WHILE many turn their nose up at Holden’s 253ci V8 in favour of offerings with more cubes, Shannon Heraud has history with GM-H’s baby V8, having used and abused them in his ex-burnout Torana sedan.

This article was first published in the September 2019 issue of Street Machine

During the planning stages of the build of his killer Mk1 Escort burnout car (SM, Aug ’18), Shannon was looking for something unusual and affordable to power it. “I had the motor left over when I retired the Torana, so I thought, why not? It just progressed into seeing what we can get out of this little V8.”

What he has ended up with is an amazing piece of street-machining engineering, using plenty of nous to get a killer result for minimal fiscal outlay. “I was given the block years and years ago by my mate Charlie Grieve, who did skids in his Warwick Yellow HK Monaro,” explains Shannon.

The four-bolt bottom end uses a crank that Shannon thinks is from an 80s Holden blue motor, though he can’t remember. “It isn’t anything special, and it hasn’t had anything special done to it,” laughs the Victorian. Scat H-beam forged rods are fixed around the crank with ARP 2000 bolts, while forged JE pistons squeeze a boost-friendly 9.0:1 compression ratio. “To keep it alive, I make sure I do lots of oil changes, and always make sure the engine has oil pressure,” Shannon says.

As part of a recent freshen-up, Shannon went with a new custom-grind bumpstick from Clive Cams. “It’s still a flat-tappet hydraulic cam, and it is in the 250-260-degree range at 0.50, with about 600thou lift,” he says. He also upgraded the rest of the valvetrain to suit. Crane Cams EDM hydraulic lifters to suit a small-block Chev got a run, along with shaft-mount Jesel Sportsman rockers with a high-lift 1.7 ratio, and thicker 3/8-inch Trend pushrods that won’t deflect under the strain of 7000rpm.

“The heads are basic early HQ-style iron red heads that I hand-ported,” Shannon says. “I opened them up in the throats a fair bit, gave them a five-angle job, and machined them out to fit the bigger Isky valve springs.”

