GEORGE Poteet and his Speed Demon streamliner set the land speed racing world on fire at this year’s Southern California Timing Association (SCTA) Speed Week, becoming the world’s fastest piston-powered vehicle on land with a two-way average of 470.016mph (756km/h).

This article was first published in the November 2020 issue of Street Machine

In doing so, he broke the two-way, top-speed, wheel-driven internal combustion engine mark of 448.757mph set in 2018 by Danny Thompson in his refurbished 50-year-old Challenger II, which ran two normally aspirated nitro-fuelled Chrysler Hemis.

As cool as that accolade was, what Poteet and his team were really interested in was adding to their collection of SCTA blown fuel streamliner class records. Going into Speed Week, the team already held six records using a variety of engines, including small-block Chev, LS-based, a four-cylinder Dodge and a Ford flathead.

The missing record was AA/BFS, which mandates a 501ci or larger engine (or engines), which the team had never run. That’s big-block territory. The record had been stuck at 417mph since 2004 when it was last set by Tom Burkland’s all-wheel-drive streamliner running two supercharged Generation II Chrysler Hemis on alcohol.

Poteet’s solution was a 3155hp, Ken Duttweiler-built, electronically managed, twin-turbo 557ci big-block Chevy. Let’s check it out!

GO BIG OR GO HOME

ENGINE builder Ken Duttweiler had avoided using a big-block Chev ‘rat’ motor in Speed Demon in the past. “We didn’t think a big-block Chevy would fit between the Speed Demon’s narrow frame-rail width,” he says. But these days, conventional asymmetrical intake-port Dart big-block heads are good enough to support the kind of boosted airflow necessary to do the job, making extreme, tall-runner, symmetrical-port Big Chief Pro Stock-level heads no longer necessary.

