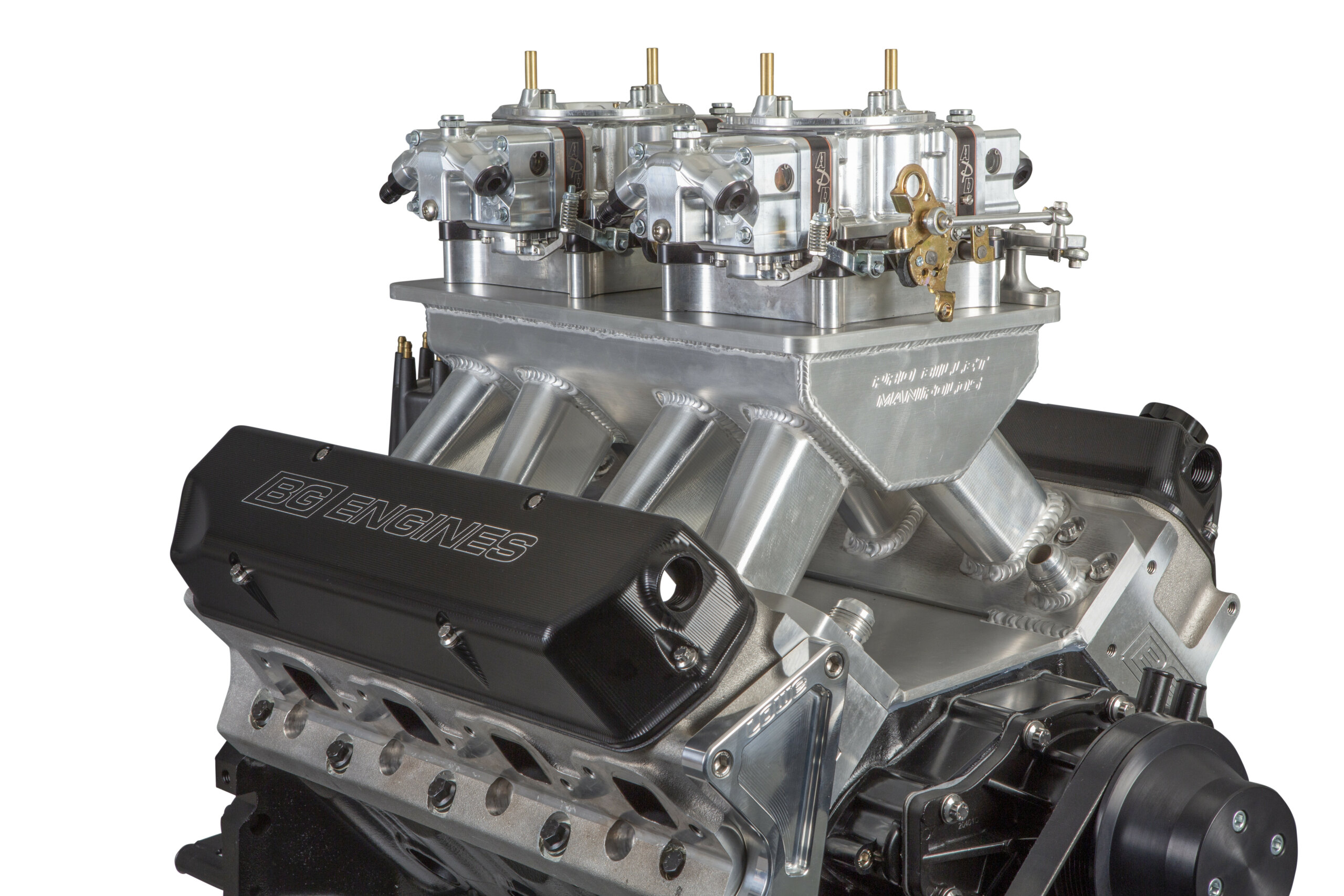

According to Damian Baker of BG Engines, the Iron Lion is still alive and kicking. “The Holden side of things is still extremely strong; at any given time we probably have six to 10 of them in the shop,” he explains. “This one in particular has a couple of really cool features.”