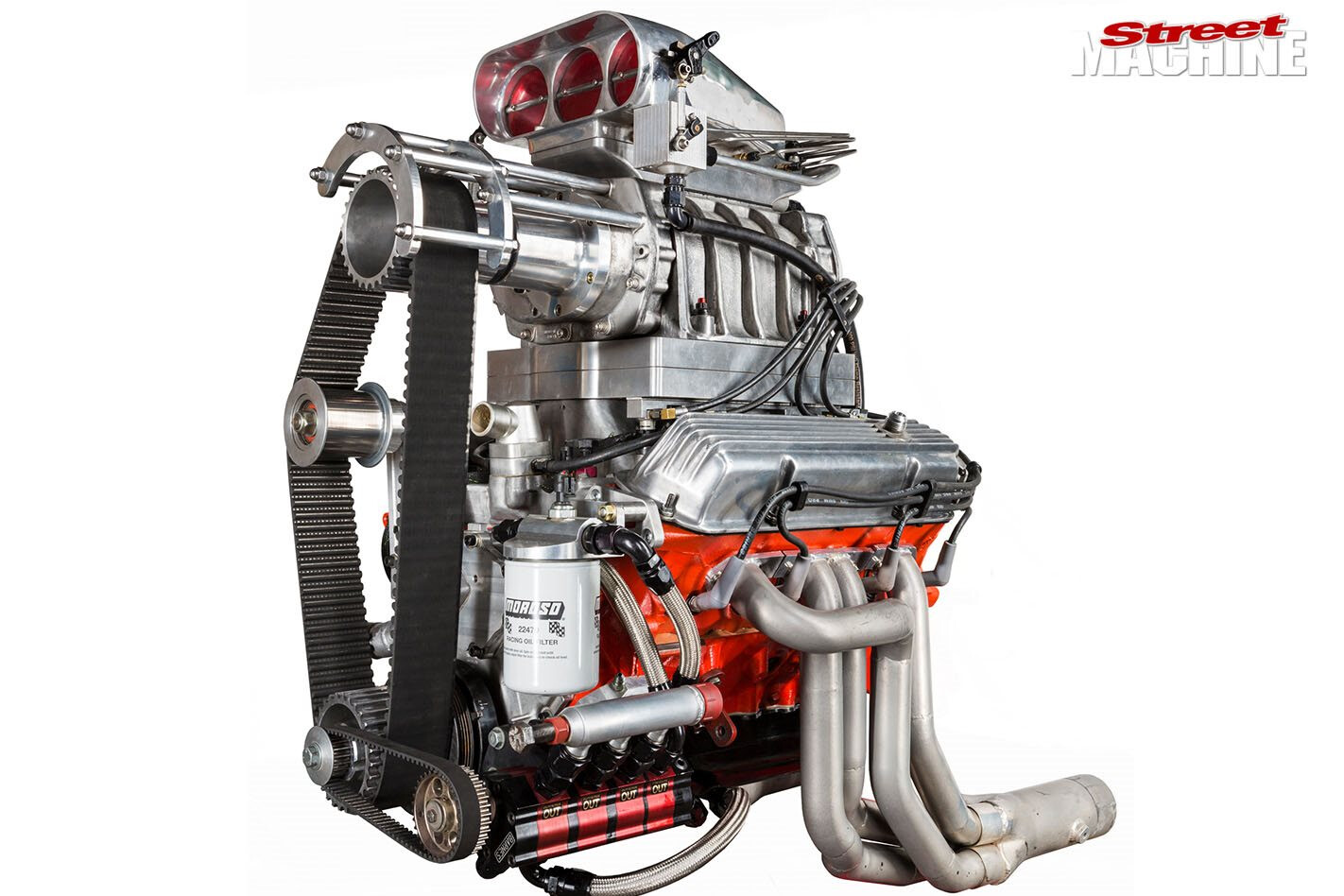

While most of the engine is quite understated, one piece of exotica that stands out is the four-stage Barnes Systems drysump oil pump and custom oil pan sitting on the bottom of the donk.

“I’ve never weighed the Escort, but I think it is around 1150kg,” says Shannon. “I want it to run a nine, but we’ll have to see what tweaks it will need. The converter might flare a bit more, so we might need to look at that now”

“The sump is a custom pan built by an ex-HRT engineer about 20 years ago while he was still working there,” says Shannon. “It was built in a similar style to the Group A dry-sump set-ups.”

