Inspired by Carroll Shelby’s 200mph racers, this carbonfibre Daytona is one exotic street car

This article on Graeme Beaupeurt’s Daytona was originally published in the 2014 issue of Street Machine’s LSX Tuner magazine

VICTORIAN company Daytona Sports Cars was built on a racing legacy. Back in the mid-60s, Carroll Shelby’s Cobras monstered short-course racing, but they were blown away at high-speed tracks by svelte European coupes. To rectify matters, Shelby brought in Bob Negstad and legendary US car designer Peter Brock.

The Daytona’s distinctive Kamm tail was a signature of many GT race cars of the 1960s. Named after 1930s German aero ace Wunibald Kamm, the design features a smooth body with an abruptly cut off tail. Early developmental cars suffered at high speeds until Phil Remington added the duck-tail spoiler for additional downforce

Negstad built a new chassis and suspension system, while Brock turned the Cobra’s AC roadster body into a streamlined coupe.

The 300km/h monster was named Daytona (after the then-new super-speedway) and went on to achieve a distinguished career in only two years of racing, including the Daytona 24-Hour in ’64 and the FIA World Sportscar Championship in ’65.

With the Daytona project dumped by Ford in favour of the GT40, in November 1965 Shelby took the prototype Daytona (#CSX2287) to the Bonneville salt flats. Craig Breedlove, Bobby Tatroe and Tom Greatorex set 25 USAC/FIA speed records

Shelby only built six Daytonas in 1964-65 before Ford moved onto the GT40 project, and so the Daytona legend died off for 30 years. It was brought back to life in the 1990s when interest in re-creation and ‘tribute’ cars started to rise again. Which is where Daytona Sports Cars (DSC) comes in.

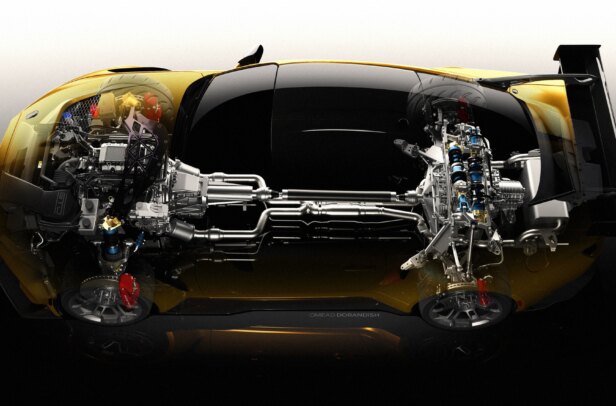

Built on a custom spaceframe chassis by well-known race-car constructor Borland Racing Developments, their early cars used SS Commodore drivetrains, brakes, wheels, diffs, steering column and controls, as well as traction control and ABS.

“We have done a few carbonfibre-bodied cars, but there is quite a bit more work in the lay-up when the carbon is to be clear-coated,” James says. “It would probably take some serious arm-twisting for us to do it again”

Lately, however, James Bendell and the boys at DSC have been fitting 427-cube LS7 engines – far more in keeping with Shelby’s original intent for the car.

And then you have guys like Graeme Beaupeurt, who went even further by having James and DSC build a featherweight full-carbon Daytona for him.

“Graeme has another Daytona coupe that he uses for track days and tarmac rallies,” says James. “After a small ‘incident’ in that car he decided he needed another one that would not see the abuse of racing.

“Basically, we had the chassis and suspension arms made by Borland racing, and the rest was done in-house. Graeme settled on a specification for the car with us, choosing the LS7, Holinger ’box, MoTeC ECU, the colour, carbon body and the like, and we built it for him.

“When building his first car we had it engineered and organised the registration but, for this car, he took on that job himself.”

Rather than putting up with the LS7’s paltry standard output of 505hp, Graeme decided to jump in and open up the track-oriented motor. He added Mahle pistons and ACL bearings to the standard titanium conrods, and replaced the standard oil system with a proper race-style ARE four-stage dry sump.