First published in the July 2021 issue of Street Machine

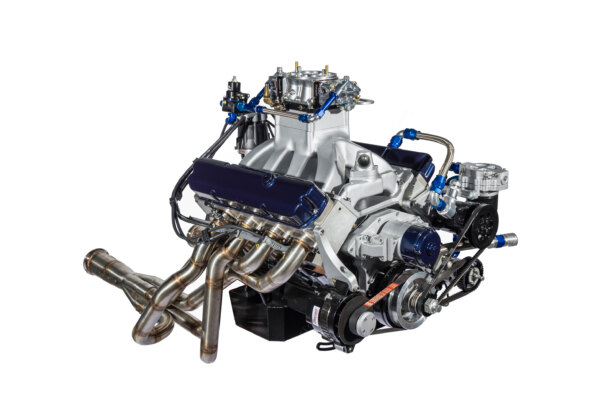

For starters, the block is a brand new VT roller item that had never fired a shot, meaning that BG had the luxury of retaining the standard 4.000in bore. With a Scat steel crank, Scat I-beam rods and SRP forged flat-top pistons, the displacement ends up at 350ci, rather than the 355ci more commonly associated with stroked and bored Holden V8s. Because the brief called for an engine suitable for regular street use with a manual gearbox, compression was limited to a modest, pump fuel-friendly 11.7:1.

The lads at BG Engines have literal decades of experience with Holden V8s, and so they tended to the usual weak points with oiling system modifications, a small-block Chev rubber rear mains seal conversion, and one of their in-house CNC-machined billet mains girdles, which is compatible with the baffled Aeroflow pan.

The alloy heads are Yella Terra castings, which were ordered blank. The BG team selected suitable valve sizes for the application before cutting the seats and hand-blending the ports to suit. The heads are decked out with Yella Terra Platinum shaft roller rockers, COMP Cams valve springs and steel retainers, with Crow moly pushrods and BAM diamond-coated bushed lifters also used.

The camshaft is a mechanical roller, and was specced according to the owner’s desire to make decent grunt while retaining suitable road manners. It sports 249/255 degrees duration at .050 lift on 108-degree centres, and 0.620in of total valve lift. Like all solid-cammed Holden V8s, it sounds properly angry.

“This is a street cruiser with a bit of grunt, but the customer wanted some bling in the form of one of our in-house tunnel rams,” Damian grins. “The car itself is an absolutely stunning VK being built by the guys at Image Conversions, and the motor had to match.”

The beauty of your engine builder also fabricating your inlet manifold is that variables such as plenum volume and runner length can be properly optimised to suit the application.

“The engine is only 350ci, which is quite small in today’s terms,” Damian says. “We made the CNC-machined runners quite long, which helps with driveability, especially with it being a manual. You don’t have the luxury of a slippery converter helping it come on song, so we had to get it right. The manifold comes into play a lot with that; I’ll ask a customer 30-odd questions when we come to designing them. And all the experience we now have doing lots of street driving at Street Machine Drag Challenge has taught us how to tailor these set-ups to be driveable.”

But it still makes plenty of stonk, right? Yep, 627hp at 7400rpm, which is a very healthy number indeed for a pump-fuel, 350ci all-motor Holden.

“We tried not to get off track with this engine and wreck the driveability; maintaining that was really important,” says Damian. “It made 500ft-lb of torque; they drove the car around the block the other day, and I’m told it just wants to get the tyres off all the time!”

HEY GOOD-LOOKIN’

SEXY billet hardware abounds, including the Pro Billet tunnel ram, APD carbs, Shaun’s Custom Alloy rocker covers, timing cover, belt drive system, CVR alternator and Lowe Fabrications alternator bracket. But how’s this for going to extremes to ensure the engine looks the part? “A lot of race engines require the inlet manifold to be removed frequently for maintenance, so we often machine O-ring grooves into the inlet faces of the cylinder heads to make that quicker and easier,” says Damian. “In this case it was more for looks. The runners on the tunnel ram are CNC-machined to the shape of the ports, so if we were to use factory-style inlet manifold gaskets, it’d look pretty ugly. By using O-rings, we can do away with the manifold gaskets for a much cleaner look.”

Comments