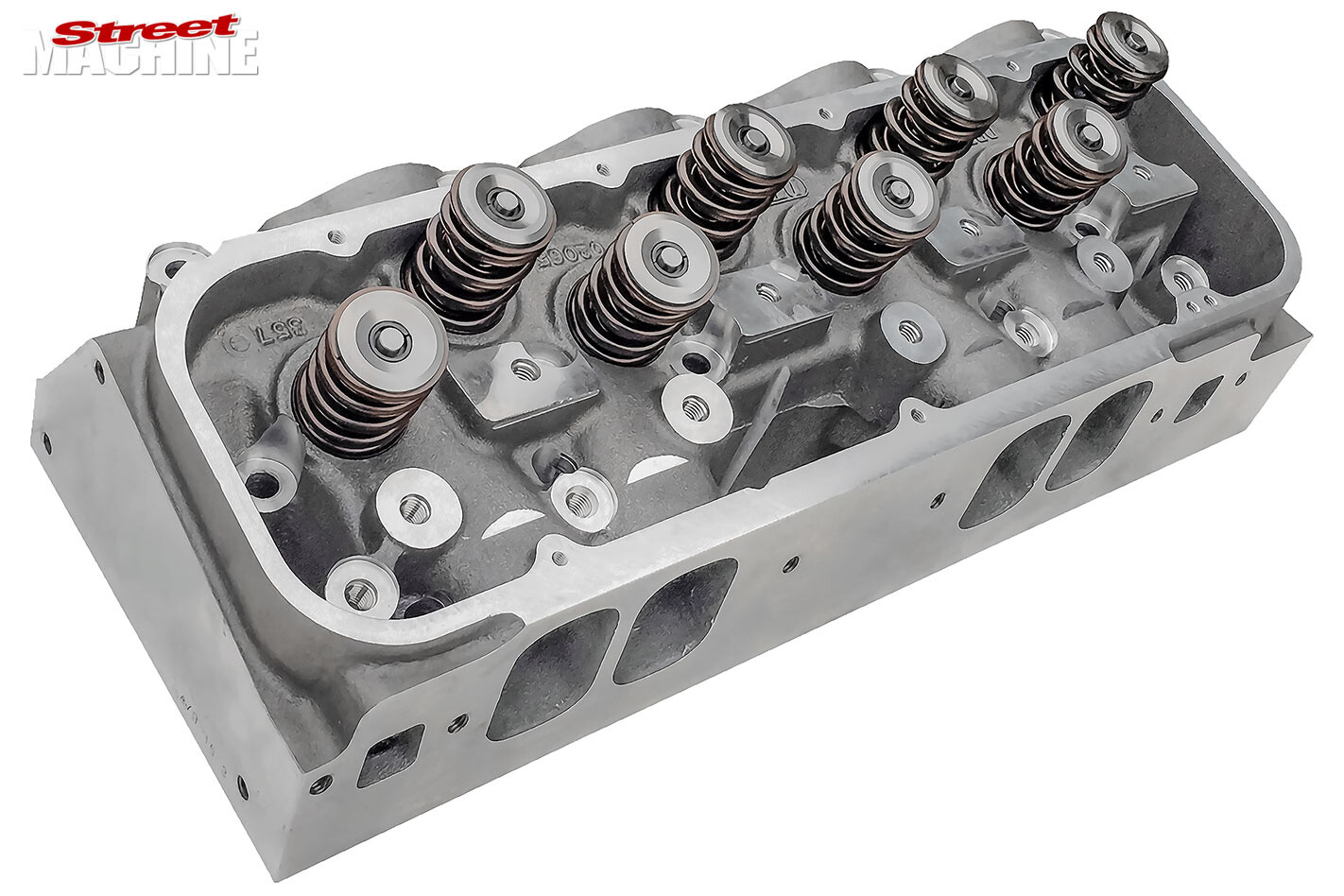

Dart’s PRO1 20° cast-aluminium heads are intended for large-displacement rat motors running 8000rpm or higher in NA, nitrous or big boost applications. The intake ports retain an asymmetrical rectangular profile, but the 0.500in raised port entrances measure 2.600in tall by 1.850in wide. The 451cc, CNC-ported intake runner volume is the largest in the PRO1 series. Photo: Dart

With lower-profile heads, the big-block mill was able to squeeze between Speed Demon’s existing frame rails and bolt up to the front engine-mounting plate. However, a BBC is one inch longer than a traditional small-block, so the crew moved the Liberty seven-speed trans back to make room for it. If the team elects to tune up some of the lower-class small-block records it already owns, the smaller-displacement small-block Chev and LS engines in the team’s arsenal can fit the revised layout by adding a rear spacer plate.

With the body panels removed, this is the new big-block installed in Speed Demon. It’s so clean, it reminds one of classic piston-engined World War II liquid-cooled fighter aircraft. Well, except for the modern electronic controls. Note the rear-facing throttlebody inlet. Not an inch of wasted space here

CYLINDER BLOCK

DART’S Big M iron blocks use billet-steel, four-bolt main caps with splayed outer bolts, and feature the Gen VI big-block’s 0.300in-taller lifter bores. Duttweiler is using the standard Chevy passenger-car deck-height block delivered with 4.560in bores (which Duttweiler finished to 4.565). Production side-engine mount provisions, a mechanical fuel pump boss and a standard Chevy oil filter mount come standard on these blocks, but Duttweiler specified some additional options: He had Dart machine all the cam journals to 55mm, the same as modern LS engines (stock big-block cam journals range from 53.848mm to 54.356mm). “I like the big LS journals,” he says. “We can have a little larger cam base circle, making for a more rigid billet cam even with extreme lobe lifts.”

Visible in the valley are the oversized bushed lifter bores that accept Jesel keyed lifters, and an anti-debris plate installed by Duttweiler over the oil drain-back slots that prevents any upper-end parts failures from falling into the rotating assembly

For greater strength, Duttweiler special-ordered the block with Dart’s $2000-extra, compacted graphite iron (CGI) alloy block-casting option. Recommended for turbocharged, supercharged and nitrous oxide applications, this alloy doubles the casting’s strength compared to conventional iron blocks, without adding weight.

The engine is based around a Dart Big M Mark IV iron block with siamesed cylinder walls, available from Dart in two different deck heights (passenger-car 9.800in or the raised ‘truck’-style’s 10.200in). As-delivered bore sizes range from 4.25in all the way up to 4.600in. Photo: Dart

ROTATING ASSEMBLY

RIGIDITY and dependability are paramount for triumphing at Bonneville. Rotating weight is not as critical as structural integrity when an engine needs to make thousands of horsepower but has five miles to get there.

