Since we featured part one of the Little League 253 engine story a few years ago, we’ve been inundated with requests to bring you the end result of the build. Here in part two, we pick up the story with the little 253 getting ready for the dyno…

This article on the Little League 253 was first published in the July/August 1996 issue of Street Machine

With the help of Rick Jones’ Dyno 2 computer program, we predicted a possible 370hp from our little Holden 253, with a full-on – read: slightly impractical – state of tune. But as this engine build is for a street car, we have obviously pulled the reins in a little.

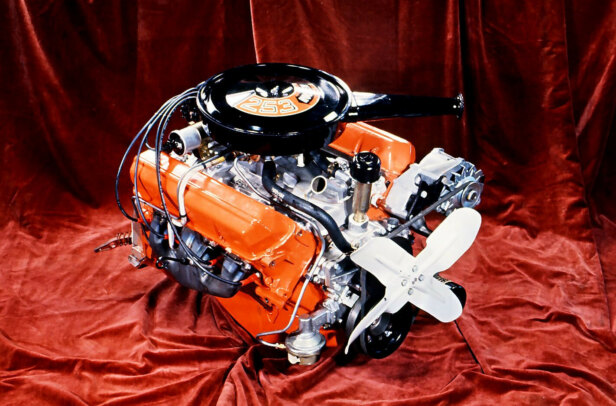

The heads came back from Racing Head Services with the bigger valves and some run-of-the-mill porting, 1.65 Yella Terra roller rockers, Speed Pro springs and chrome-moly pushrods. The engine was assembled using the regular Holden 253 steel shim head gaskets, a stock later-generation electronic Holden distributor and a Holley 600 on an aftermarket intake manifold.

