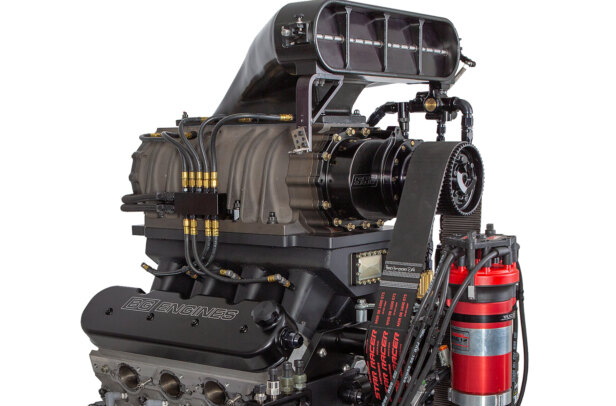

Handling the stresses of running wide open on a pad for a minute straight is no mean feat for an engine, which explains why we’ve seen burnout-car donks morph into wild, purpose-built creations. The tower of power you see here is a good example. What hides inside this conventional-looking big-block Chev is plenty of smarts that Damian Baker from BG Engines has learned through years of hard work.

“It runs a 9.8in-deck-height Dart Big M block with a 4.5in bore and a 4in-stroke Callies Magnum crank, for 510ci,” says Damo. “It’s the same set-up as what is in [Rodney Waters’s] KRANKY HQ, and the reason for it is to keep piston speed down. You want cubes to make grunt, but this style slows the piston down and holds it in the bore better.”

Along with the dual-keyway-equipped crank, there are Callies rods and 10:1-comp CP slugs, while the Jesel belt drive turns the BG-spec solid-roller power stick. Thumping out 260/274° at 0.050 on a 112° LSA and boasting 700thou lift, it shoves top-shelf BAM lifters coated in diamond-like carbon and Jet 3/8in pushrods.

Up top, a GORR carbonfibre hat houses the BG-developed mechanically injected fuel system, spraying the methanol provided by a 110 Enderle pump. Ignition is handled by an MSD 8+ box, while a four-stage Peterson dry-sump system takes care of oil control.

“In burnout engines, we look at oil pressure and oil temperature,” Damo explains. “We run 105psi in this engine, but you need plenty of oil volume to combat the heat. These engines need 15 litres of oil, because oil temperature is the enemy when they’re on the limiter for a minute straight and they’re making this kind of power.”

Damo says another key to a good blown burnout engine is ensuring it can handle both temperature and pressure. “Going from cold to hot in a minute puts strain on these engines like nothing else; there aren’t many other forms of racing that puts the strain on the engine with no airflow,” he says. “Rather than running a traditional moly piston ring, we’ve fitted Total Seal Hellfire rings for better tolerance of the high cylinder pressure found in these engines. They can make upwards of 300psi in a cylinder at peak power, so the demand on the rings is much higher, and the steel Hellfire ring tolerates the heat much better.”

After running-in the rejigged fuel system on the flowbench, it was time to spin the angry mill up on BG’s in-house engine dyno. With the Blower Shop 8/71 pump pushing 14.1psi into the eight-litre monster, it made 971lb-ft@6100rpm and 1220hp@7300rpm.

“It is going into the SIKEST HJ ute, which is used predominantly for burnouts and Powercruise events,” says Damo. “It came to us hurt, but we were fortunate enough to re-sleeve two cylinders in this block to save it and fix the damaged chamber in the cylinder heads.”

We can’t wait to see SIKEST making clouds once more!

BG Engines

North Richmond, NSW

Comments