Dart’s Big M blocks come with extra lifter-valley head-stud bosses (arrows), which help head gasket retention. But Duttweiler also machined the block and heads with receiver grooves around each cylinder for Visner Flame Hoops, then installed the heads using ARP Custom Age 625+ head studs that take higher torque for greater clamping force

For the crankshaft, Duttweiler says a four-inch stroke (which yields a 524ci engine with the 4.565in bore) would have been sufficient, but as it turned out, Callies had a 4.25in billet-steel crank just about ready to go. With the bigger arm, the engine displacement topped out at 556.5ci. “We don’t have to rpm really high – not over 9000 – so that extra quarter-inch stroke is not a real liability here,” Ken explains.

“To get the weight we wanted and add strength, Auto Verdi thickened up the conrod,” Duttweiler says. “With ARP Custom Age 625+ capscrews – 290,000psi tensile strength – we could get the clamp load we needed with 7/16in rod bolts instead of going with larger, heavier half-inch bolts”

Duttweiler generally specs thicker, heavier conrods to withstand the prolonged stress of high-boost racing for five miles at a clip. For this motor, Ken went offshore to Sweden’s Auto Verdi Racing, which has recently been making a name for itself in NHRA Pro Stock. Auto Verdi forges its rods in-house out of Swedish chrome-nickel molybdenum steel, and uses the latest CNC machine tech. Verdi’s H-profile conrods are available in virtually any length, bearing size and pin size, custom-made for each customer.

The engine’s rotating assembly includes a Callies crank, Auto Verdi connecting rods, Diamond pistons, Total Seal rings and ARP Custom Age 625+ fasteners to hold it all together. Note the Dart block’s billet four-bolt main caps with splayed outer bolts and multi-pattern oil pan mounting holes

“Verdi offered to make any rod we wanted,” Duttweiler says. “I knew 930 grams was about the right weight for reliability, and 6.400in centre-to-centre was the length needed with the piston and ring pack I wanted to use in a 9.8in deck-height block. No problem for them – 30 days later, we had 10 rods, including two spares.”

The Diamond pistons specced by Duttweiler are strong and thick enough to handle prolonged boost, with a deep dish that develops around 9.3:1 compression on the boosted, methanol-fuelled engine. The beefy H-13 tool-steel, 0.990in outer-diameter big-block Chev pins have extra-thick 0.250in walls and a DLC (diamond-like carbon) anti-friction/anti-wear coating

The rods swing Diamond deep-dish pistons forged from boost-friendly 2618 aluminium alloy. Diamond’s pistons and unbendable, thick-wall H-13 tool-steel pins are based on a turbo-friendly configuration Duttweiler has used in his small-block and LS mills.

Total Seal supplied the piston rings, and both crank and rods ride on coated and chamfered Clevite racing bearings. “I believe in coated bearings,” Ken says. “Coating eliminates roughness, and we see better wear characteristics.”

Big-block Chevy shaft-mount systems usually have separate intake and exhaust rocker stands, but Jesel made this one-piece, big-block shaft-mount rocker stand that ties the intake and exhaust together to better spread the load

CAM & VALVETRAIN

SPINNING in Dura-Bond cam bearings, the custom Comp Cams mechanical roller cam has 280/296 degrees intake/exhaust duration at 0.050in tappet lift, with a total lift of 0.850in at the valve. It’s ground on a wide 115-degree lobe separation angle (LSA) and installed straight up. “The wide LSA shortens the combustion time in degrees by closing the intake valve a little later,” Ken says. “This helps prevent detonation. On a turbo engine, we keep the overlap down yet still make good power, because it keeps exhaust from blowing up the intake runner.” The other benefit from a wide LSA and reduced overlap is scads of piston-to-valve clearance. “We easily have 0.200in-plus clearance on both intake and exhaust.”

Comp Cams ground Duttweiler’s custom mechanical roller cam from tool-steel billet. “Tool steel is more wear-resistant, thanks to one-pass machining that results in the same hardness all the way through,” Duttweiler says. “With normal alloys, you often will see a lifter-roller mark on a used lobe. Not with these billets!”

The exhaust lobe profile is one of Comp’s new Top Fuel cam designs. “There’s more cylinder pressure on the opening side of the exhaust valve than normal,” explains Duttweiler. “It wants to pull the exhaust rocker stand mounting studs out of the head. So we figured, why don’t we slightly decrease cylinder pressure by slowing the exhaust valve opening point a few crank degrees?”

