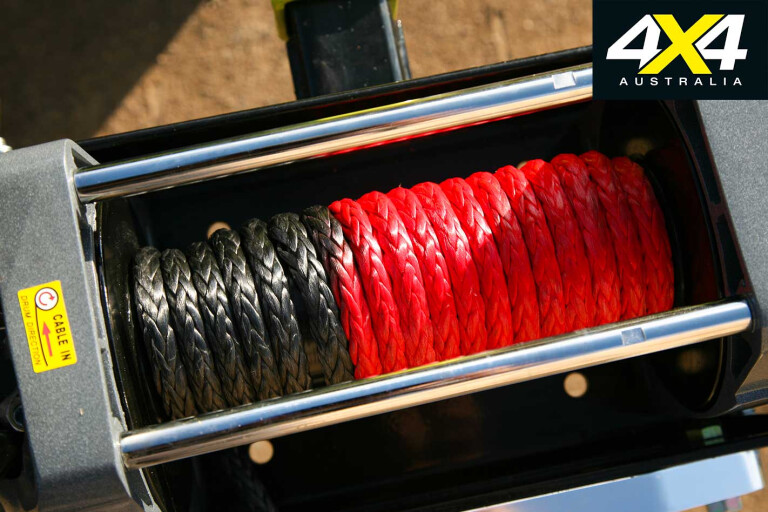

THE synthetic rope has fast become the go-to option in an off-roader’s recovery arsenal. Stronger, lighter and more versatile than old-school steel ropes, synthetic rope now holds a permanent position on the winch drum of countless tourers around the world.

“The introduction of synthetic rope a few years ago was a game changer in the winch industry,” Ironman 4x4’s director of 4x4 products, Adam Craze, explained. “The rope had been around for a long time, previously used for other industries including marine. It made a progression into 4x4 winches and hasn’t looked back.”

In fact, synthetic rope sales now far exceed those of steel cables. “Synthetic rope sales have far surpassed steel cable sales in the last 10 years I have been involved in the industry,” said Daniel Kozaris, the owner of Carbon Winches Australia. “The market is generally well-attuned to the benefits of synthetic rope for 4x4 recovery.”

Adam Craze added that Ironman 4x4 currently sells 70 per cent rope versus 30 per cent steel; while Jim Markham, the owner of JM Rigging Supply, told us he currently sells about 50 Dyneema synthetic lines to one steel line for off-road use. “I take steel winch lines off winches and replace them with Dyneema on a regular basis,” Jim said. “I have never replaced a Dyneema line with steel.”

Synthetic ropes are made using polyethylene, with Carbon Winches Australia using Dyneema SK75 fibre for its ropes used for electric winch recovery. Dyneema fibres are made from Ultra High Molecular Weight Polyethylene (UHMWPE), which is claimed to be up to 15 times stronger than steel on a weight-for-weight basis.

“Dyneema is produced in a patented gel-spinning process in which the fibres are drawn, heated, elongated, and cooled,” the Dyneema statement reads. “Stretching and spinning leads to molecular alignment, high crystallisation, and low density. Dyneema has extremely long molecular chains that transfer load more effectively to the polymer backbone.”

Jim Markham, from JM Rigging Supply based out of Utah, USA, has been in the rigging industry for more than 30 years, and he told us he also uses Dyneema fibre manufactured by DSM in the Netherlands.

“Dyneema rope is supplied basically in what we call a 12-strand single braid,” Jim said. “The common grade of Dyneema is an SK75 and the common size used is 3/8-inch diameter. Depending on the manufacture and the steps it goes through will determine the breaking strength, which can range from 17,000lb to 20,000lb.”

Dyneema rope isn’t just a recovery tool for a 4x4er, you’ll also find it’s used on sailing ropes, trawl ropes, anchor ropes, mooring ropes, climbing ropes and even paragliding lines.

Steel vs Synthetic

SYNTHETIC rope may lead steel cables as the popular choice, but that doesn’t make steel redundant for an off-roader.

