How much power can you wring out of what looks like a standard LS? Mark Busscher decided to find out and we went along for the ride

EVERYBODY wants more power on the street. Nobody wants hassles from LEOs. Happily, Mark Busscher from MB Performance Competition Engines sussed out the solution to this dichotomy. It’s a stout street motor that looks standard – but isn’t.

The vehicle in question is a Holden Adventra, which came stock with an LS. So Mark found an LS3 block that didn’t seem to have done much work. In the past he’d made 758hp with a similar combination; however this block was topped with a Holley Hi-Ram. Very pretty, but definitely not standard-looking. The question was, what grunt would be possible with a standard manifold hogged out to the limit?

Mark figured that if he could coax 700hp out of the package, he’d buy the drinks. Alas, it was a dry event. The final figures were 641hp@6400rpm and 586lb-ft@4900rpm. Still, that was respectable for a street engine that looked virtually standard. What’s more, the combination turned out 569lb-ft@4000rpm, and that figure didn’t drop until 5700rpm. Even as low as 3000rpm in an earlier run, torque was 525lb-ft. Average figures across the measured band were 605hp and 568lb-ft. Very stout for fetching milk, and also not bad for towing your boat.

So what’s in the combo? Read on!

JUST BORING

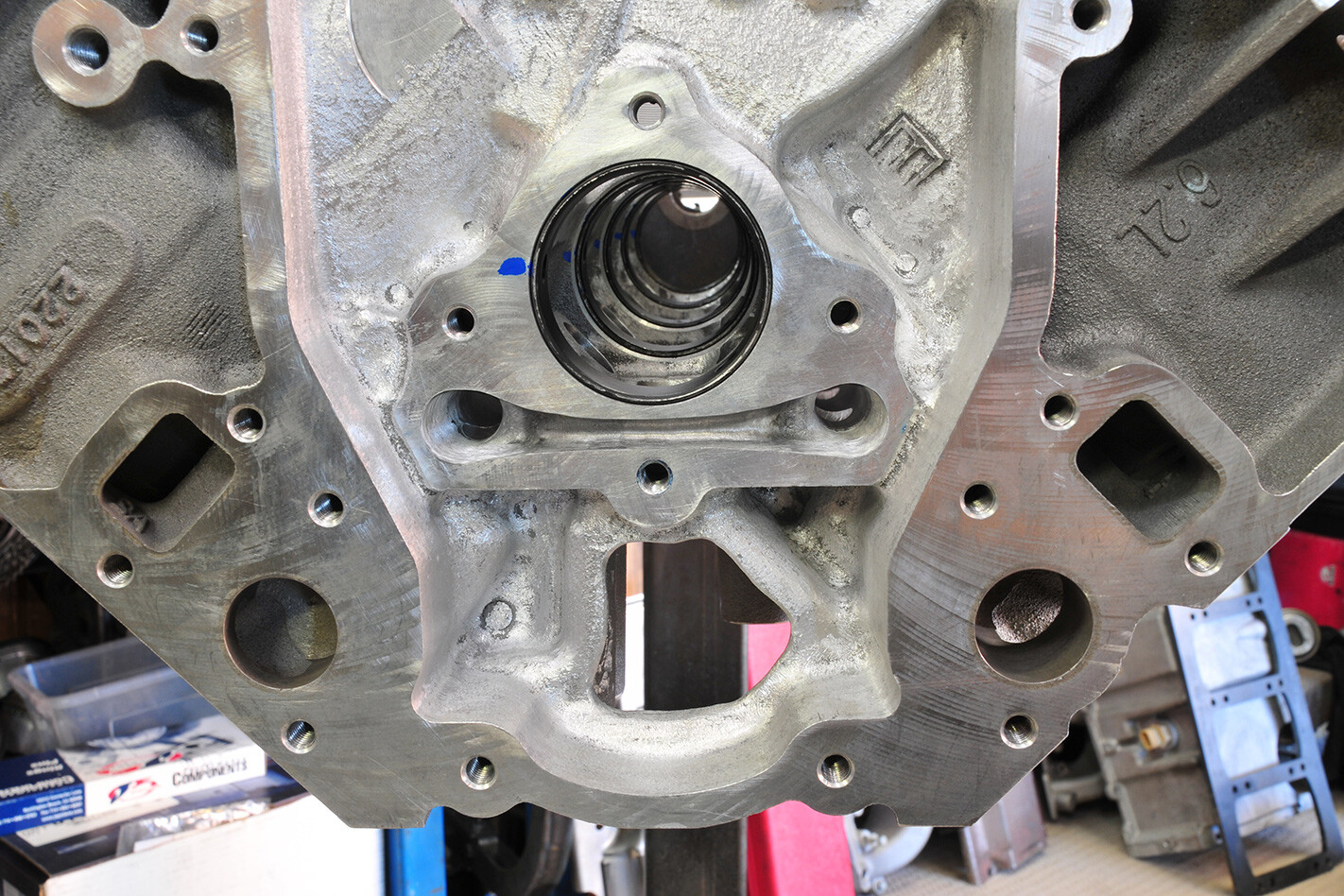

The bores were opened out to 4.075in and coupled with a stroke of 4.0in for a displacement of 417ci, which is an increase of about 11 per cent over the standard 376ci for

this engine. Both crank and rods are from the Lunati Pro Billet series. Mark considers the crank to be the best ever produced by the company. It’s 4340 and made in the US rather than offshore. Reliability is key, and this combination is tried and tested. Which leads us to preparation.

Mark likes to hot-hone his blocks. This means circulating heated coolant through the block to simulate working temperatures. As with any high-quality build, a torque plate is bolted on for the job, but Mark made a thicker-than-standard version that’s particularly rigid. He considers the duplication of working conditions so important that he honed the block with almost everything bolted on: engine mounts, alternator and sump.

Obviously the main bearing caps were also bolted in for the hone, but the surprising thing about them is that they’re standard. Mark’s not concerned – he’s built twin-turbo engines with standard caps that have turned out 1000hp. Recalling the good ol’ days of the 80s, he adds: “We used to get 300 to 400 passes out of a four-bolt 010 block with 15:1 on methanol.”

SOFT ON BEARINGS

Bearings are a different matter. In Mark’s opinion, many bearings, even dedicated performance types, are too hard. He likes ‘Babbitt’ types that are much softer than both factory and general performance units. However, a softer cradle is not enough. Mark also gets his bearings coated by US company Calico. This makes them tougher on the surface while retaining their overall softness. As you’d expect, an ARP stud kit holds the bottom end together.

