THIS video almost needs to be accompanied by a ‘not safe for work’ warning, because the gear Plazmaman has crafted for the Carnage MX5.7 project is straight-up car porn.

Plazmaman’s drool-worthy billet LS intake manifolds adorn such cars as Adam Rogash’s seven-second NOSHOW ClubSport, Nathan Farrugia’s world record-holding six-second Mazda RX-3, and the world’s fastest Cadillac CTS-V. Now we have our very own, along with a set of custom-engraved Carnage rocker covers.

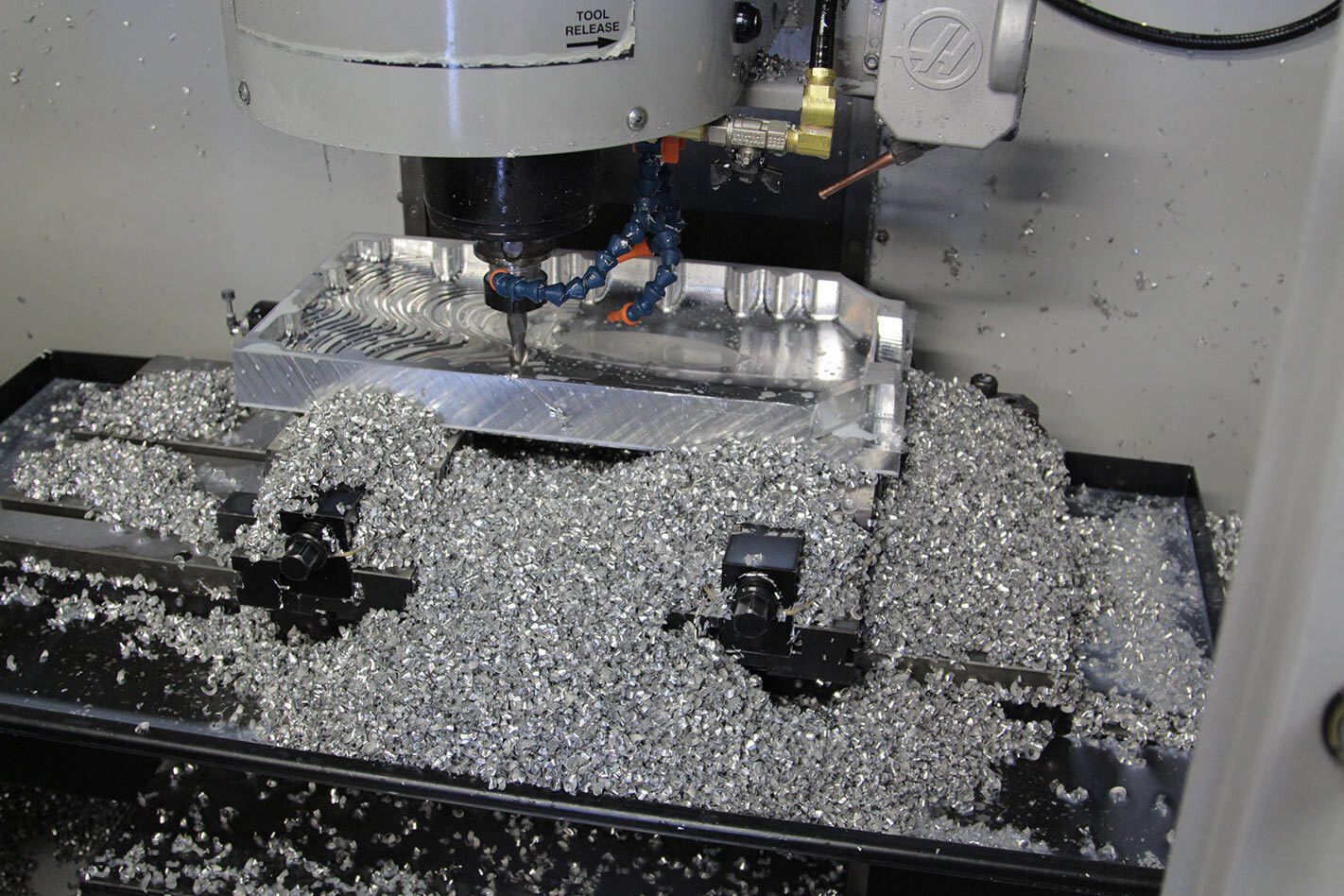

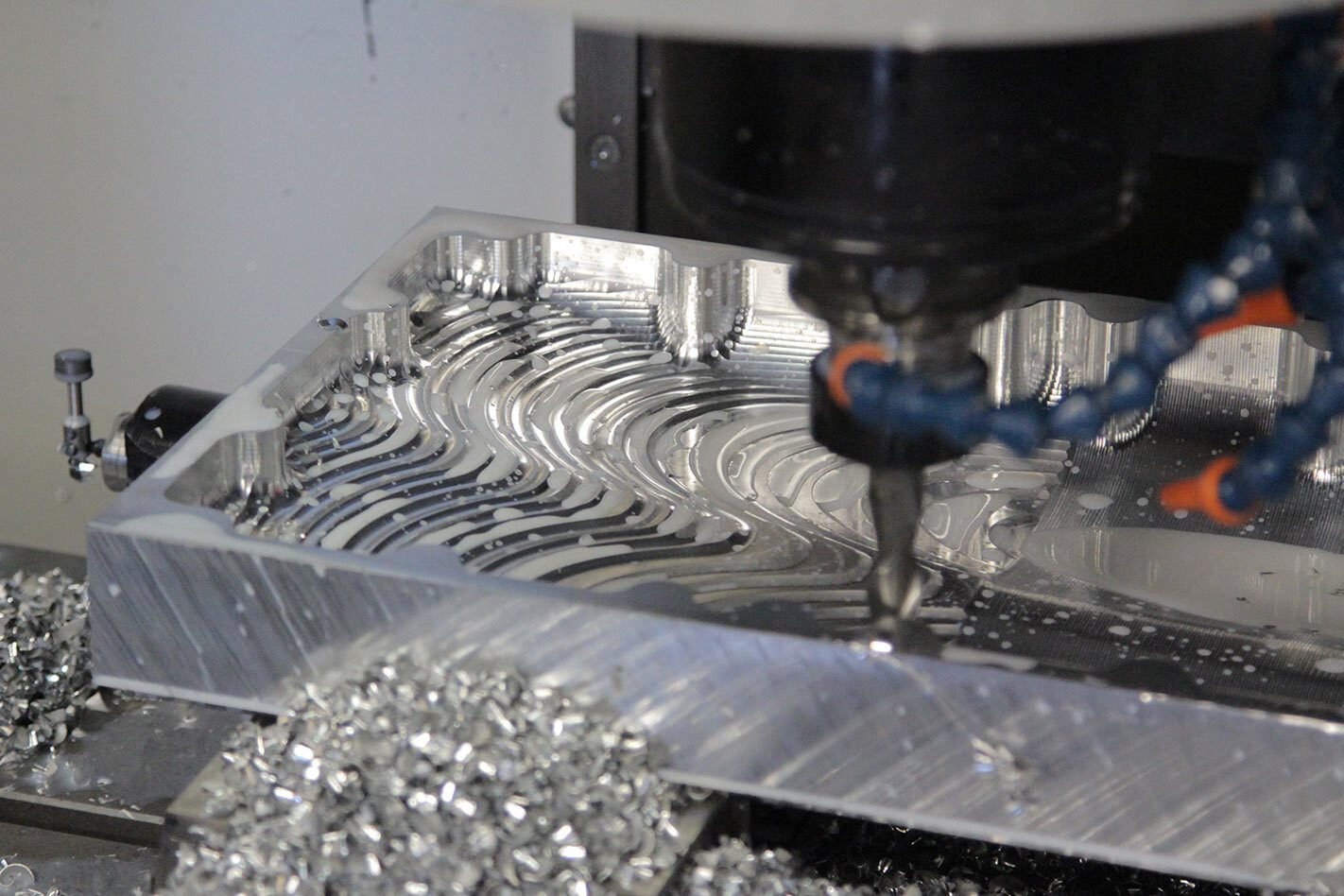

We cruised out to Plazmaman’s Western Sydney workshop to watch and learn as head machinist Matt Ramsay (son of blower guru Jeff Ramsay and pilot of the oh-so-cool eight-second Brumby FJ ute) put the CNC machines through their paces.

He also spoke to us about the products themselves, and the machining process.

Matt, talk us through the parts that Plazmaman has machined up for the Carnage MX5.7.

Matt, talk us through the parts that Plazmaman has machined up for the Carnage MX5.7.

We’ve machined up a full billet LS intake manifold, consisting of four major parts: the plenum valley, plenum lid and a couple of sets of runners. We also did a custom set of rocker covers with the Carnage logo in them. We do manifolds to suit every style of LS head, including the LS1 cathedral-port, LS3 rectangle-port, and the LS7 raised rectangle-port. They come as a full bolt-on manifold including fuel rails and a throttlebody adaptor if you’re running a standard drive-by-wire throttlebody. We also sell a billet throttlebody, which is a cable-style unit, with an adaptor to suit that. So it’s a full bolt-on kit including a billet valley cover. The manifolds are also quite easy to disassemble, and a lot of people comment that it’s easy to take the lid off and port-match the runners, because there are a million different types of heads out there. Our LS3 and LS7 manifolds are also available with twin side-by-side injectors, and we’ve sold a few to guys in the States running in Drag Week who will have one injector per cylinder set up for pump fuel or E85, and a second injector set up for methanol. It’s all configured in the ECU; they just flick over to the methanol tune-up and go racing.

