You would think the guy who invented a recovery device that helps take you anywhere might have a bit of an idea when it comes to building a touring rig that promises the same. And, in the case of Brad McCarthy, the brains trust behind MAXTRAX, you’d be absolutely spot-on, as his big, six-wheel Land Cruiser 200 Series proves.

As with all perfect things, this LC200 is the result of a lengthy period of time – say, a couple of years all-up – researching, experimenting and tweaking before Brad was happy to hit the go-button. Brad is a big fan of beach and desert touring, so the vehicle had to be more angled toward that type of driving, without sacrificing general driveability or, for that matter, go-anywhere capability (the Cruiser is definitely not confined to just those terrain types).

So Brad was sure to take his time getting it all right, starting off with where the idea originated: in the Australian desert, a few years ago.

So Brad was sure to take his time getting it all right, starting off with where the idea originated: in the Australian desert, a few years ago.

“I did a couple of trips with the Australian army back in 2012 and 2013 testing the Mercedes G-Wagens,” Brad said. “There were a couple of six-wheel drive versions of that – LRPVs – in the convoy and they were just so capable and so comfortable in that rough terrain. I rode in a few during those expeditions and, just because of the length of the wheelbase, they were so much more comfortable.”

This first experience of the comfort and stability offered by a couple of extra wheels out the back was followed by another desert stint, this time with some modified Land Cruisers, which allowed Brad to undertake a slightly more direct comparison of four wheels versus six.

“We did a trip testing some Land Cruiser-based LRPVs in 2015,” Brad explained. “We went across the Simpson driving a couple of six-wheel drive (6WD) Cruisers. I had my four-wheel drive, a 100 Series Cruiser, and I was driving that and then I jumped in one of the 6WDs for a few hours and I was like, ‘it’s like chalk and cheese’; so much more comfortable in really rough terrain and I went ‘yeah, I really like this’, so I thought I might build one. So that was the impetus for it.”

“We did a trip testing some Land Cruiser-based LRPVs in 2015,” Brad explained. “We went across the Simpson driving a couple of six-wheel drive (6WD) Cruisers. I had my four-wheel drive, a 100 Series Cruiser, and I was driving that and then I jumped in one of the 6WDs for a few hours and I was like, ‘it’s like chalk and cheese’; so much more comfortable in really rough terrain and I went ‘yeah, I really like this’, so I thought I might build one. So that was the impetus for it.”

IN THE BEGINNING

To fit an extra pair of hoops under the Cruiser, Brad enlisted Australian Expedition Vehicles’ (AEV) Mick McMillan, having worked with Mick on the earlier G-Wagen testing for the ADF.

In fact, Mick was a Major at the time of testing, and it was through the desert testing of the Mercs that he first came up with the idea of AEV, as Brad explained. “It was interesting, because when we were doing that testing, during the two trips, I drove my 100 Series and I never had any mechanical problems the whole time,” he laughed.

In fact, Mick was a Major at the time of testing, and it was through the desert testing of the Mercs that he first came up with the idea of AEV, as Brad explained. “It was interesting, because when we were doing that testing, during the two trips, I drove my 100 Series and I never had any mechanical problems the whole time,” he laughed.

“These were all brand-new Mercedes and I had a 2005 100 Series, and every time we pulled up to fix something in the G-Wagens I would wind down the window and say you need Land Cruisers! They’d just reply ‘yeah we know, but we’re getting these things’.”

It was during all this testing that Brad and Mick started chatting about how much more suitable an LC200 – in extended, six-wheel form – would be for this type of expedition-style remote-desert travel.

“We were having a chat and Mick said, ‘you know, we really do need a Land Cruiser; I am going to set up a company and start building them’, so that’s how he started,” Brad said.

“We were having a chat and Mick said, ‘you know, we really do need a Land Cruiser; I am going to set up a company and start building them’, so that’s how he started,” Brad said.