Conrods are Lunati Pro Light billet 6.125in I-beam units with Honda-sized big-ends. The advantage of Honda journals is that the length of the bearing surface is reduced, resulting in less heat for a given number of revolutions. The throws on the crankshaft are also lighter because of the smaller diameter.

Location of the rods on the journals is not by means of side clearances at the big ends, but rather by side clearances between the small ends and the insides of the pin bosses in the JE pistons. They feature asymmetrical bore faces. At less than 500g, they’re also light.

The heads are standard factory units, modified substantially. Mark considers CNC-ported heads to be a good starting point, but prefers to finish by hand. “Airspeed is everything, so it’s important not to make them too big or it drops off,” he cautions. The inlets flow 380cfm and the exhausts pass about 71 per cent of that – 270cfm. In factory trim, inlets flow about 320cfm. The ports are smaller than standard because Mark fills them up, but the improvement is more due to shape than size. The JB Weld material you can see is for reshaping to enhance swirl.

The heads are standard factory units, modified substantially. Mark considers CNC-ported heads to be a good starting point, but prefers to finish by hand. “Airspeed is everything, so it’s important not to make them too big or it drops off,” he cautions. The inlets flow 380cfm and the exhausts pass about 71 per cent of that – 270cfm. In factory trim, inlets flow about 320cfm. The ports are smaller than standard because Mark fills them up, but the improvement is more due to shape than size. The JB Weld material you can see is for reshaping to enhance swirl.

THE PRESSURE IS ON

THE PRESSURE IS ON

The pistons sit about 0.023in proud of the deck and the chambers are 57.66cc, resulting in 13.8:1 compression. Mark suggests that quite a few people will be sceptical of that compression ratio in conjunction with premium pump fuel, but it is what it is, he reckons.

As with any engine, the camshaft ties it all together. This custom Crane unit is pretty much the latest technology from the company. Mark was vague about lifts, but says the inlets are at least 0.700in while the exhausts are in the high 0.680in region. Duration is less secret, with 236° at .050in on the inlets and 246° at 0.050in for the exhausts. Because it’s a street motor, Mark believes it’s best to go big on the lift rather than the duration. This also gets the valves open quickly. It’s installed two degrees advanced.

LS-series engines have single-row timing sets, so the front cover has to be modified to take a double-row version. There are better factory cogs available (in slightly different sizes to accommodate different tunnel heights) and also better chains with thicker link plates. So that’s what’s fitted here. Not surprisingly, standard factory lifters won’t handle the cam, so Crane Ultra-Pro units have been fitted. They’re Teflon-coated locally by Jet-Hot. If they weren’t, they’d chew out the lifter bores.

The rockers are standard 1.7:1 factory units, but Mark replaces the GM needle rollers with Smith Bros trunnions. He worked with the development of these units to enhance oil supply and reliability.

IT’S CHANGE ON THE INSIDE THAT COUNTS

An aftermarket manifold may be the path to power, but it’s also the surest giveaway of a modified motor. That’s why Mark decided to push modification of the standard unit to the limit and it gets pretty thin in places. The ports are higher, bigger and reshaped. It’s ended up with a volume of about eight litres, a litre bigger than standard. That’s certainly improved performance, but Mark’s calculations indicate it probably needs a volume of about 12 litres to get past 700hp.

The finished motor was tuned on one of the Dandy Engines SuperFlow beds. The MAF has been deleted but it retains the factory ECU. Frank from Allsparks Performance wiggled the HP Tuners virtual controls while we all looked on. The factory timing was 18°, but Frank lifted that to 22° to get the ball rolling. That was raised as far as 28°, but the engine was happiest at 26°, so that’s the final figure. As is common practice, fuel was set rich to begin with, but pared back to 12.9 or 13:1.

The engine sounded very smooth – a good thing for the street. It was moving in a nice straight line but then turned a corner and started dropping off when the manifold reached its limit. At about 4700rpm it started pulling two inches of vacuum, and that figure climbed to about 5.8 inches by the end of the runs. Mark suggests that a lot of people will say the cam is the restriction, but it’s not – it’s the factory manifold, modified though it is.

So, if you want very strong street performance without attracting unwanted attention, a package like this could be the answer. Give Mark at MB Performance Competition Engines a call on 0418 506 615 and have a chat about it.

Mark believes that LS blocks are pretty good through the valleys but a bit too rough almost everywhere else

Mark believes that LS blocks are pretty good through the valleys but a bit too rough almost everywhere else

