YOU have to admire a bloke that’s in it for the long run. A bloke that’s held on to his first car, purchased before he even got his driver’s licence, then rebuilt – several times – and improved upon it until it turns into a 1000hp-plus monster capable of eight-second timeslips. That’s the story of Nick Ierino’s HZ and it’s been a long and sometimes winding road, so we might as well start at the very beginning, back in 1992.

This article on Nick’s HZ Holden was first published in the June 2019 issue of Street Machine

The car has always been dark blue, although it did wear a white roof from the factory. It’s now painted Cobalt Blue, an EL Falcon hue

“I got it from a guy in Maddington, one owner, he worked for my old man in the Water Corporation,” Nick says. “It was Atlantis Blue with a white roof, venetian blinds, 202, column three-speed. The first thing I did was put a four-speed in it and then Dad drove it around for a year. I just looked at it every day and drove it up and down the driveway.”

For what must have been the longest year of Nick’s life, his dad had the HZ parked in the garage, but it got dusted off and parked out on the driveway for Nick’s 17th birthday: “I had my driver’s licence test booked in and when I got home it was there waiting; he must have known I was going to pass,” he recalls.

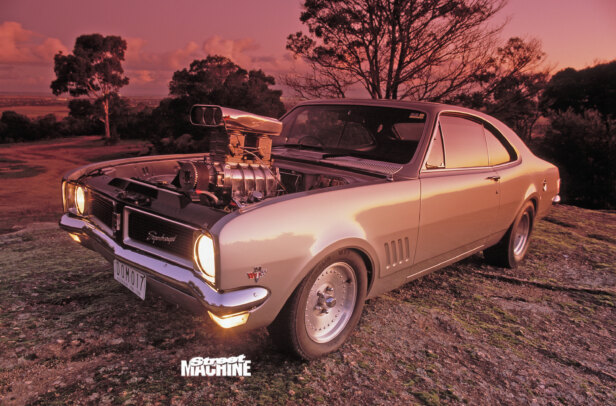

The reverse-cowl scoop hides all the spinning parts of the blower set-up, but those Quick Fuel 950 carbs sit up high and mighty

While the 202 and four-speed did the job initially, it wasn’t long before a V8 and fresh paintjob were on the cards. A fresh coat of VR ClubSport dark blue went on and a 308 was slotted into the engine bay in 1993, but a few short years later the car got another makeover.

“When I started my apprenticeship as a heavy-duty diesel mechanic we had a paint shop, and that’s when I painted it Ford Cobalt Blue,” Nick says. “It was pretty much a full resto; the front end came off, the chassis was painted black with blue pearl and I put a small-block Chev in it.”

This was a one-owner car when Nick first got it in 1992 with just 120,000km on the clock and next to no rust. That’s why he hasn’t cut it up to tub it

Nick enjoyed cruising the HZ with its fresh V8 rumble for a number of years before family commitments and being a grown-up took hold and the car was parked up between 2000 and 2007. But once Nick pulled the covers off, things started to ramp up – a lot: “I put a little Weiand 177 blower on it and it was running 9.80s and still cruising the streets.” Admittedly, that was on methanol, but a switch back to pump fuel still had the HZ running 10.40s consistently. The little blower worked a treat getting the car out of the hole, while the top end was handled by a very serious camshaft.

The car had no problems hooking up, even though it’s not tubbed. Nick did some small tweaks to the rear wheelarch to fit 30-inch rubber under it. “I’ve cut about 30mm at the front of the wheelarch,” he says. “When I raced it with the 30-inch tyre, as it grew, it touched the wheelarch, so we took a vee out of it and folded it back in.”

That’s not the only reason the car leaves hard and straight with both front wheels off the ground. There’s also a custom anti-roll bar out the back fabricated by Mike Crossing at Race On Customs, as well as Competition Engineering shocks front and rear. There are also tubular arms on the front by James Cloke and CRS tubular control arms out back.

In 2011 another rebuild began – that’s number three for those keeping count – following a slight altercation with a barrier in the Snakepit at Motorvation. “We gutted it to nothing – bare metal,” Nick says. “The chassis was sandblasted and it was a five-year build. That’s when I switched to the GTS trim with the interior, nosecone and guards.”