An engine or chassis dyno allows the engine to be set up right first time

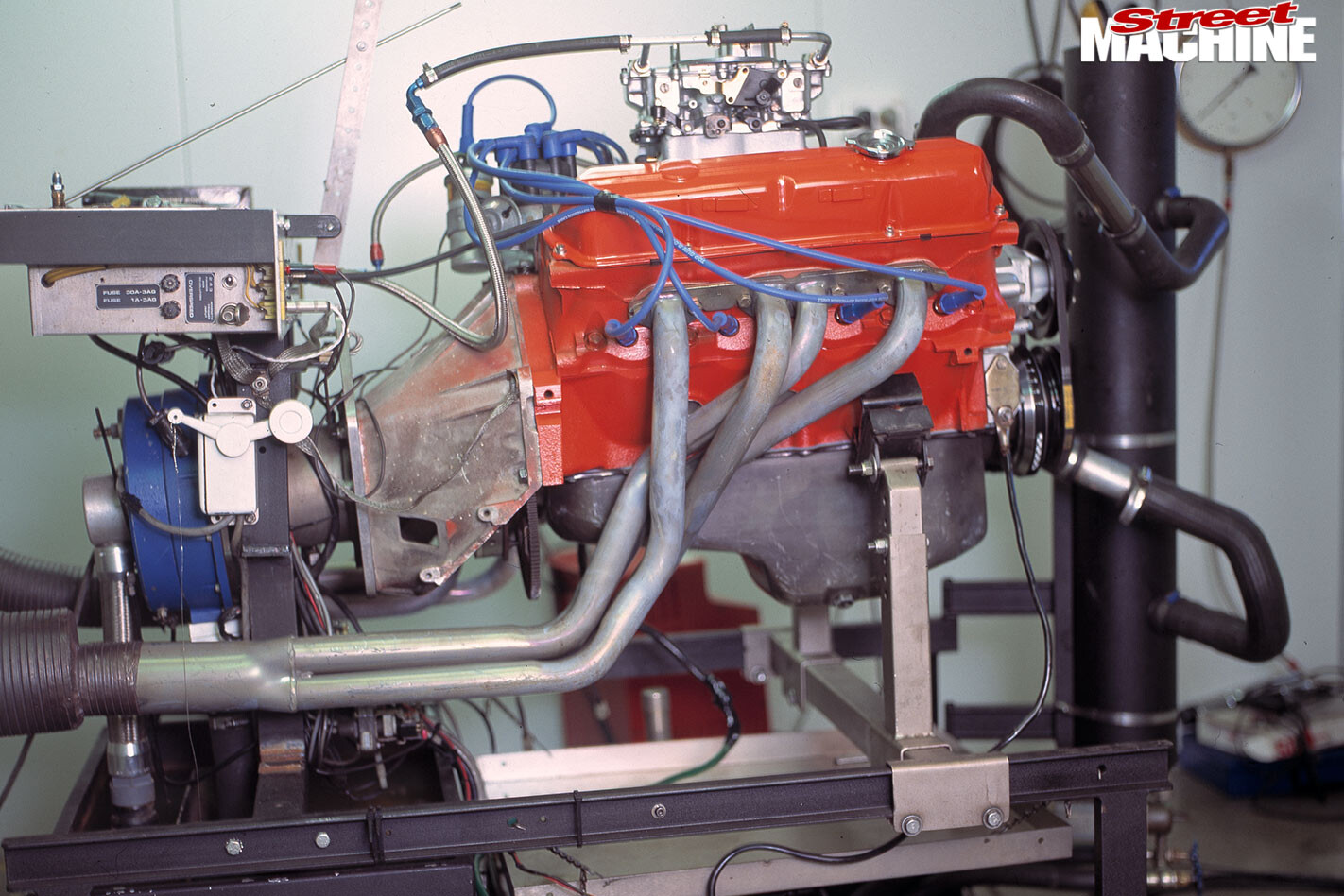

The engine was taken to Hanley Racing Developments in the Sydney suburb of Seven Hills for some dyno time. Running an engine in and sorting the engine tune is a whole lot easier on a dyno than in a car. The expense of a dyno may seem a lot to swallow straight after you’ve dumped a bundle into the engine itself, but believe us when we tell you it enables you to get the engine right, from the beginning, without stuffing around.

After installing the engine on the dyno and priming the oil system, the engine was kicked into life. As Murphy’s Law always prevails when working with all things automotive, we had a problem: a badly leaking inlet manifold which had to be re-machined, costing us half a day of dyno time.

After rectifying and refitting the inlet manifold it was time for some fun. The four-into-one type extractors featured 1½-inch primaries with a three-inch collector. We ran the engine for around 40 minutes under light load to break-in the camshaft and bed the rings to the bores, after which the tappets, timing and oil were checked.

We found 90hp in hours, not the weeks it could have taken ‘seat of the pants’. Stock Holden 308 manifold and Holley delivered 334hp. That’s 250kW

Time to light the cracker! The first run was to 5000rpm. The mixture was lean; the power way down. Only 244hp and 221lb-ft of torque. After setting the carby a bit richer, another run to 5000rpm showed an improvement to 266hp and 244lb-ft. This was obviously better, but still way off the mark. Remember, our computer-calculated predictions were for 336hp at 6500rpm and around 320lb-ft at 4500rpm with this combination. The distributor was re-graphed to give 38 degrees full advance (all in by 3800rpm) on 15 degrees static.

After doing this, and richening it up a little, we decided to run to 6500rpm to see what happened up the top of the revs. At 6300rpm, it made 305hp and 273 lb-ft, but something was not quite right. After checking everything with no result, we fitted a stock HQ 308 four barrel intake manifold (with the plenum roof machined away to suit the Holley) and ran the test again. Much better now: 322hp at 5800rpm and 310lb-ft at 4800rpm. With adjustments to the carb, we found 334hp at 6200rpm and 310lb-ft at 4500rpm.

All the dyno tests were performed using pump petrol with 104 octane booster as a safety measure. Driving to work, pump premium should be adequate but keep an eye on brand and quality. For getting stuck into it – like at a street meet drag night – drop some booster into the tank.

The engine was plonked into a manual VK Commodore with a 3.45 diff, Genie headers and exhaust. It’s bloody nice to drive and pulls like crazy all the way to 7000rpm.

It idles at 950rpm and sounds tough. An auto with this engine would need a hi-stall convertor (around 3000rpm) and the 3.45:1 diff gears are easily installed by fitting a VL Commodore rear axle. In a light car this would be potent street and strip special: this engine silenced several skeptics in its first week.

On the strip, this Little League 253ci Holden V8 laid down solid 14-second passes (at the old Eastern Creek quarter).

There it is! What is often considered a little orphan Annie engine can be made to punch out some very respectable numbers – near as dammit to 250kW from 4.2 litres.

LEAGUE OF HER OWN

While our Little League 253 donk was dropped into a VK Commy at the end of its original build, the engine was eventually sold off to Danielle Freeman who plugged the cubically challenged screamer into her bright pink EH sedan (Iron Maiden, Mar ’97). Dani painted the engine block grey and dressed up the 334hp bent eight with a pile of chrome parts, a polished intake and some fenderwell headers. Using steeper gears than the Commodore (3.7 vs. 3.45) and a 3-speed auto trans we reckon that the lighter-bodied EH was easily capable of delivering high 13sec quarters. Not bad for a junkyard reject!

FINAL SPECS

• 261ci from 60-thou overbore

• 10.5:1 compression

• 238 degree (at 50 thou), 0.500 lift cam on 106 degree centres

• 1.85 intake valves, 1.50 exhausts

• Genie headers and exhaust

• Power: 334hp at 6200rpm (249kW).

• Torque: 310lb-ft at 4500rpm (421Nm)

Comments