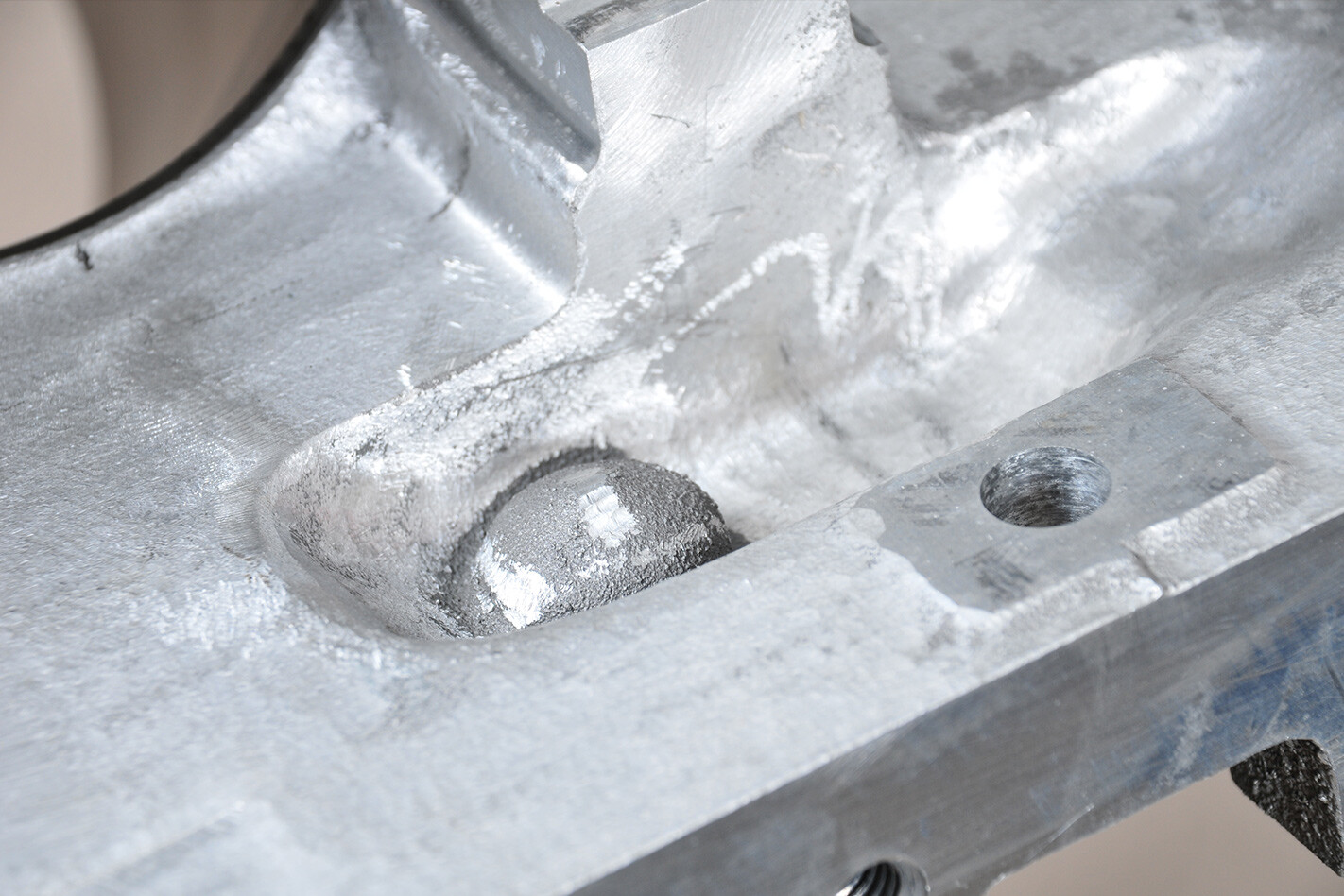

The block has had significant attention from the die grinder to improve oiling. Rough surfaces tend to catch solids

The block has had significant attention from the die grinder to improve oiling. Rough surfaces tend to catch solids

The skirts had a good going over

The skirts had a good going over

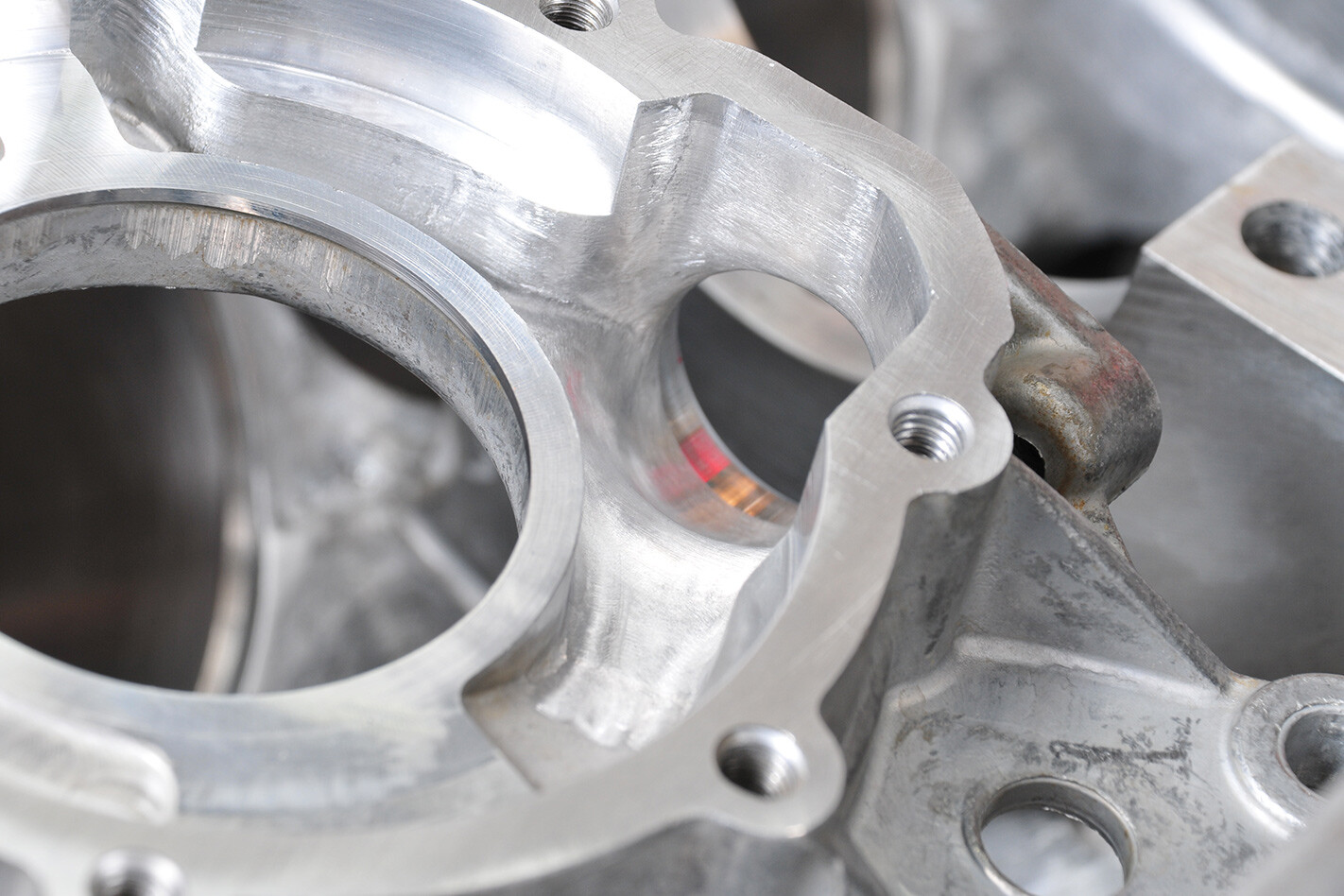

Flow paths in and out of the pump housing have been blended. Care is needed as this can be done incorrectly

Flow paths in and out of the pump housing have been blended. Care is needed as this can be done incorrectly