A quartet of gauges have been installed on the back of the cowl scoop – a very neat and tidy solution

With the car stripped back to bare metal, there were no surprises at all; after all, it was a one-owner car when Nick got it and had been well looked after under his ownership. Having a best mate as a panel beater is always helpful, even when they’ve retired from the job, so Nick took the body to Mario Giovinazzo’s shed where another coat of Cobalt Blue was laid on. It’s even better when your brother owns his own spray painting business: “My brother Marc painted the front end and then we flow-coated the whole car in the booth at his work. He owns Ierino’s Kustom Coatings in Malaga.”

While a lot of effort went into making the car look nice, it’s in the engine bay that Nick really went to town. While most blokes would have opted for a nice 8/71 on top of their tough small-block, that would have been way too easy. Instead, on top of a very tough 406-cube donk based around a Dart Iron Eagle block and AFR heads, Nick bolted on a 3.4-litre Whipple blower. With advice from Sandro Principe from SCM Race Engines & Performance, Nick screwed the engine together before heading down to the dyno at Geoff Chaisty’s C&R Motorsport Developments.

The 406 is based on a Dart Iron Eagle block and Pro-Filer 176X heads. On a diet of methanol with just 14psi of boost, it made 997hp at the tyres at 7100rpm. Stout!

“Sandro, Gonzo [Simon Travaglini from AllFast Torque Converters] and I put it on the dyno with the single carb. We knew these Whipple blowers don’t lean over at high rpm and we kept putting more fuel in it and we couldn’t get it right, the AFRs were shocking. But at 5500rpm it made 960hp. Geoff was losing it, he said: ‘This thing’s an animal, it will hit the limiter instantly – this is for a boat!’” That was with a single 1150cfm Dominator, and they couldn’t get enough fuel to the engine, so Nick had to figure out a solution, as he was adamant about making it work.

“I went back to Whipple; they did a twin-carb set-up but it was for Edelbrock carbs, which were too close together, so I bought their 4500 base adapter and got a Weiand 4150 twin-carb adapter, bolted them together and got them welded up. Then I started hogging the arse out of it; it took me about a week.”

On the first pull, the rear cylinders were a bit average, but Yella Terra made a deflector that bolts underneath the blower in the manifold. It deflects the boost to the back cylinders and works well

After getting the adapter milled to ensure it was flat and true, Nick then took his home-made masterpiece to Sandro: “He said: ‘Who did that?’ I said: ‘It was me.’ He said: ‘F**k off, Chich, this is gonna work!’”

And work it did – with the new adapter and twin 950 carbs it went straight to 1060hp, but not everything went to plan.

The stock cream interior was replaced with full HZ GTS trim and dash. The six-point ’cage by Race On Customs is a necessity when you’re running in the nines or quicker

“That’s when I dropped a valve on the AFR head and lunched the engine, and I built another engine with the Pro-Filer 176X heads,” Nick says. “We never put it on the engine dyno; we know we’ve got it right, it’s got a heap of fuel and we’re safe as houses. Even Gonzo said: ‘Chich, that’s gonna piss.’”

It will piss to the tune of 997hp at the tyres, and while Nick hasn’t hit the track yet, the combo should be good for 8.80s. He better hurry up and run some numbers though, because his kids are keen for him to get the car back to a more streetable configuration. “Now my boys are getting older, I’d love to cruise the street again with it, so I might build a tough aspo deal. This combo’s really good; it’s cost me a lot, but it works – and it’s a one-off.”

NICK IERINO

1978 HZ HOLDEN

Paint: Cobalt Blue

DONK

Type: 406ci Chev

Inlet: Weiand raised port

Carb: Twin 950cfm Quick Fuel

Blower: Whipple 3.4L

Heads: Pro-Filer 176X 235cc

Valves: 2.125in (in), 1.600in (ex)

Cam: [email protected]

Pistons: Manley forged 10.5:1

Crank: Manley forged

Conrods: Manley H-beam

Radiator: Brown’s aluminium

Exhaust: Di Filippo 2in primaries, twin 3.5in

Ignition: MSD 7AL-2, MSD distributor and leads

SHIFT

’Box: AllFast custom Powerglide

Converter: AllFast custom billet

Diff: 9in, Strange centre and billet support, 31-spline axles

BENEATH

Front end: Tubular wishbones, King springs

Rear end: Tubular control arms, anti-roll bar

Shocks: Competition Engineering

Steering: Standard

Brakes: Wilwood four-piston (f), drums (r)

ROLLING STOCK

Rims: Center Line Rev; 15×4 (f), 15×8.5 (r)

Rubber: 195/75/15 (f), 255/60R15 (r)

THANKS

Marco and Mario for the panel and paint; Sandro from SCM for engine combo and tuning; Simon at AllFast for the ’box and converter

Comments