Tony Di Biagio from TDR Engines would agree, as he recently pulled the trigger on a spicy small-block Ford for his XY Fairmont streeter.

First published in the March 2022 issue of Street Machine

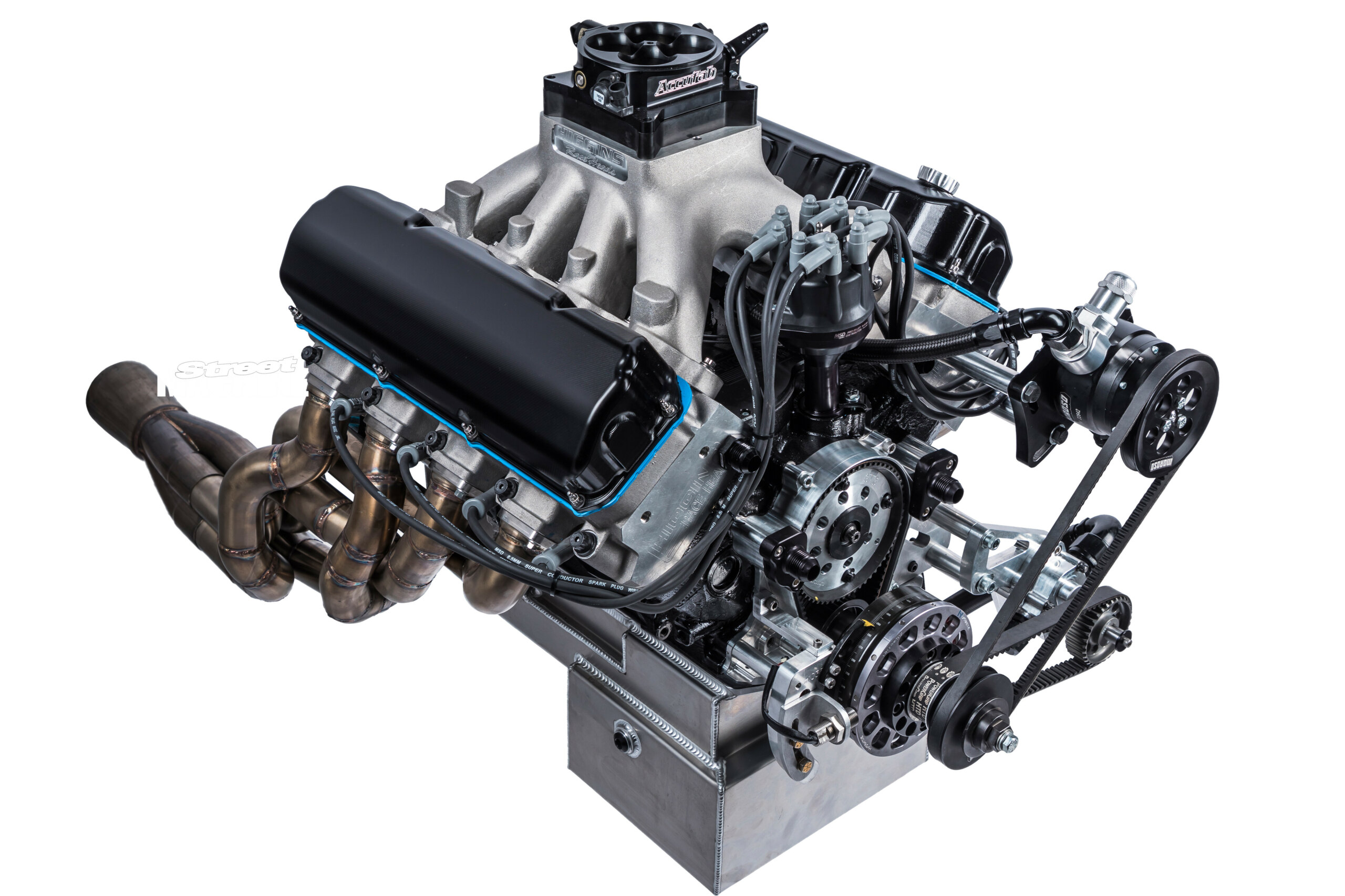

The 451ci Clevor makes 860hp on pump fuel and just over 905hp on 109 drum fun, at 8000rpm. It is based on a Dart Iron Eagle 9.5-deck-height block using a 4.1-inch-stroke Callies Magnum crank, Callies Ultra steel rods and 4.185-inch-bore custom CP pistons.

“The compression is in the high 12s or low 13s,” Tony says. “With the cam in it, I was expecting more cylinder pressure, but on the first dyno pull it did 860hp on pump fuel with only 21 degrees timing!”

Tony specced his Dart block with a 55mm cam tunnel and had Bullet Racing Cams grind him up an angry solid-roller, paired with BAM .937 lifters with bronze bores. Because Tony has years of experience building engines, he is keeping the exact specs quiet for the time being. “There is a ballpark lift and duration for what you need to run these kinds of horsepower numbers,” he explains. “We’re taking into account head flow and cross-sectional areas; there is so much involved to get a great result.”

Up top are a pair of Higgins Race Heads castings, based around the Cleveland design and capable of flowing up to 420cfm. Rocking titanium valves, PSI heavy-duty double valve springs and custom Jet Engineering 7 /16-inch pushrods, the heads are capable of making huge numbers, especially when partnered with the towering Higgins single-plane intake standing tall above the valley.

With a stint at Street Machine Drag Challenge on the cards, Tony realised he needed a way of reducing the valvetrain stress from the big solid-roller cam, so he’s got two sets of rockers for the Clevor, depending on where it is being driven. “I have T&D shaft-mount 1.9-ratio rockers for the track, and I got T&D to make me a custom set of 1.5s for the street to get the open pressure down and save on the lifters and valvetrain,” he explains.

The front of the engine has a lot going on, with the Xceldyne belt-drive sitting above the Hyperaktive 12-magnet crank trigger, which lives next to the Peterson external oil pump. As the stout SBF will run Holley EFI, Tony has replaced the distributor’s individual coil packs with MSD cam sync in order to run sequential injection and individual cylinder timing for finer control of the high-revving little-block.

Exterior details are finished off by a gated alloy wet sump from Toca Performance, custom two-inch headers and a Moroso vacuum pump to improve ring sealing.

“It’s good for a start,” Tony laughs. “The plan is to put nitrous on this engine next year, but I want to push the aspirated set-up as far as I can and get a lot of the shakedown done. I have to change the cam and piston design for nitrous, as I want to put 500-600hp worth of gas down it.”

INJECTION SITE

Tony ran the engine on the dyno using a carburettor to get his numbers. Once that was done, he pulled the intake manifold and drilled out the pedestals for eight 1000cc Bosch injectors controlled by a Holley Dominator ECU.

TDR Engines

North Geelong,

Victoria

Comments