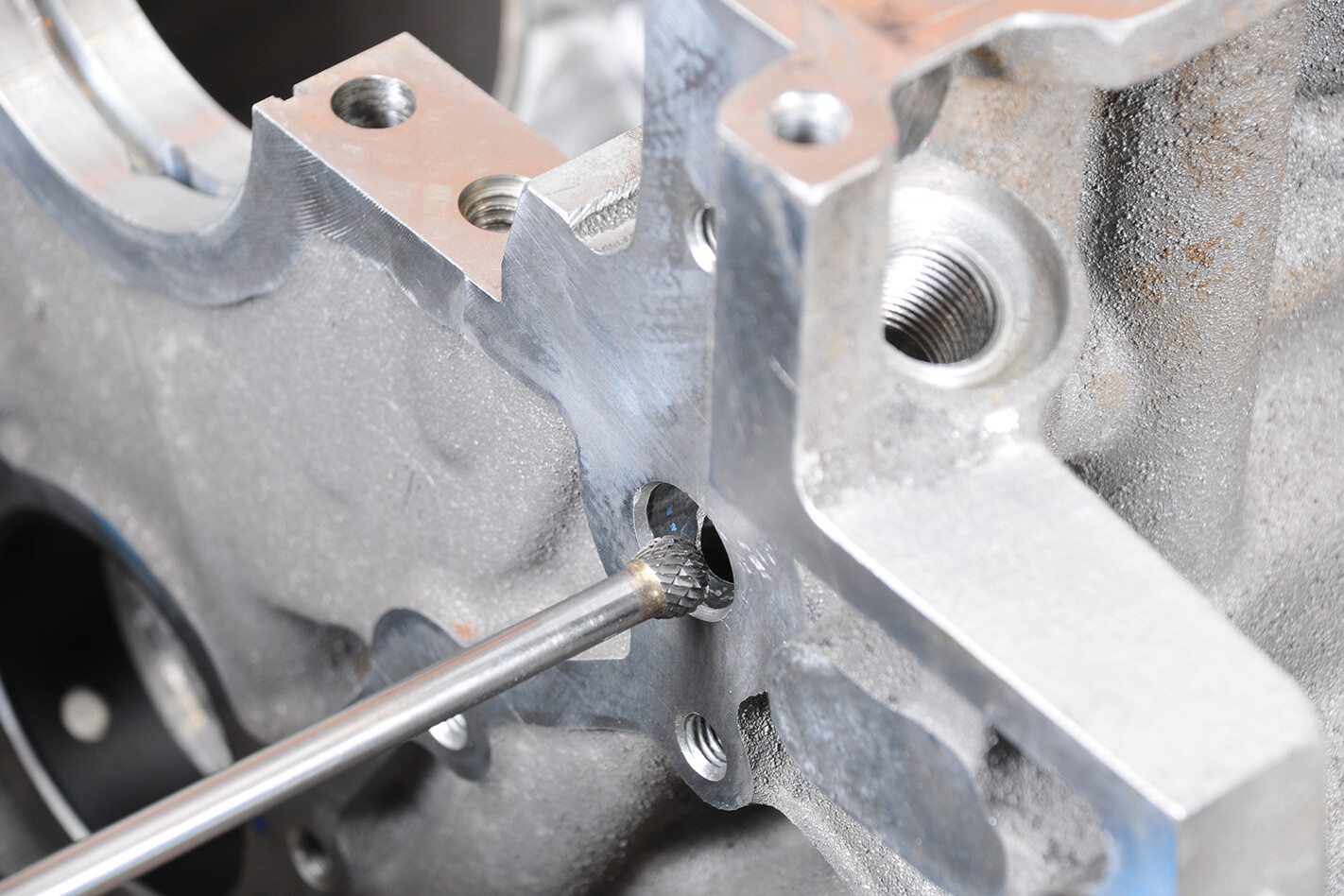

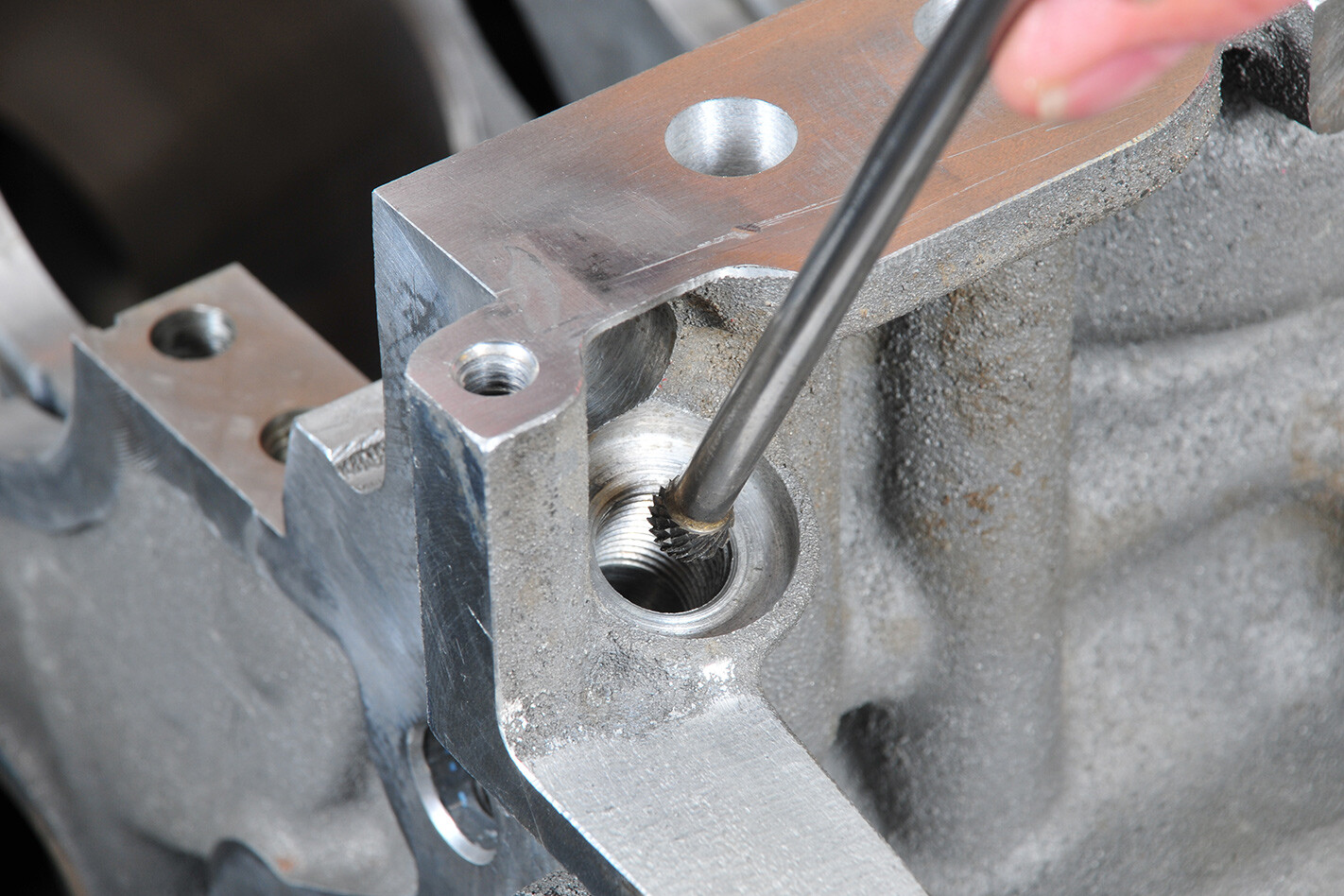

Oil gallery modification is certainly about smoothing and blending, but another problem is that the drillings often intersect less than perfectly

Oil gallery modification is certainly about smoothing and blending, but another problem is that the drillings often intersect less than perfectly

Extremely long burns are needed for the modification of oil galleries. It’s necessary to come in through different areas to reach some locations

Extremely long burns are needed for the modification of oil galleries. It’s necessary to come in through different areas to reach some locations