Graeme’s car is a big-dollar set-up, from the LS7 motor and Holinger right down to the mega-buck MoTeC M800 ECU, which controls the Bosch 044 fuel pump and injectors

Ferrea stainless exhaust valves have been added to the stock Del West titanium inlet valves in the big-port CNC LS7 heads. And as he wanted this motor to rev like a two-stroke, Graeme also fitted Trend pushrods, Crow springs and ARP head bolts.

He needed those modifications to suit the deep-breathing Harrop Hurricane individual throttle-body inlet manifold and lumpy Crow cam.

Even though LS7s have been known to handle 8000rpm out of the crate, Graeme has safeguarded his with an upgraded Katech timing chain and LS9 tensioner, plus an ATI harmonic balancer.

Behind the seven-litre fire-breather sits a real piece of Aussie race engineering royalty – a full-tilt Holinger sequential transmission. Graeme’s RD6-S unit is a lightweight, small-case six-speed sequential manual, similar to units found in V8 Supercars or Le Mans 24-Hour race cars.

The Holinger’s dog gears allow him to bang through shifts with just a slight lift off the throttle on up-shifts, making for brutally fast acceleration.

It feeds power back to the Hardy Spicer single-piece tailshaft and a Daytona diff packing a Mark Williams LSD and Richmond 3.08:1 final drive.

Given the Daytona’s mantra of bulk speed and minimal weight, the cabin isn’t overflowing with luxuries. However, it’s still a damn nice place to be thanks to retrimmed Velo GTP2 seats with Daytona Sports Car branding, a Sparco tiller, full rollcage, MoTeC dash unit and Holinger shifter

The power and violent acceleration is kept in control by the steam-roller 18×10 and 18×12 Simmons FR18s wrapped in super-sticky Pirelli rubber. The stoppers are Harrop 380mm discs and six-pot calipers up front, with 356mm discs and four-pot rears to suit, matched with the OE Holden master cylinder and ABS set-up carried over.

They’re held up by German Eibach springs and Koni shocks, with a Holden rack-and-pinion steering set-up pointing the way. Because of the performance potential and race-style frame, there are no rubber chassis or suspension bushes in the Daytona, which instead rocks solid spherical metal bearings.

“Graeme’s car is unique in that it is the only car with exposed carbon for its GT stripes,” explains James. “The composite work was done by Richard Struthers of Cobrax, who works from our factory and has made all of our moulds and all composite parts.”

The PPG Sting Red (a modern Holden colour) was laid down by Daytona Sports Cars’ John Hebblethwaite over the vacuum-infused carbonfibre body. It was then down to James and John to piece the big puzzle together, only farming out the wiring and trim.

“The trim was done by our usual trimmer, David McBride of McBride Auto Upholstery, and the wiring was by Chris Fahey of Prestige Auto Wiring, who has wired all our cars,” James says.

The finished product is a testament to how one Aussie company took a classic American race car and turned it into a hand-built street-brawling supercar. The big question is: which Daytona would you pick if you had both in your shed?

GRAEME BEUPEURT

2012 DAYTONA SPORTS CAR

ENGINE

Type: LS7 427ci

Inlet: Harrop Hurricane ITB

Pistons: Mahle

Cam: Crow

ECU: MoTeC M800

Oil system: ARE dry sump

Exhaust: Daytona headers, twin 2¼in pipes, Lukey mufflers

BENEATH

Box: Holinger RD6-S sequential

Tailshaft: Hardy Spicer single-piece

Diff: Daytona case, 12-bolt Chev, Richmond 3.08 gears, Mark Williams LSD

Struts: Eibach springs, Koni dampers

Brakes: Harrop six-spot (f), Harrop four-spot (r)

ROLL

Rims: Simmons FR; 18×10 (f), 18×12 (r)

Rubber: Pirelli P Zero Rosso; 275/35 (f), Pirelli P Zero Rosso; 315/35 (r)

Comments