“Steel cable is still relevant for certain applications, mainly outside of 4x4 recovery use. The logging industry, tow trucks and similar industries still find that steel cable provides a longer lifespan and lower cost in situations where the added risks and disadvantages can be managed and the overall benefits still allow steel cable to be the choice on their winches,” Dan Kozaris told us.

Still, steel is heavier than synthetic rope, which means it adds more weight to the front-end of vehicle – taking 10-15kg off the winch will greatly reduce the impact to the front suspension.

Synthetic rope is also safer to handle, stronger than the equivalent-diameter steel cable (as mentioned, up to 15 times stronger on a weight-for-weight basis), can float on water (ideal for water-logged recoveries), doesn’t go mouldy, can be handled without gloves (no risk of metal strands embedding in your skin), and, as Dan from Carbon Winches Australia told us, comes in a bunch of pretty colours. Dyneema rope also requires a minimum bend radius of three inches, which is much more favourable for off-road use.

ARB’s Shannon Diedrich explained that another benefit of synthetic rope is that it can be respliced – joining two ends of a rope without using a knot – so if it breaks it can be rejoined and remain strong. She also confirmed that a synthetic rope doesn’t bind on the winch drum.

Jim Markham reiterated that point: “The biggest advantage to Dyneema rope is that if you break it out on the trail you can simply tie it back together in a knot. Yes you will lose about 40 per cent brake of the rope at the knot, but have you ever tried tying cable in a knot? A broken steel cable on the trail generally means no more winch.”

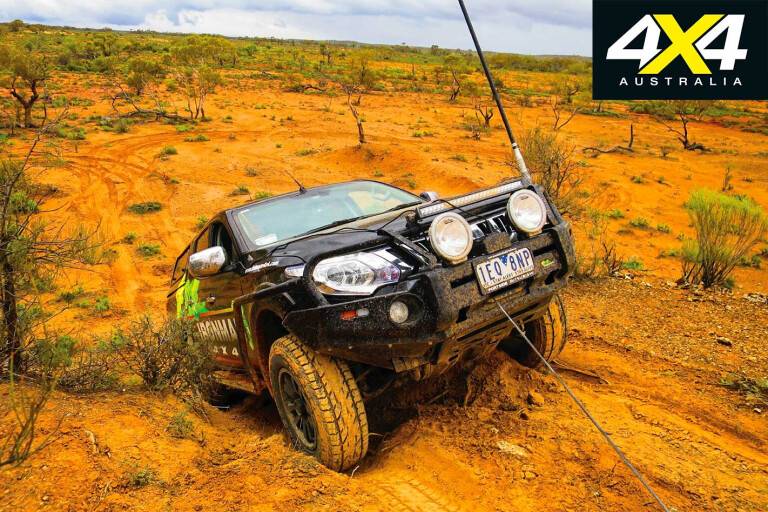

Making synthetic rope even more lucrative to the hardcore off-roader is the fact it doesn’t store energy and therefore won’t ‘whip back’ like a steel cable. The rope’s lower elasticity means there’s less chance of it flying back, but Dan Kozaris advises that a “winch damper blanket should still be used for safe recovery practice”.

“By design synthetic rope doesn’t store nearly as much potential energy, so if the rope should snap it won’t be nearly as dangerous,” Craze added. “Synthetic also doesn’t suffer from filings and burrs the same way steel cable does, meaning it’s a lot safer to handle.

“It also has built-in tension within it as it’s not nearly as malleable as rope, so it has a lot more spring to it. There is no questioning it, synthetic rope is safer,” he said.

A steel cable on the other hand holds and builds up kinetic energy stored through the length of the winch line. “Bends, kinks, splinters and broken wires all contribute to premature failure of a steel winch line,” Jim said. “Use and bend fatigue also contribute to early failure. When a steel cable fails or breaks it is pretty violent. Broken steel winch lines have been known to break windows, go through radiators and worst yet, hurt and even kill people.”