Speed Demon’s Callies Ultra Billet crank is made from from low-carbon, high-nickel steel. Multiple heat treatments result in a crank with fracture-resisting ductility, stiffness and a wear-resistant outer case. An extra centre counterweight on each side of the #3 centre main-bearing journal makes the crank more stable

The cam lobe order is for a 4/7 firing order swap. Traditional Chevy V8s use a 1-8-4-3-6-5-7-2 firing order; with a 4/7 swap, the order becomes 1-8-7-3-6-5-4-2. The swap is claimed to decrease crankshaft deflection, deliver a smoother torque curve, aid acceleration and maybe even deliver a few more horsepower.

Keyed Jesel lifters better resist rotation compared to link-bar-type lifters. The lifters on this motor have a larger 0.937in body (stock GM is 0.842), which allows a bigger roller wheel to better spread the load, reducing wear by rotating more slowly

CYLINDER HEADS

STOCK big-block Chevys have a 23-degree valve angle, but the Dart PRO1 20 heads installed on this motor have a valve angle of 20 degrees. This allows a shallower piston valve relief, smaller combustion chambers that develop high compression with minimal piston domes in NA usage, and an improved short-turn radius to the valve bowl.

Duttweiler says the Dart heads are ready to go out of the box. Even the valve job comes finished on the 55-degree seats, a seat angle specified for their reputedly superior high-lift flow. Duttweiler’s set uses beryllium seats on both intake and exhaust; bronze wall guides are used with the titanium intake valves, but due to extreme heat the exhaust seats are steel with a bronze insert.

Duttweiler specced 11/32in-stem Ferrea valves: lightweight, 6.030in-long, 2.40in outer-diameter titanium intake valves, and high-temp-resistant, 5.930in-long, 1.800in outer-diameter Inconel exhaust valves

Head gasket sealing has not been a problem. Duttweiler has perfected sealing with SCE copper head gaskets and unique Visner Flame Hoops. The finishing touch is high-alloy ARP Custom Age 625+ 7/16in head studs. Custom Age 625+ is an extremely high-

tensile alloy that’s way beyond even ARP 2000. ARP supplied all critical fasteners on this engine.

A larger-diameter lifter body provides room to offset the pushrod seat, improving the pushrod angle on canted-valve big-block Chevy heads. Getting the angles right on this build required four offset intake-side lifters: two with a 0.180in offset and two with an 0.080in offset; the exhaust-side lifters are all on-centre

OILING

DART’S block uses a priority-main oil system: The mains and rods get fed oil first, and subsequently (through restrictors) the cam, upper end and valvetrain. A Dailey seven-stage dry-sump system circulates Lucas 20W-50 full-synthetic or special thick 50W-Plus semi-synthetic oil specifically blended for alcohol-burning engines. “I’m very happy with Lucas,” says a satisfied Duttweiler. “We’ve been using their products for 15 years.” Oiling has just not been a problem on the big rat motor.

Getting 13.25L of oil into and out of the engine at over 90psi is the responsibility of a Dailey Engineering dry-sump oil pan and attached pump with six scavenge stages, one pressure stage and an oil-air separator component that’s done wonders for suppressing any oil-foaming tendencies

AIR, FUEL, SPARK, ICE

ALL of Speed Demon’s engines, regardless of displacement, run the same Precision turbos, which assists with quick engine swaps and tuning. Currently, they’re twin off-the-shelf Precision Turbo GEN2.2 Pro Mod 88s. The turbos’ one-piece centre housing and ompressor backplate assembly is an aluminium forging; the stainless-steel turbine housing has an extended turbine discharge with cross-bolt provisions for added safety. Dual ceramic ball bearings support the rotating assembly.

Duttweiler uses Total Seal oil rings. “Oil control in the cylinders is critical for suppressing detonation, so we used a heavy-tension oil ring, a Napier second compression ring and a gapless top compression ring.” Piston gas-porting helps better load the top ring against the cylinder wall

A new tube-and-fin intercooler core significantly reduces pressure drop over the traditional block-and-plate-type cores used previously. “The pressure drop at 40psi through the new core is now less than 1psi, compared to as much as 2-4psi through the traditional core,” Demon streamliner fabricator Steve Watt explains. The core, intercooler tanks and inlets and outlets now bolt together, sealed by O-rings.

