with an ECU, wiring harness, drive-by-wire throttle pedal and airbox assembly.

The first iteration of these control packs will cater to auto transmissions, with a manual variant to follow at some stage. The hot-up arm of the Blue Oval is also developing front drive-assembly options for Godzilla swaps, along with bare blocks and head castings, crankshafts and individual componentry. Ford Performance Parts’ Mike Goodman also confirmed the existence of a far spicier Godzilla engine that will be coming, codenamed ‘Megazilla’.

So far Whipple and ProCharger have both released blower options for the new 7.3-litre. The Whipple Stage 2 Gen 5 is a water-to-air-intercooled, 3.0-litre top-mount unit, and is claimed to inflate a Godzilla from the 430hp touted in the user manual to 700hp at the flywheel and over 1000Nm. Meanwhile, ProCharger’s P-1SC-1 side-mounted to a similarly stock Godzilla made “over 600hp” on a claimed 6-8psi.

With the similarities of the pistons to EcoBoost slugs and the big end of the Godzilla rods the same size as a Coyote rod, Wiseco has pistons and Callies has forged pistons and rods already on the shelf to handle 1400-1500hp. Engine designer Brian Wolfe feels the Godzilla’s capacity limit is around 470-480ci due to the compact design of the pistons not leaving a lot of room to move the pin up. Similarly, he pointed to the powdered metal rods (with Torx-bit fasteners) as another area where serious builders want more strength. With injector bosses cast into the cylinder head, punters wanting to carby-swap the Godzilla will have issues. Interestingly, the front drive accessory idlers (and water pump housing) are all part of the one-piece aluminium timing cover, while one of the radiator hoses faces downwards off the left side of the water pump

As the aftermarket race to develop parts for the new engine intensifies, at least one shop in the USA has broken the 1100hp barrier with two turbos strapped to a largely stock Godzilla (see sidebar, pp 110-111), and more are promising to push this motor hard.

Australia’s Herrod Performance enjoys close ties to Ford Performance in the USA, and bossman Rob Herrod confirmed there’s a 7.3 Godzilla crate motor on its way to the company’s Melbourne facility at the time of writing this story.

We can’t wait to see these bad boys start popping up in the junkyards and through crate engine resellers, as they are sure to make huge juice with the right parts bolted on!

HUNDREDS & THOUSANDS

YES, you read that correctly. Scott Merkel from Merkel Race Engines (MRE) in Hauppauge, New York set the internet ablaze when he made more than 1100hp on an engine dyno with a basically stock Godzilla.

The performance engine shop strapped a pair of VS Racing 7875 turbos and Frozen Boost water-to-air intercoolers onto the 7.3L Ford, plumbed a set of ID1050X injectors into the heads and tapped a 15psi tune into the OBR Euro-8 ECU. That’s it, right down to the OE valve springs!

“I’ve been aware of this engine and its development for roughly four years, as my brother Todd is a Ford engineer and has been on the development team designing and testing the Godzilla,” says Scott. “We already knew this thing is a beast and worth the effort in creating multiple performance versions.”

MRE did preliminary tests on aspirated combos running pump 93MON fuel (which is slightly spicier than our 98RON premium unleaded), before hooking the boosty boy up with Sunoco 112 race gas. It all forms part of a plan MRE has to plumb the depths to find Godzilla’s weak spots.

“We need to figure out what breaks before we can fix it, but so far we have been unsuccessful in our attempt to tear this thing up!” Scott laughs. “I believe we lacked sufficient valve spring tension to increase boost beyond 15psi. The immediate plans are to increase valve spring tension and run more boost on the otherwise bone-stock engine. Then we can complete the task of finding the strength limits, and subsequently upgrading the failed parts.”

While we’re used to seeing four-digit power figures these days, it is still impressive to even an experienced crew like MRE to draw such power out of what is essentially a box-fresh engine.

“I was impressed by the ease with which we were able to make over 1100hp,” Scott says. “The turbo project was built in the dyno room in one day on a bone-stock engine. A day later, this thing spat out 1114hp!”

Scott points to the engine’s size and ability to breathe as reasons for fellow boost fans to get excited about this new offering from Ford.

“This engine has a real good induction system, is not short on volume, and is rugged enough in stock form to make some impressive figures,” he says. “I believe the Mod motor will have a following for years to come, as Ford doesn’t seem to have immediate plans to put a Godzilla into a factory car, but performance transplants are another story. I’ll attempt to push the aftermarket envelope to make Godzilla transplants cost-effective and sensible in just about any vehicle.”

Interested Aussies can get their hands on some of this MRE action from Scott and crew at merkelracing.com.

“Complete plug-and-play solutions are available right now,” he says. “We are currently developing many naturally aspirated versions, including a very reliable plug-and-play 600hp engine. We will also have staged engine kits, with cams, springs, retainers, pistons, connecting rods and the like available.”

Comments