Steely Resolve

THE MOST common stranding of steel cable used for winching is a 7x19-inch strand. “This means seven strands of 19 wires wrapped around a core,” Jim added. “The 7x19 strand is a common low-grade ‘commercial’ or basic-use cable and is mass produced with little or no quality control.”

The breaking strength on a basic 3/8-inch 7x19 cable is 14,400lb, so Jim recommends punters opt for 3/8-inch 6x36 or 6x37 for winching. “This cable is made for winching, is more flexible and carries a higher breaking strength of 15,100lb,” he said.

Bend Fatigue

FORCING a steel cable to conform to a small-diameter winch is a common issue and it even has a name – bend fatigue – and it’s what causes broken wires on the cable’s outer strands.

“Steel cable in 3/8-inch diameter has a minimum bend radius of about six inches,” Jim Markham explained. “This [3/8-inch] diameter is the most common size installed on off-road winches. Most off-road recovery winches are a lot less than a six-inch drum diameter.”

Pulling a load with a withering cable causes the wire to splinter even more, this weakening it further before it’ll eventually snap.

“Ever notice how the wire curls like a pig’s tail when you pull it off the drum? It does this because you have forced the wire to bend way below the minimum bend radius, kind of like running ribbon over scissors to get it to curl,” Jim said. “This makes the wire winch line harder to pull out and much more difficult to use. These curls can also cause kinking in the cable which severely weakens the strength.”

Cons

DESPITE its many advantages, there are a few drawbacks when using synthetic rope as a recovery tool. A key concern agreed to by the experts is that they’re more at risk of abrasion damage, as the rope is susceptible when it rubs against surfaces.

“Abrasion damage is more of a risk, so you need to be much more vigilant in protecting the rope during recoveries to minimise breakage due to sharp edges on rocks or trees,” Kozaris explained.

“Users should ideally set up the winch recovery so that the rope is not in contact with any surface between the vehicle and the anchor point,” he said. “If it is impossible, then protect the rope prior to loading it up from abrasion against any surface. You can use a jumper, an old hessian bag, a car floor mat; whatever is available to stop it rubbing on abrasive surfaces.”

Craze added that something like a sleeve over the rope or tarp beneath it will limit abrasion damage.

It’s also important to keep in mind that synthetic rope won’t last as long as a steel cable, and it will need to be replaced a lot more frequently. “It degrades under UV exposure and can lose up to half its strength in six months of sunlight exposure,” Diedrich explained. “Warn recommends replacing its synthetic ropes every 12 months.”

Steel cables are more durable when working in rough, rocky areas, and they will handle more punishment. Synthetic ropes, on the other hand, require more maintenance. “Synthetic rope needs more care and attention, especially when it is brand new,” Craze said. “You will need to spool it on under tension, otherwise during a recovery the rope will slice through the layers on the drum and sometimes get stuck.”

ARB’s Diedrich added that other disadvantages are susceptibility to damage from shock loads, susceptibility to breakage due to wear and rubbing on ground surfaces, susceptibility to heat damage, and loss of strength due to winch drum temperatures.

A synthetic rope will cost more to purchase and maintain than a steel cable, but Adam Craze insists that it’s a much better option: “There’s less weight on suspension, less weight on the bullbar, it’s safer and easier to use. The extra cost at the start will soon be forgotten.”

Be Careful

SYNTHETIC ropes aren’t all created equal, so it’s important to research and buy from reputable brands, as Jim Markham from JM Rigging Supply explained.

“The raw Dyneema fibre is made by DSM in the Netherlands. The manufacturer then strands the rope,” he said. “This rope is mass produced with very little quality control in China and throughout Asia. Be aware of blended ropes, as pure Dyneema has been deemed the best for off-road recovery. I only sell quality Dyneema rope manufactured in the United States under strict quality control.”

