THE rise in popularity for race-and-drive events like Hot Rod Drag Week, Rocky Mountain Race Week and our own Drag Challenge has thrown a new level of complexity into building street cars. It truly is a wonder of modern engineering to put together an engine combo that can make four-digit power figures to run numbers at the strip but also pack good on-road manners and rock-solid reliability.

Platforms like the GM LS, Ford Barra and Coyote, and Chrysler’s new-gen Hellcat Hemi make this task much easier. This is why Brad Lowe and the crew from Warhorse Inc in Rutherford, NSW chose a late-model GM small-block as the heart for their VL Commodore gunning for eights.

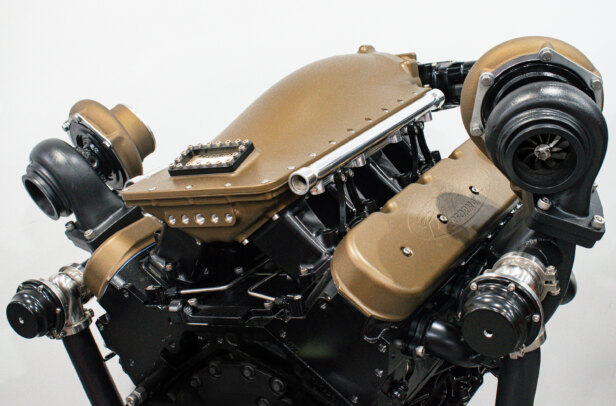

Starting with a Gen IV 6.0-litre LY6 iron block, engine builder Chris Sheppard put together a stout foundation using Wiseco BoostLine rods and CP Bullet pistons (with upgraded pins), swinging off a brand-new LSA forged crank. This adds up to approximately 9.8:1 comp, as the combo will run flex-fuel so it can race on E85 and cruise on 98 PULP on the highway.

The heads are factory LS3 #821 castings with a Higgins CNC-port job in them, fitted out with Brian Tooley Racing’s new shaft-mount rockers and Manton pushrods, which are pushing Isky tie-bar lifters. Under the lifters is a Crow hydraulic-roller womp-stick running 237/[email protected], with .600 lift and 115 degrees lobe separation angle.

A fat 88mm Garrett GTX55 snail is mounted on KillaBoost-made manifolds, with a 60mm Turbosmart ProGate attempting to keep a lid on the boost. A Haltech Elite 2500 ECU will control it all.

Shaun’s Custom Alloy provided the intake manifold, billet valley plate and rocker covers, while an MMS pointer makes checking timing a snack, and an Aeroflow four-port steam kit bleeds hot spots out of the iron LS. Behind the dual-row Rollmaster timing chain is a Melling oil pump, while an Aeroflow sump sports a modified windage tray and baffles.

“These LS engines are a great base and really easy to make power from, if you put them together correctly,” explains Warhorse Inc engine builder Chris Sheppard. “Some people think you can get 1000hp out of a stock bottom end, but I just don’t know how long that will last if you actually use it.”

Ultimately we’ll be seeing more of these types of combos soon, as Warhorse Inc is gearing up to build more fast cars and stout donks.

“We do everything, including race prep, engine building, machining services, a dyno cell and other fab work,” Brad Lowe explains. “We want to focus on motorsport because we all have a background in that. We have another LS combo here that we’ll push towards 2000hp.”

This particular engine will go into a VL owned by one of the Warhorse crew, Matt Butler. “Matt bought the car stock and has built it up over time, so we haven’t ever had a combo like this in it before,” says Brad. “We’ll bring it to Drag Challenge and are aiming to make 1500-1600hp with it, so the goal for the VL is mid-eights on a 275 tyre.”

BREATHE IN

THE Shaun’s Custom Alloy sheet-metal manifold features billet runners with a fabricated plenum and is fronted by a Plazmaman cable throttlebody. It will be loaded with Siemens 2400cc injectors to keep ample go-juice up to the engine.

WARHORSE INC,

RUTHERFORD, NSW

warhorseinc.com.au

Comments