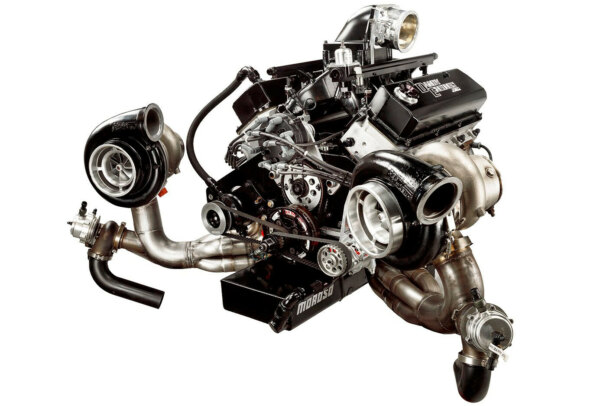

MAKING big power out of small cubes is one thing, but Steve Makarios also has to make his engines live for thousands of kilometres’ worth of circuit racing. The bloke behind Synergy Race Engines has spent years screwing together killer mills for the Touring Car Masters race category, like this 351 Windsor for the ’69 Mustang driven by Cam Mason.

From the March 2021 issue of Street Machine. Photos: Shaun Tanner

“There’s a lot of regulations we have to adhere to,” Steve explains. “For a 351 Windsor, we have to use a Dart 195cc head specifically; we can’t have a bigger head than that, but we can CNC-port them. The intake manifold is height-controlled, so we can’t have lots of spacers. We’re rev-limited to 7500rpm through the ignition box, we all have to run 100-octane fuel, and we’re allowed to push capacity 60thou up on what the car is legally allowed to run.”

For Mustangs, engine choice comes down to a 351 Windsor or 302 Boss, and while the Cleveland heads are known for making bulk power, Steve prefers the Windsor. “Under 7500rpm, the Windsor is a better engine, because it has more torque lower in the rpm range,” he says.

This small-block Ford is 30thou-over and runs a nominal displacement of 357ci thanks to a Callies Magnum XL crank custom-made to Synergy’s specs, with Callies Ultra I-beam rods and CP X-Forging 12.5:1-compression slugs. “I like having the heavier crank and rods in the engine to keep them robust,” Steve says. “One of our engines did five seasons, though the rod bolts and pistons get changed about every two seasons.”

Synergy gets its solid-roller cams custom-made by COMP in the USA, while the lifters are Jesel keyway units. “Cam specs are free, but you need to be realistic with lift and duration, because these engines have to do 5000 racing kilometres or more,” Steve explains. “We run T&D shaft-mount rockers and keep the ratios pretty standard, as we’re not chasing a lot of lift due to them being endurance engines.”

The oil system is a Dailey Engineering dry sump featuring a custom-made pan and six-stage pump, while the MSD billet dizzy is another control feature due to teams not being allowed to run crank triggers.

“The cars hold 10-12 litres of oil in a tank in the boot, or in the car in a box,” Steve says. “We have been using Mobil 1 0W-50, which is a high-zinc racing oil the NASCAR guys use. We have found a lot of power with bearing clearances, oils and oil pressure; too much pressure can create too much drag internally. These engines create a bit of crankcase vacuum, which helps give them another 8-10hp.

“We did our first engine around 2012-13, which made 640hp, and we’ve built about 16 TCM engines since then,” Steve continues. “We dyno-tested the last one and it made 738hp and 540lb-ft. We’ve done a lot of them, and we keep improving.”

CARB LOADING

TOURING Car Masters rules allow one 4150-pattern four-barrel carb. “We have a guy in the US who supplies us custom-made billet carbs,” Steve says. “They’re always perfect when we get them out of the box, but it’s always challenging tuning for the atmospheric conditions at each track, as the carburettor doesn’t tune itself. Water and oil temperatures are also very important, because if you get caught behind another car, the water and oil temps shoot up and it changes the tune.”

Synergy Race Engines,

Dandenong South,

Victoria

Comments