Since then, AEV has produced a number of 6WD Cruisers, utilising the many years’ of experience from all that testing and combining it with a unique drive system courtesy of Jason from JMACX Off Road Solutions, another Queensland-based company well-known for its coil conversion kit for 70 Series Land Cruisers.

ALL WHEELS GO

Getting the extra-wheel configuration to work ‘as standard’ at the rear of this stretched Cruiser is the result of AEV fitting what is basically a double JMACX coil set-up with a few trick components to ensure it works a treat.

“The system is basically a double JMACX with a drive-through centre diff,” Brad explained. “So you’ve got good articulation, and the six-wheel drive system just happens automatically. So, normally, if you’ve got it in four-wheel drive, it’s driving just the four wheels. As soon as there’s 20mm of slip in that middle axle it engages that centre diff and locks in the rear axle, and then you’ve got six-wheel drive. You don’t have to press any buttons or engage anything, it just automatically occurs as you need it.”

“The system is basically a double JMACX with a drive-through centre diff,” Brad explained. “So you’ve got good articulation, and the six-wheel drive system just happens automatically. So, normally, if you’ve got it in four-wheel drive, it’s driving just the four wheels. As soon as there’s 20mm of slip in that middle axle it engages that centre diff and locks in the rear axle, and then you’ve got six-wheel drive. You don’t have to press any buttons or engage anything, it just automatically occurs as you need it.”

Brad reckons it transforms the Cruiser’s tractive capabilities, making it – nearly – all too easy. “As soon as you lose traction you’ll feel the system kick in, it’s almost like you’ve hit the diff lock button,” he affirmed. “You get that instant traction at the back and, once you don’t need it, it backs off. It’s such a difference; it’s unstoppable. You point it at anything and it walks over it like the terrain is concrete.

“I haven’t had it in any real steep terrain; although, we did the CREB Track and went up to Cape Melville in October last year and nothing really bothered it. It’s sort of cheating a bit; there’s no real challenge when driving it. I would rather be driving my little 1943 Jeep, to be honest. If you’re loading it up with gear and going somewhere a couple of thousand kays away, though, it’s not a bad way to travel!”

“I haven’t had it in any real steep terrain; although, we did the CREB Track and went up to Cape Melville in October last year and nothing really bothered it. It’s sort of cheating a bit; there’s no real challenge when driving it. I would rather be driving my little 1943 Jeep, to be honest. If you’re loading it up with gear and going somewhere a couple of thousand kays away, though, it’s not a bad way to travel!”

JMACX SOLUTIONS

This Cruiser is not a one-trick rig. As well as that awesome drivetrain, it has been further modified with an AEV-sourced GVM upgrade (it is now certified for 4500kg) and had a custom canopy fitted from Outback Customs, based out of Caboolture, Queensland. This set-up comprises two removable canopies (the front one doubles as Brad’s sleeper cab).

Reflecting Brad’s personal touring preference, there are minimal permanent fixtures in the canopies; only the fridge/freezer (with MSA Drop-Down slide) and a few other items are what he considers must-stay items. This allows the two cargo spaces to be super versatile – a must in Brad’s book when it comes to a touring vehicle.

Reflecting Brad’s personal touring preference, there are minimal permanent fixtures in the canopies; only the fridge/freezer (with MSA Drop-Down slide) and a few other items are what he considers must-stay items. This allows the two cargo spaces to be super versatile – a must in Brad’s book when it comes to a touring vehicle.

“I don’t really like having the kitchen permanently in them (touring vehicles),” Brad said. “I think you need that space to be a bit more flexible. Obviously the fridge has got to be in there, but we usually just use hard boxes, and when we pull up to camp just pull everything out, throw it on the ground and then set up a table. Then you can cook wherever you want to cook and you’re not relying on being near the vehicle. And then if I want to do a delivery anywhere – especially remote – I can just fill that whole back area up with MAXTRAX. So it’s just a flexible space more than anything.”

