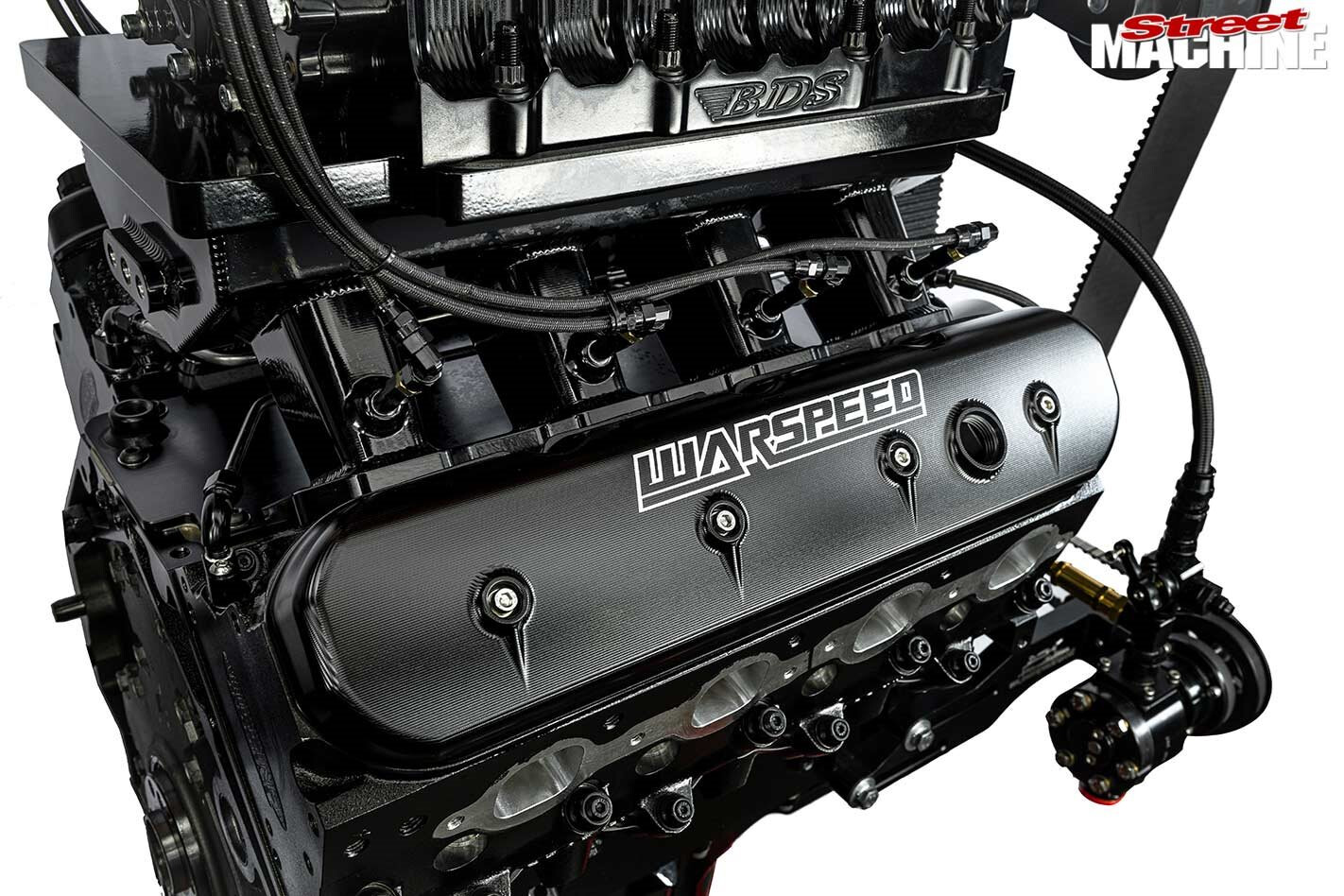

While we are used to seeing big-inch LS combos, the man behind Warspeed, Troy Worsley, has made some interesting changes to this small-cube build.

This article was first published in the April 2020 issue of Street Machine

“We started with a Dart SHP LS Next block and went for a big bore and standard stroke to try and get some rpm into it,” Troy says. “There was a GM engine that came out in America that had a steel crank like an LSA but had a dry sump, so we had to cut the snout off and keyway it. They’re a really nice crank and can handle the abuse of the burnout-type cars, plus it has a six-bolt pattern on the flange instead of eight like an LSA.”

While it will run on methanol, the 388ci’s compression is a fairly tame 10.5:1, and Troy hasn’t gone exotic on the oil system, either. “It uses a wet sump set-up with a VE-style pan, as they work really well. We put a new baffle in it, but it’s solid and holds nine litres of oil.”

The heads are six-bolt hybrid units by Nathan Higgins; they have a serious set of lungs but don’t come with the drawbacks of hardcore race parts. “These heads take an LS3 intake runner, but everything inside is LS7-spec, like valves and rockers,” Troy explains. “This is great because LS3 intakes are much easier to come by than the square-port LS7 ones.”

The engine runs a WASP01 hydraulic-roller cam, the first custom grind Troy offered through Warspeed. “The specs are in the vicinity of 250s and 260s duration, with a 114 LSA and 0.630in lift. It sacrifices a bit of power, but I did that to help bleed off a bit of cranking pressure, which reduces the risk of blown-out head gaskets. Because the LS heads are so good, you don’t need as much cam.

“I run hydraulic-roller cams in burnout-type engines, just to soften the hit on the valvetrain when running near the limiter,” he continues. “An LS will always zing straight to the limiter, and solid-roller cams have much more valvetrain weight. You can run less spring tension with a hydraulic-roller and reduce the stress on many parts.”

All that work is hidden under a Shaun’s Custom Alloy intake manifold, BDS 8/71 billet blower and Enderle Big & Ugly hat, ready to scream.

“It is set up for 15psi at the moment, but we could put more in it,” says Troy. “It has a fire ring-style head gasket, so you could put 30psi in it. Does the customer need it? Not really, but it has the potential there if they want to race it.

“This thing should make 1200-1300hp and it’ll go over 8000rpm, but the plan is to be maintenance-friendly.”

HAT TRICK

THE Enderle billet fuel pump flows about nine gallons per minute, and there are eight mechanical squirters in the runners and another eight in the hat. “We have port-and-hat mechanical injection on it, which was done in conjunction with Wayne Newby,” Troy says. “I bounce a lot off Wayne because he is very switched on with mechanical injection.”

WARSPEED INDUSTRIES,

ST MARYS

Comments