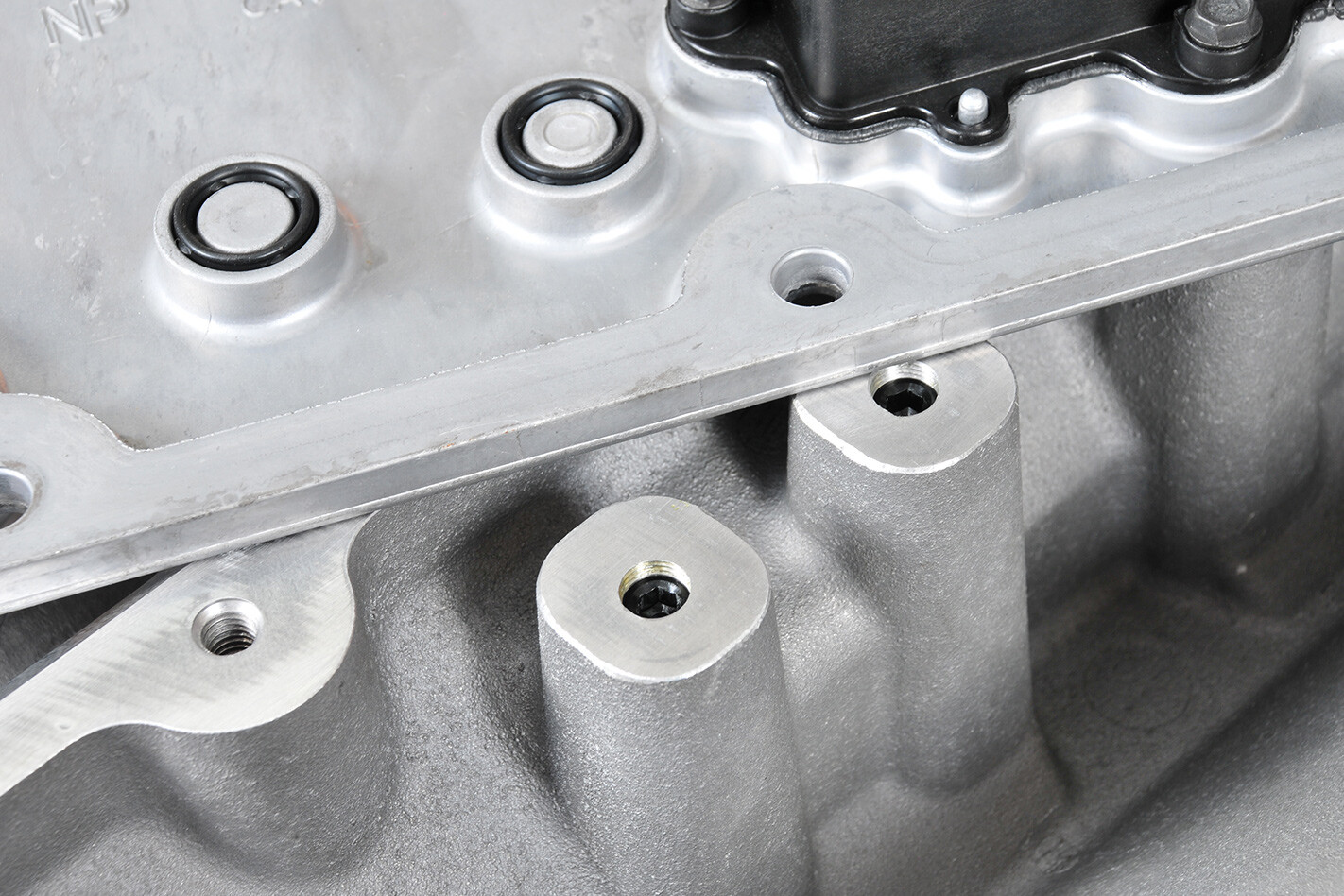

The posts in the valley are part of the LOMA (Lifter Oil Manifold Assembly) set-up that is used to turn the engine from eight to four cylinders as part of the Active Fuel Management/DOD system. Mark plugs these even though the LOMA is removed

The posts in the valley are part of the LOMA (Lifter Oil Manifold Assembly) set-up that is used to turn the engine from eight to four cylinders as part of the Active Fuel Management/DOD system. Mark plugs these even though the LOMA is removed