That theme of flexibility was also the reason for Brad specifying the canopies as removable. “We can take both those canopies off,” he said. “So we can lift them off and just use the tray. The tray is about three-and-a-bit metres long.”

That theme of flexibility was also the reason for Brad specifying the canopies as removable. “We can take both those canopies off,” he said. “So we can lift them off and just use the tray. The tray is about three-and-a-bit metres long.”

This tray length also means Brad can load up any of his toys when the canopies are removed. And, by toys, we’re talking a Polaris ATV and that 1943 Jeep Willys.

As well as the sleeper cab, the canopy is set-up with a Backtrax Ascent Pro rooftop tent atop a Rhino-Rack roof rack. This hard-roofed unit is operated via remote control (once you open a couple of exterior latches) and Brad rates the Ascent Pro highly, noting how quick set-up and close-down is, again reflecting his ethos of keeping hassles to a minimum when touring.

Speaking of hassles, the Cruiser’s turning circle is tighter than expected. “The full rig measures about seven metres all-up,” Brad said. “The turning circle is surprisingly good for something that size. I haven’t measured it, but you can sort of do a pretty quick turnaround – except on a narrow track where you’ve got to do a 48,000-point turn to turn around. But, yeah, for beach and desert work, which is what I have mainly built it for, it is perfect. You don’t really have to worry about your turning circle out there.”

Speaking of hassles, the Cruiser’s turning circle is tighter than expected. “The full rig measures about seven metres all-up,” Brad said. “The turning circle is surprisingly good for something that size. I haven’t measured it, but you can sort of do a pretty quick turnaround – except on a narrow track where you’ve got to do a 48,000-point turn to turn around. But, yeah, for beach and desert work, which is what I have mainly built it for, it is perfect. You don’t really have to worry about your turning circle out there.”

THE TRUE APPEAL

One thing that’s quite noticeable – or unnoticeable, as it may be – is that, besides the rooftop tent, there is a distinct lack of additional gear up on the roof of the Cruiser.

Another part of Brad’s ethos when creating this mega tourer was to keep it self-contained, self-sufficient and as frugal on fuel as a seven-metre-long 6WD Land Cruiser can be. This meant fitment of the two spare wheels to the rear of the custom tray, to minimise wind-resistance, as well as a 250-litre Long Ranger fuel tank on top of the stock 138-litre jobbie, to keep the Steinbauer-chipped TTDV8 humming.

Another part of Brad’s ethos when creating this mega tourer was to keep it self-contained, self-sufficient and as frugal on fuel as a seven-metre-long 6WD Land Cruiser can be. This meant fitment of the two spare wheels to the rear of the custom tray, to minimise wind-resistance, as well as a 250-litre Long Ranger fuel tank on top of the stock 138-litre jobbie, to keep the Steinbauer-chipped TTDV8 humming.

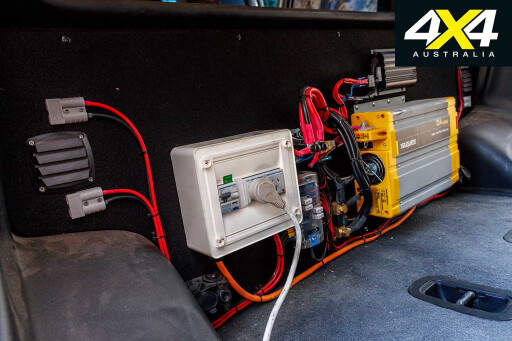

Adding to the remote-area readiness is a schmick Redarc solar power set-up, with BC/DC and an inverter sitting in behind the passenger seats ensuring there’s plenty of juice flowing to the dual-battery set-up – the lithium-ion batteries sit inside custom boxes set into the wheel arches either side of the cab.