Duttweiler throws 75 litres of water and ice into the intercooler feed-tank per five-mile-long pass. Each pass melts about 36kg of ice.

The Speed Demon team has replaced its old conventional welded-together intercooler assembly (A) with a new modular, bolt-together assembly (B, below)

Another innovation is the custom-made Visner billet oval-shaped throttlebody and hump-roof billet intake, its shape and airflow characteristics similar to the highly effective giant air scoops used on Pro Mod cars. Dave Visner explains: “A normal round throttlebody opening directs more air to the bottom of the plenum, leading to unequal pressure in the plenum.

By going to an oval-shaped throttlebody and 20-degree down-angle in the plenum entry, air pressure and distribution in the plenum is equalised. The plenum configuration acts like a shock absorber to more evenly pressurise the overall volume of air in the plenum, which means more even distribution into all the cylinders front to rear.”

Each intake runner has two Siemens fuel injectors that at the system’s 70psi fuel pressure flow 250lb/h each (for a total of 500lb/h) at an 85-90 per cent duty cycle. The slim-bodied, EV1-type injectors provide sufficient clearance for a canted, side-by-side runner installation that establishes the ideal squirt angle toward the valve’s backside, yet additionally accommodate a third, mechanical-type Enderle injector that comes in at high boost.

If there’s a problem, the team can quickly swap out the core for a spare. The core itself is a new tube-and-fin design (C) with considerably less pressure drop than the previous design

MoTeC’s M150 ECU manages fuel, spark, timing, traction, the cooling fans (for both engine and differential) and boost levels using its fault-tolerant intelligent relays and race-grade sensors. Wheel-slip sensors modulate the amount of boost to prevent traction loss.

Ignition timing at peak boost is 17 degrees; plug gap on the non-projected-tip ice-cold racing sparkplugs (Champion 55 range or Bosch equivalent) is just 0.012in.

The huge 2300cfm Visner throttlebody feeds a three-piece Visner billet CNC-machined humpback intake manifold. The oval-shaped throttlebody and humpback roof configuration equalises air distribution and pressure within the plenum chamber

Exiting the combustion chamber, the exhaust gases travel through Steve Watt-built stainless-steel headers with 2.25in primaries dumping into 3.5in collectors.

There are three injectors per cylinder: two Siemens EV1 mini EFI units (A) plus one Enderle mechanical injector (B). “When we get to 2300-2500hp, we turn on the mechanical nozzle,” Duttweiler explains. “The ECU actuates the Enderles through a large Nitrous Supply high-flow fuel solenoid”

ON THE DYNO

WITH a modest 35psi of boost, the engine churns out 3155.6hp at only 8300rpm, with 1826.5 average horsepower between 5100 and 8300rpm. Duttweiler says that on a 557ci engine, “14-15psi of boost is 1600hp; 17psi is just under 2000hp. It will do everything we need to do at 20psi or 2000-2100hp.” That’s easily enough to go 470mph without abusing the engine under average track conditions.

Duttweiler explains: “Boost is what destroys motors, but this engine is reliable to 3500+hp. If we did turn up the boost up to 36psi – which is over 3000hp – we should run 480-490mph, if the track (and traction) allows it.”

The Aussie-made MoTeC M150 ECU drives two M&W Pro-Drag8 high-energy microprocessor CDI boxes that alternately juice eight MSD high-output coils, one for each cylinder. Photo: MSD

The 2017lb-ft torque peak occurs at 8100rpm, just 100hp lower than the power peak. Average torque output is 1388.4lb-ft between 5100 and 8300rpm. This might seem downright unnatural compared to the engines most of us routinely deal with, but Duttweiler must electronically rein in low-end torque via drivetrain management. The engine really isn’t fully unleashed until it gets over 7000rpm in high gear. “We can’t have too much torque too early in the run, or it will never get traction,” Ken says.

FULL SPEED AHEAD

IT MAY seem crazy that it has taken 73 years of on-and-off land speed racing competition to get to the point where the 500mph mark for a piston-powered, wheel-driven vehicle may now be within reach, but such is the nature of this endeavour.

Land speed racing is one of the last bastions of amateur motorsport, where hot rodders like George Poteet can still make history. With the twin-turbo BBC-powered Speed Demon’s latest record of 470.016mph, Poteet and his team have once again thrown down the gauntlet for their fellow speed chasers to pick up.

Comments