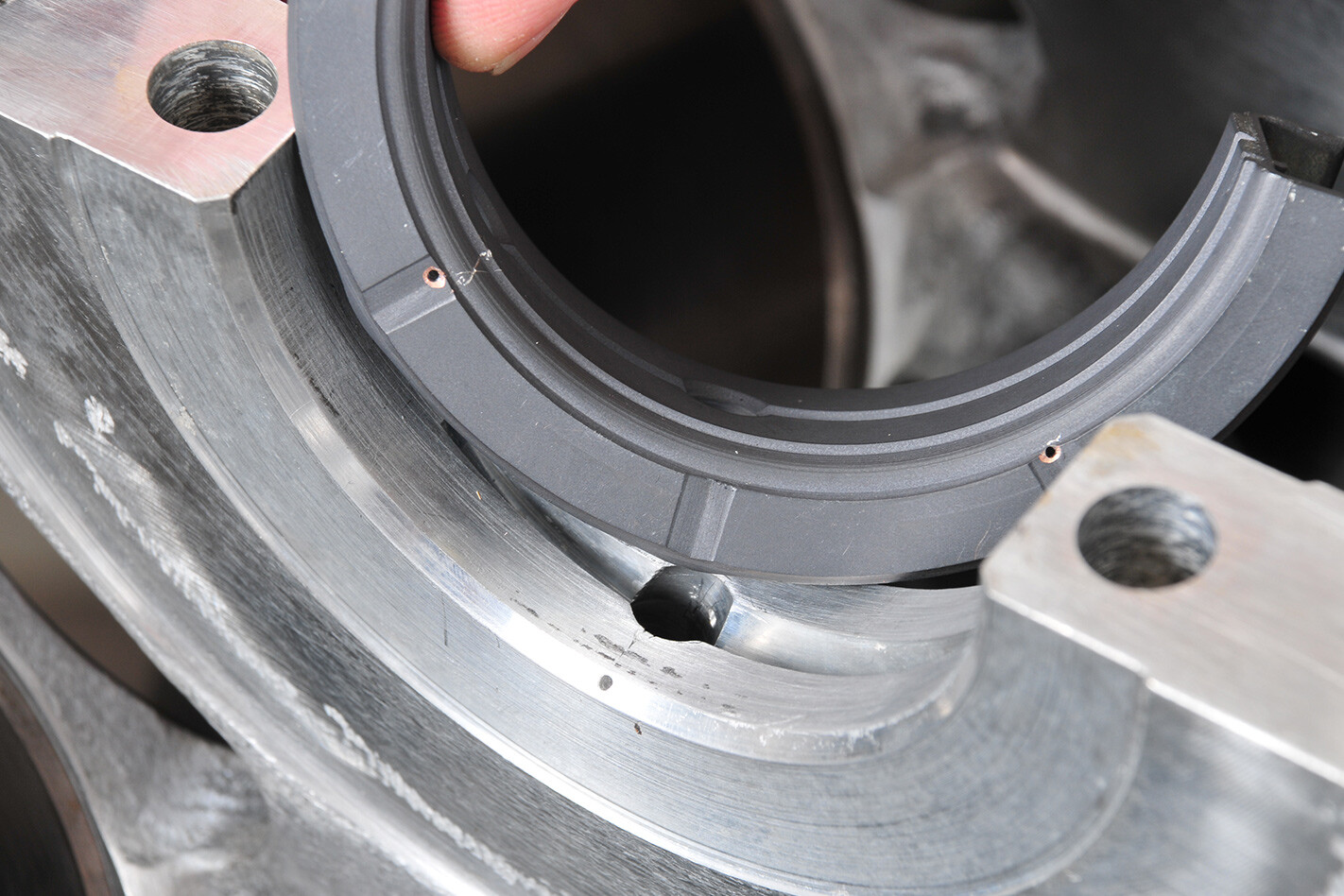

Note the extra oil holes in the face of the thrust bearing. Mark likes about 0.006in for crank float. Too much, he says, and you’ll lose oil pressure. At 0.010in things start getting knocked around

Note the extra oil holes in the face of the thrust bearing. Mark likes about 0.006in for crank float. Too much, he says, and you’ll lose oil pressure. At 0.010in things start getting knocked around

