Snapshot

- First blocks will be CNC-machined

- Will use standard-design K20 or K24 heads

- Should make up to 800hp

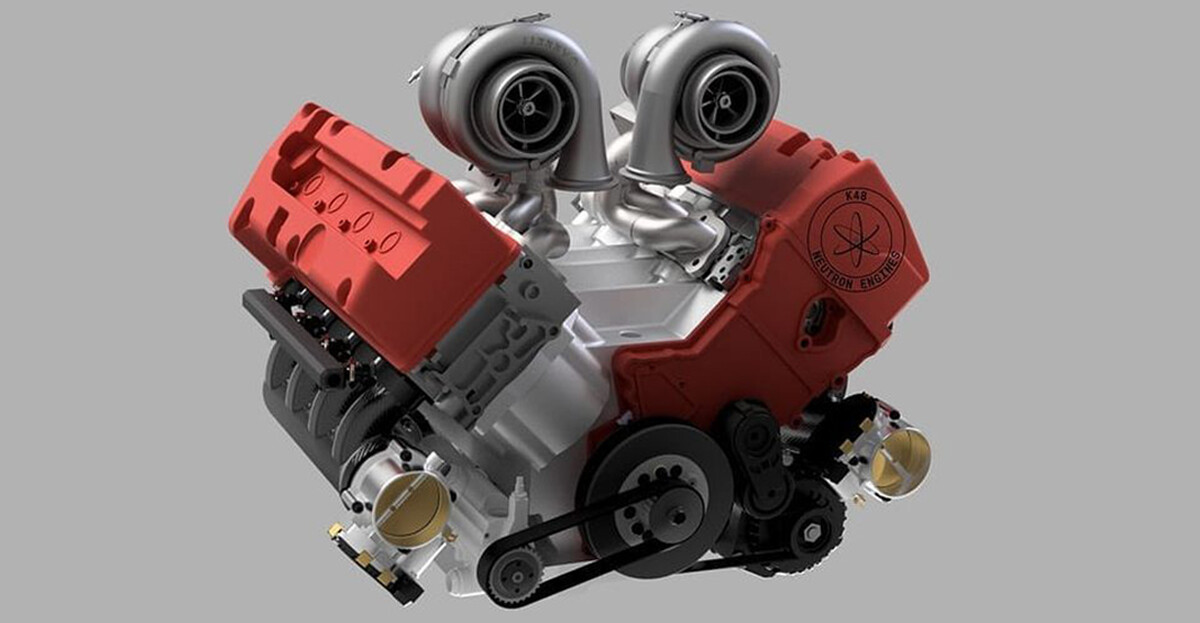

An Arizona-based mechanical engineer is developing a flat-plane 5.0-litre V8 based on Honda’s K-series four-cylinder engine, which will use off-the-shelf heads.

Craig Williams has been working on the quad-cam ‘K48’ design for over five years in his spare time, making extensive use of computer-aided design and 3D printing to bring the custom engine to life.

Williams told Dust Runners Automotive Journalhe began with the goal of making more horsepower per litre than Ferrari’s benchmark naturally-aspirated V8 — the 458 Speciale’s 4.5-litre, 570hp F136. “It started off as ‘let’s just see if I can’, then ‘okay, I’m working on this’, and then ‘holy crap, I’m actually doing this!’”

He said he soon realised he could “go a lot higher than that” with his flat-plane crank V8 design. In N/A form, Williams is now hoping to make between 750hp and 800hp (“if not more”) with a redline of 10,000rpm.

As explained here, a flat-plane V8 design fires one cylinder per 180 degrees of rotation, making for a well-balanced crank with less counterbalancing required. That in turn creates a lighter, faster-spinning crank perfect for a high-RPM motor.

Since the K42’s introduction in 2001, the Honda four has proven a popular engine swap for both front and rear-wheel-drive cars, especially among drifting circles.

Williams says he chose the K-series Honda motor for its high-revving capabilities in naturally-aspirated applications. The S2000’s F20 platform was another option, but Williams wanted to avoid the extra cost associated with S2000 parts.

The first engine blocks will be CNC-machined, though Williams says he will move to casting engines if his first builds succeed. Inside the first engine will be a custom crank, rods and pistons, though he says stock K24 pistons would also be usable.

On a typical V8, cylinder head designs are ‘mirrored’, keeping the engine symmetrical. To drive down manufacturing costs, Williams’s K48 instead uses two identical K20 or K24 heads.

Timing for one head is driven by a standard front-mounted system, while another timing chain on the rear of the block will control the ‘flipped’ head. Reverse-grind cams will sit in the rear-facing head.

Issues with placing the timing chain tensioner led Williams to create a ‘hot V’ layout, with the exhaust manifolds facing inward. The result is a distinctive header set-up, suitable for either NA application or a large, twin-scroll single turbo.

Williams’s final product will be much slimmer than a comparable 5.0-litre Coyote V8 block. The exhaust layout would allow for a compact twin-turbo package, which is another item on the designer’s radar.

The flywheel area will facilitate several bolt patterns. The first planned by Williams are GM’s six-bolt layout and Honda’s J35, alongside Porsche 911 and Nissan CD009 configurations.

There’s still plenty of work to be done before the first K48 comes to life, but Williams has already received a set of eight custom rods and lightened CP pistons for the build.

You can keep up with the build on Williams’s Instagram page @neutronengines.

Comments