Synthetic rope offerings on the market

ARB

ARB STOCKS a Warn Spydura Synthetic rope (30.48m x 9.5mm) as well as a range of Dynamica ropes: 8mm x 30m, 8mm x 35m, 8mm x 40m, 8mm x 45m,10mm x 30m, 10mm x 35m, 10mm x 40m, 10mm x 45m, 11mm x 40m, and 11mm x 45m.

Head online for specs, pricing and more information.

Website: www.arb.com.au

Carbon Winches Australia

Carbon Winches Australia stocks 10mm x 24m Dyneema winch rope replacements, which are good for winches up to 13,000lb. It also stocks 12mm x 24m Dyneema winch rope, good for winches up to 17,000lb.

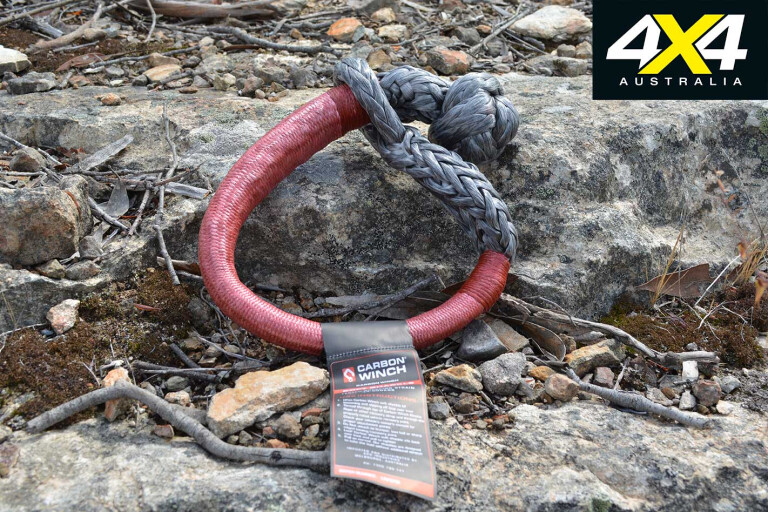

The Australian company also stocks Monkey Fist Dyneema soft shackles and will soon release a new rope option that has far greater abrasion resistance properties than the standard Dyneema. Stay tuned.

Ironman 4x4

IRONMAN 4x4 offers two winches with 8mm and 9.5mm cable. It also sells synthetic rope separately from its winches for those wishing to upgrade, offering two different sizes based off the size of your winch and their respective ratings.

Website: www.ironman4x4.com

JM Rigging Supplies

THE US-based company stock 1/4”, 5/16”, 3/8”, 7/16” and 1/2” Dyneema rope, with different colour options available depending on size and stock availability.

“These diameters are for winch lines as well as soft shackles,” Jim said. “Being that I make all my lines and soft shackles in-house, I can make any length desired in winch lines and soft shackles. We also make the lines per the specs on your winch so connection and installation are generally pretty easy and user-friendly. I have the ability to make and control exactly what you want.”

Website: www.jmrigging.com

Soft Shackles

SOFT shackles are a lightweight alternative to the traditional steel bow shackle, made using Dyneema and equivalent fibres, and they are said to be easier and safer to use (no more metal projectiles hurtling toward your windscreen).

“Replacing a commonly used metal shackle with a rope substitute is always a good option in a recovery situation,” Craze said. “The chance of an injury or death is significantly reduced by removing metal objects that are commonly used during any recovery.”

Steel shackles are limited by their size, whereas soft shackles are more user-friendly, better and quicker for gathering bulky recovery straps. “They are also light so they float in water, mud and snow and require no tools to use,” Jim said. “Also in a rollover situation, steel shackles fly around the rig hitting people and breaking things; plus how many times have you lost the pin?”

Dan Kozaris added that synthetic rope has had such a positive impact on the off-roading community that soft shackles should have no problem cracking the market. “People already have had a great experience with synthetic rope in winches, so this confidence should allow the end user to adopt the use of soft shackles for recovery as a no-brainer option compared to a steel bow shackle,” he said.

COMMENTS