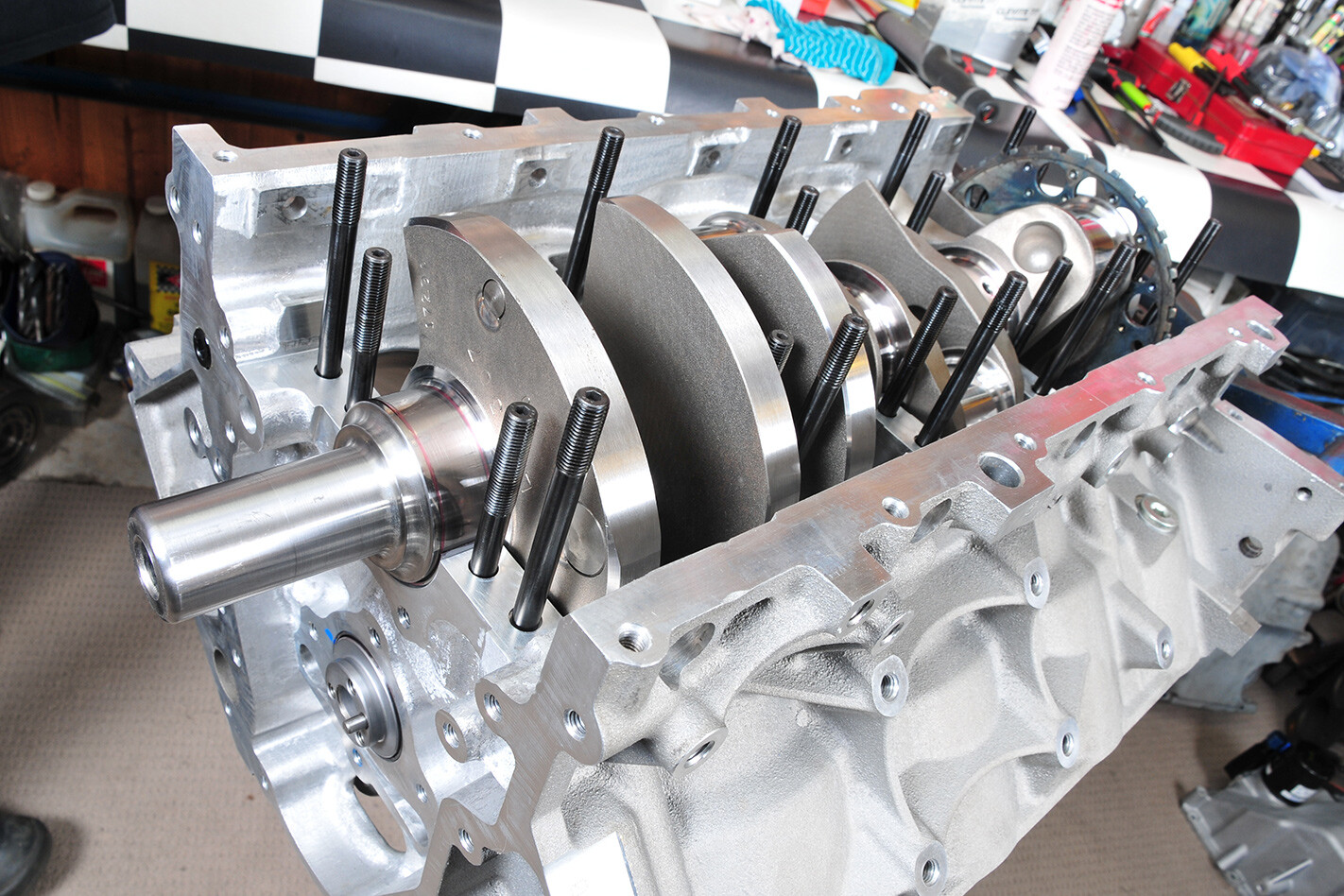

The crank was made in the US, and Mark’s seen American-made cranks like these make 3000hp and survive. He’s also seen supposedly good cranks out of China break at 1200hp!

The crank was made in the US, and Mark’s seen American-made cranks like these make 3000hp and survive. He’s also seen supposedly good cranks out of China break at 1200hp!

The thrust faces have greater area for obvious reasons. Mark used to get them specially made like this 20 years ago, but now the design is available off the shelf

The thrust faces have greater area for obvious reasons. Mark used to get them specially made like this 20 years ago, but now the design is available off the shelf

Short pistons and long rods are the ideal combination for strong torque and decent revs

Short pistons and long rods are the ideal combination for strong torque and decent revs

The timing set is GM – but a performance version. The chain has much tougher and thicker link plates

The timing set is GM – but a performance version. The chain has much tougher and thicker link plates

Standard caps are up to the task in this particular engine

Standard caps are up to the task in this particular engine

The one piece RAV valves are 2.16in and 1.6in with depressions in the chamber faces measuring 3-4cc

The one piece RAV valves are 2.16in and 1.6in with depressions in the chamber faces measuring 3-4cc

The lifters are Teflon coated by Jet-Hot. They’re set in the bores with the oil holes facing into the oil flow. So, opposite directions on either side of the block

The lifters are Teflon coated by Jet-Hot. They’re set in the bores with the oil holes facing into the oil flow. So, opposite directions on either side of the block

Springs are the latest from Crane. Mark can’t say much about them because at the time of writing they hadn’t been released. However, the rates are way less than expected for the cam. They’re duals, but without dampers

Springs are the latest from Crane. Mark can’t say much about them because at the time of writing they hadn’t been released. However, the rates are way less than expected for the cam. They’re duals, but without dampers

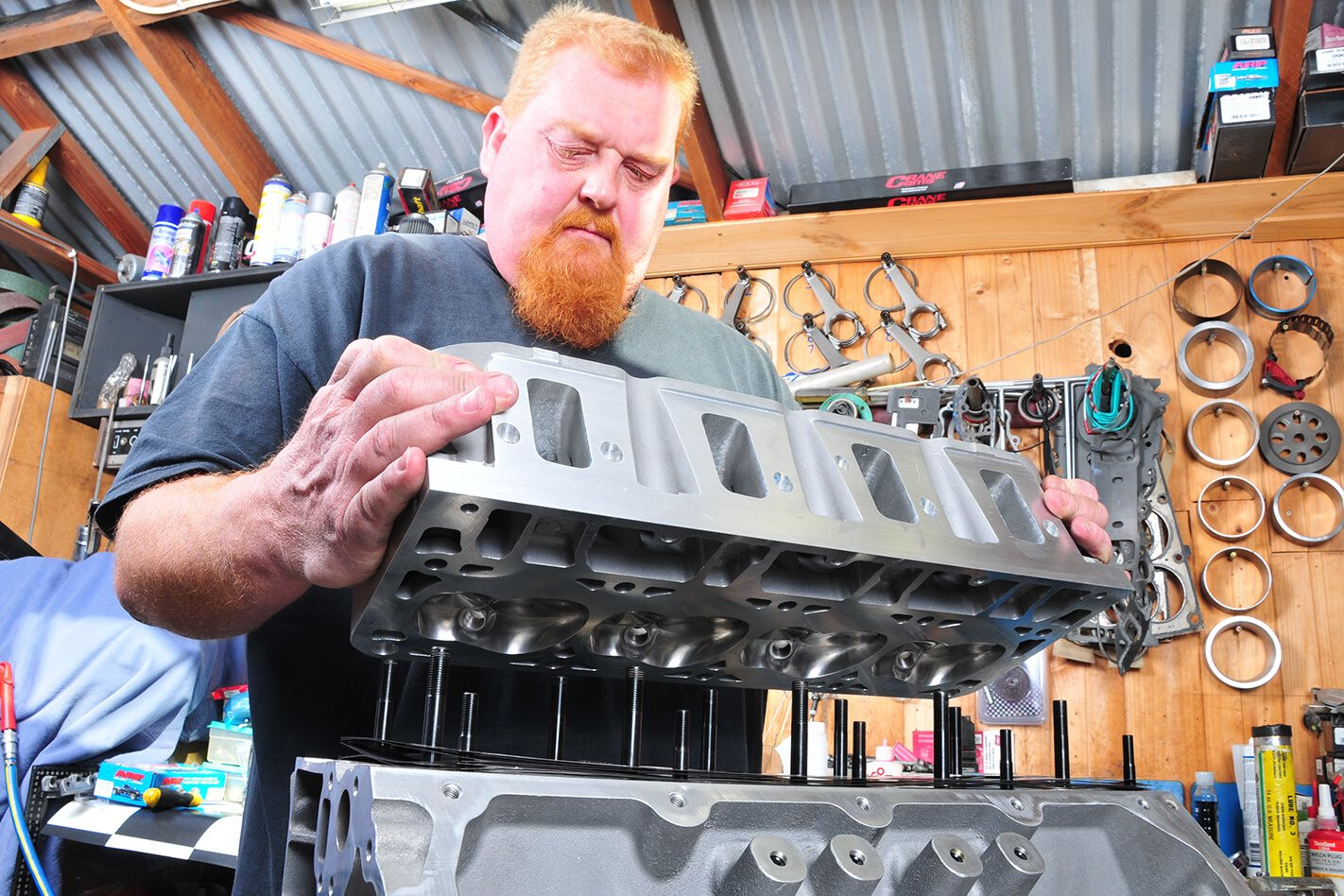

Obviously, sticking with standard heads means major modification. The good thing is that they look standard from the outside, which is the whole point