All of this gear means Brad and his fellow travellers can disappear into the desert for weeks on end. “We do at least one or two trips a year, where we go away for three or four weeks or more. The fact you can just carry everything in that one vehicle, and you’re not going to have a heap of stuff piled on the roof rack or have to tow a trailer, it just makes it easy,” he said.

All of this gear means Brad and his fellow travellers can disappear into the desert for weeks on end. “We do at least one or two trips a year, where we go away for three or four weeks or more. The fact you can just carry everything in that one vehicle, and you’re not going to have a heap of stuff piled on the roof rack or have to tow a trailer, it just makes it easy,” he said.

Finishing off the vehicle is some exemplary ARB bar-work, Goodyear Wrangler (with Kevlar) MT/R LT285/70R17 rubber wrapped around ROH alloy wheels, and some comfy Recaro seats in the cabin. These, Brad reckons, top off the Cruiser’s comfort levels.

“It’s a pretty comfortable ride as it is, but the Recaros make it even better. Like I said, we took it to Cape Melville in October and it was only a short, two-week trip, so we did around five- to six-thousand kays and you can sit behind the wheel all day and still be comfortable," he added.

Getting this Cruiser on the tracks hasn’t been a short journey for Brad. He estimates that, between the AEV work, the custom tray and canopy build, and chopping off the back, it took around five months. Still, that’s not too bad for the end result: a purpose-built, self-sufficient, super tough outback touring vehicle that will definitely get you to places few have been. And then get you back again so you can brag about your adventure with your mates over some cold bevvies.

Getting this Cruiser on the tracks hasn’t been a short journey for Brad. He estimates that, between the AEV work, the custom tray and canopy build, and chopping off the back, it took around five months. Still, that’s not too bad for the end result: a purpose-built, self-sufficient, super tough outback touring vehicle that will definitely get you to places few have been. And then get you back again so you can brag about your adventure with your mates over some cold bevvies.

That has to be a good thing, don’t you think?

In Detail

1 - Light Bar

The light bar slots in between the Rhino-Rack and the roof, and it’s topped off with a set of MAXTRAX.

The light bar slots in between the Rhino-Rack and the roof, and it’s topped off with a set of MAXTRAX.

2 - Batteries

The area in the cab’s rear wheel arches is now devoted to housing lithium-ion batteries each side.

The area in the cab’s rear wheel arches is now devoted to housing lithium-ion batteries each side.

3 - Rear Winch

A Superwinch is neatly concealed at the rear of the custom tray, ready to deploy at a moment’s notice.

A Superwinch is neatly concealed at the rear of the custom tray, ready to deploy at a moment’s notice.

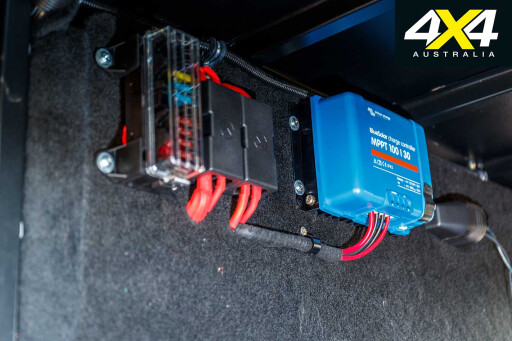

4 - Redarc Solar

The BlueSolar charge controller, of the Redarc solar power system, feeds the dual-battery set-up.

The BlueSolar charge controller, of the Redarc solar power system, feeds the dual-battery set-up.

5 - Rooftop Tent

Apart from the Rhino racks, the biggest piece of kit on the roof is the Backtrax Ascent Pro rooftop tent.

Apart from the Rhino racks, the biggest piece of kit on the roof is the Backtrax Ascent Pro rooftop tent.

6 - ARB Bar Work

Exemplary ARB kit has been plastered across the 6x6, including the bullbar, side rails and side steps.

Exemplary ARB kit has been plastered across the 6x6, including the bullbar, side rails and side steps.

COMMENTS