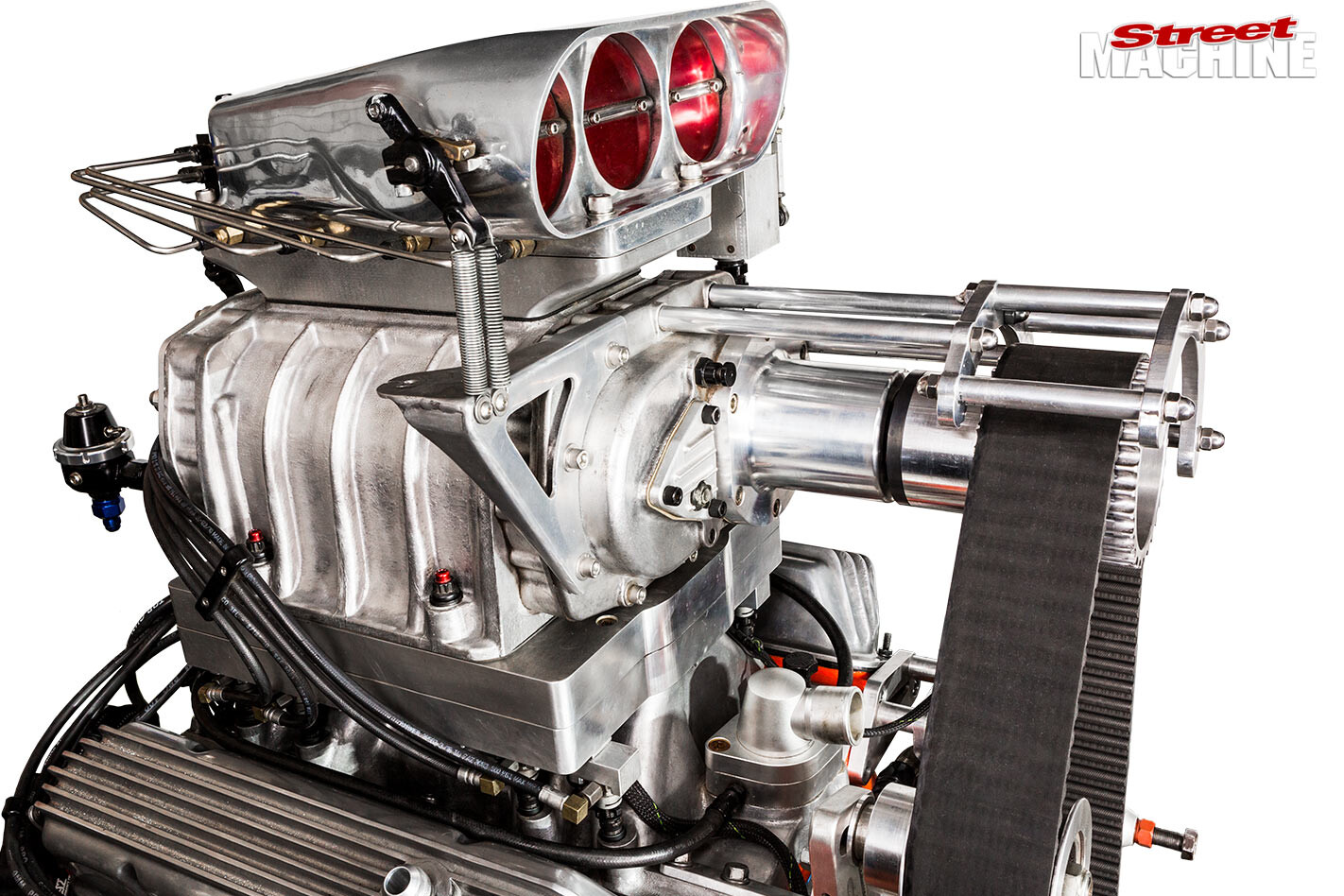

The GM 4 /71 isn’t a blower you’d be used to seeing on a skid car – until Shannon came along and rebuilt his to suit methanol fuel and up to 12psi of party boost. It is mounted on a Redline tunnel ram that Shannon modified to suit by removing the plenum and making his own blower manifold

Under the GM 4/71 blower and Enderle injector hat is an old Redline tunnel-ram intake that Shannon whipped the plenum off and replaced with a unit he custom-made to fit the air pump. At its base are eight Bosch 1000cc injectors feeding straight methanol into the 253, while another two squirters are hidden inside the bug-catcher hat, along with an LS1 throttle position sensor sending info back to the Autronic SM4 ECU.

While it has been painted red like an early Holden V8, the block actually dates from the 1980s, and modifications are limited to adding four-bolt mains. “A lot of the early HT-HG 253s have jumped in value, but you can still pick up the later-model 253 engines cheapish for a few hundred bucks,” Shannon says

For ignition, Shannon uses the SM4 paired to an Autronic 500R CDI box, with a four-point magnetic crank trigger to tell the ECU where the crank is in each cycle. The dizzy is retained to act as a cam sync for full sequential EFI, and to fire the spark from the coil to the leads without the need for ugly individual coil packs.

“The heads still use ARP 7/16in bolts,” Shannon says. “I talked to John Sidney about going up to half-inch head bolts, but he didn’t recommend it. The mains are also ARP, and I used grade-eight bolts in the four-bolt mains”

Spent gasses tumble out of 17/8-inch primary pipes that wind up at 3.5-inch collectors, and were originally fitted to a very famous Victorian burnout car: “The extractors I bought years ago, and they started off on Clint Ogilvie’s FRONT/BACK Torana,” Shannon says.

The specs of Shannon’s 253 might seem basic, but he has made solid investments in key areas, like the Barnes four-stage dry sump system. Guaranteed to keep oil pressure consistent, it fixes a well-known Holden weakness and ensures Shannon doesn’t grenade the bottom end when he’s beating on the motor out on the burnout pad

With the Escort running on pure methanol, there isn’t a huge requirement for a monster radiator, so simplicity rules the day once again. “It is a three-core copper and brass custom radiator, about the size of a VN V8 unit,” says Shannon.

Running 9psi on the John Sidney engine dyno, the Little Thongslapper That Could made 600hp at 7000rpm, with 450ft-lb of torque at 6500rpm, though Shannon plans to eventually step up to 12psi of boost and head for the nine-second bracket. Yep, TUF253 isn’t just a burnout car; it also dabbles in drag racing and skidpan outings, too!

“Fuel is supplied through a –8 fuel line, running dead-head,” says Shannon. The deadhead system is simplicity itself, as it does away with the need for a return line

“I don’t touch the tune at all when I go to the drags,” says Shannon. “I just soften up the rear shocks, chuck the slicks on and go. I have been changing the diff gears of late just trying to find the right combo, as it hooks up well but it needs to 60ft better.

“The 253s seem to rev pretty clean and easy, but I don’t know if that’s a 253 thing. I’ve always played with Holdens and they have done well. I built this engine for reliability, because while we could get more power, the rods are nearing their limit and that factory crank probably needs to go if we were to push the motor harder.

“The valves are the next things I’ll have to upgrade, as they’re nothing special. We might build another motor down the track with some more expensive stuff in it, with bronze lifter bores and maybe a roller cam. But we have a few projects on the go.”

The Enderle hat looks set up for mechanical injection, but Shannon actually runs full sequential EFI in his 253 to allow for more control over ignition and fuelling in the motor. He has also hidden two Bosch 1000cc injectors in the hat to mist methanol onto the supercharger rotor pack below

Shannon thanks John, Mick and Neil from John Sidney Racing and his fiancée Briana Cable for their ongoing support in building one of the world’s angriest thongslappers.

Comments