Obviously, sticking with standard heads means major modification. The good thing is that they look standard from the outside, which is the whole point

It’s a GM LS9 composite gasket. There are internal layers measuring 0.012in, 0.008in and 0.006in and deleting these selectively allows adjustment

It’s a GM LS9 composite gasket. There are internal layers measuring 0.012in, 0.008in and 0.006in and deleting these selectively allows adjustment

Jett Engineering made the pushrods and Mark says they’re some of the most accurate he’s seen. Inlets are 7.300in and exhausts are 7.275in with 0.128in wall thickness

Jett Engineering made the pushrods and Mark says they’re some of the most accurate he’s seen. Inlets are 7.300in and exhausts are 7.275in with 0.128in wall thickness

Without modification the standard factory rocker bearings would fail with the cam fitted to this engine, so the mods are vital

Without modification the standard factory rocker bearings would fail with the cam fitted to this engine, so the mods are vital

You can get an idea of how far Mark has opened out the standard manifold here. Manifold modification has been the cause and limit of increased power

You can get an idea of how far Mark has opened out the standard manifold here. Manifold modification has been the cause and limit of increased power

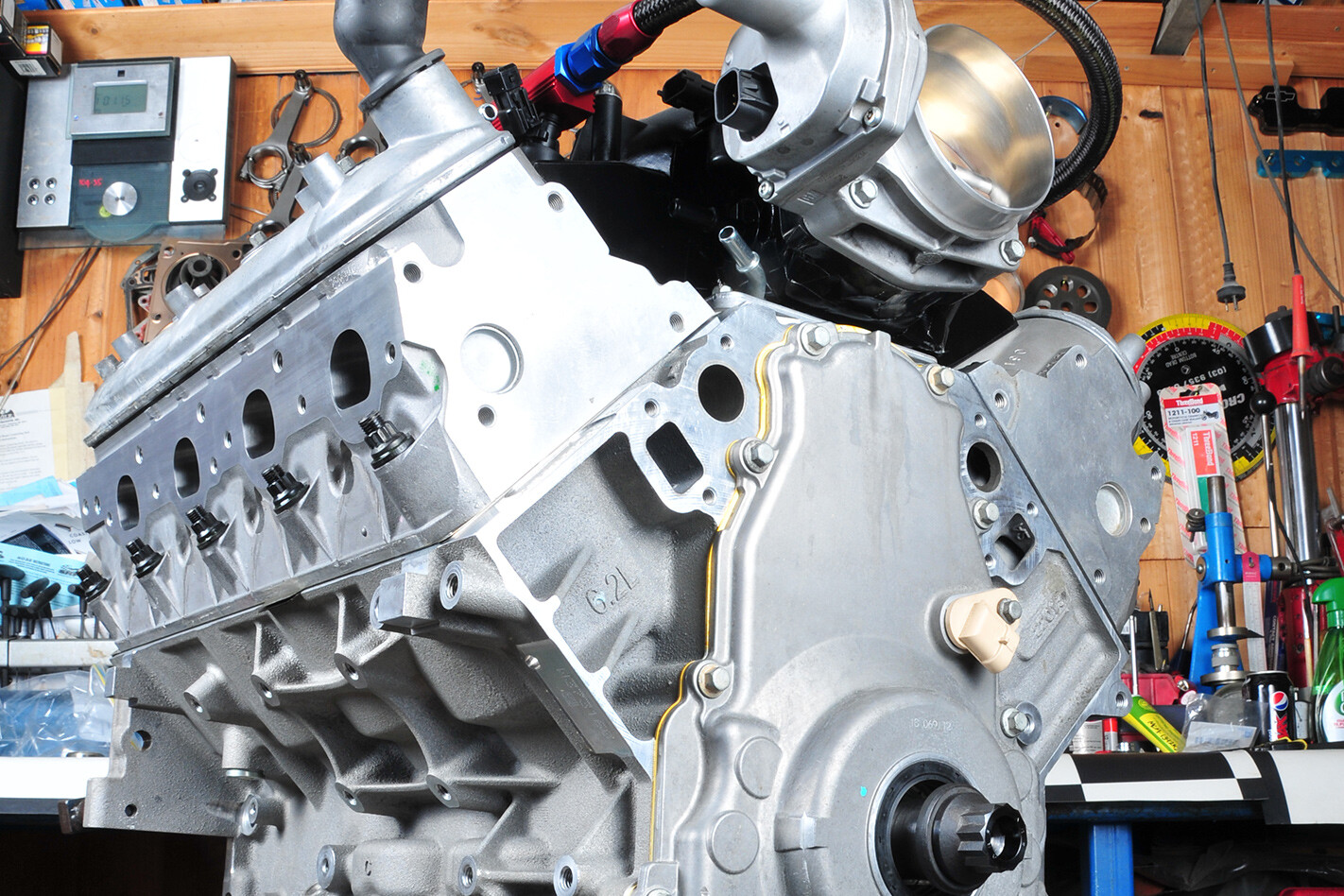

Apart from the bright red rails the package looks pretty standard to a critical, official eye

Apart from the bright red rails the package looks pretty standard to a critical, official eye

The sump also looks standard inside and outside, but it’s also seen the die grinder, even inside the plumbing

The sump also looks standard inside and outside, but it’s also seen the die grinder, even inside the plumbing

The ports have been match-ported, which makes them bigger. Standard manifold outlets are even too small for standard heads in Mark’s opinion

The ports have been match-ported, which makes them bigger. Standard manifold outlets are even too small for standard heads in Mark’s opinion

Ready for the dyno

Ready for the dyno

The throttlebody is also a factory unit, but substantially modified. The changes resulted in an extra 58cfm. Care is needed because flow can be hurt badly if this is done incorrectly

The throttlebody is also a factory unit, but substantially modified. The changes resulted in an extra 58cfm. Care is needed because flow can be hurt badly if this is done incorrectly

One of Lou’s (Dandy Engines) SuperFlows. A combination similar to this made 758hp with a Hi-Ram, but considerably less torque

One of Lou’s (Dandy Engines) SuperFlows. A combination similar to this made 758hp with a Hi-Ram, but considerably less torque

Comments