What sort of raw material do you start with, and what’s involved in the machining process to make one of these manifolds?

What sort of raw material do you start with, and what’s involved in the machining process to make one of these manifolds?

We start with some raw blocks of 6061 aluminium; probably about 90-100kg of billet for a full manifold. All that is machined down to about 12kg at the end. A lot of the work has gone into the design process, and that’s where the majority of the hours have been in this project. Now that I’ve spent the time toolpathing and getting everything correct, there’s probably about 18-20 hours’ worth of total machine time to go from the raw rectangular blocks to the finished part.

The custom engraving on the rocker covers came up great. What’s involved in that process?

The custom engraving on the rocker covers came up great. What’s involved in that process?

We get the logo off the customer, who in this case was Scotty, though we’ve actually done a lot of custom engraving for a lot of customers. All I require is a CAD file that I can open in my Mastercam program, then I import it in and lay it over the top of the 3D model of the rocker covers, and we centralise it or put it where we want it. Then it’s quite a simple toolpath to create to engrave it onto the top of the rocker cover. Because we’ve already machined them, it’s easy for the covers to go straight back onto the same jig that we machined them on. It’s an easy set-up.

How are the products finished?

We offer a black anodise and what they call a clear anodise, which maintains the look of the raw alloy. The manifold lids and rocker covers are engraved after that process so the engraving stands out, especially when they’re finished in black. The anodising helps protect against corrosion and stops fingerprints and general dirt and contaminants getting on the products.

Comments