MATT Elliott has never done anything like this before. Growing up in New Zealand and now living in Papamoa on the North Island, Matt spent his younger years messing with Japanese beasties such as his Mazda RX3 and Mitsubishi Lancer Evo 2. There was also a Ford Escort Mk II, but he never played with the bigger toys – the muscle cars and V8s. Life moved on and he spent seven years in a company car. Then in 2007 Matt saw an ad for this 1979 Chevrolet C10 stepside pick-up.

This article was first published in the March 2014 issue of Street Machine

“When I was real young I always liked the look of the 1950s Ford F100s,” said Matt, now 37 and a sales manager for Bay Engineers Supplies. “I guess they were a bit rarer to find here, but the stepside C10 kinda resembles those trucks, so that’s what drew me to it.”

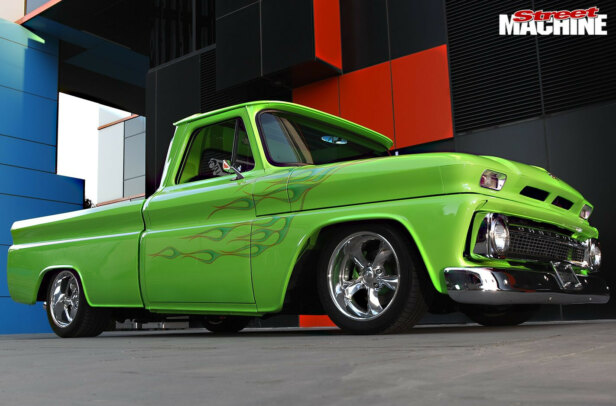

Like the engine bay, the theme with the body was to keep it smooth and clean. Door handles, gutter rails and wing mirrors were shaved, and the indicators were taken out of the front guards. Around the back, LED strips replaced the old bolt-on light buckets

Matt bought that C10, but apparently it didn’t look like the pick-up you see here. Sure it was orange, bagged, wore chunky rubber and, as Matt recalls, was “pretty tidy”, but some major changes were about to take place.

After driving the pick-up for five months, the original transmission packed it in. Matt replaced it with B&M Street and Strip Turbo 350 and then, half-way into 2008, the stock motor started to play up and Matt suspected he had cracks in the bores. So he ordered a 383 Chevy crate motor from the States.

Matt’s pick-up combines the best of minitrucking and hot rodding to achieve a clean, but streetable, ride. It’s just as home on the street as it is in the show hall

If told their new engine would take six months to be delivered, many blokes would push the pick-up into a corner and await the donk’s arrival. Not Matt. He used the next six months to turn a pick-up that was already “tidy” into something close to perfection, with a bit of help.

“It just so happens that a couple of my mates are really talented guys. Jason Sellars pretty much took care of all the chassis fabrication and the motor side of things,” Matt said. “Another mate, Nakija Klaus, said he’d help to do all the panel work.”

But Nakija’s help would go beyond just a bit of panel beating. He works at Rods By Reid (SM May 2013) – an internationally acclaimed hot rod building company – and has the type of vision and skill required to build world-class cars.

Both Matt and Nakija knew they needed a plan.

The existing chequer-plate tray was dumped in favour of curved sheet metal so smooth it looks like fibreglass. Hidden under the hump is the tank to the airbags, the fuel tank and battery. All can be accessed by push-down/pop-up magnetic trapdoors

“Nakija and I did the concept together. I guess I had a few different influences – a bit of hot rod, mini truck, some Japanese stuff. So Nakija did a drawing. We made it a mission to smooth everything off and do tubs in the engine bay to hide everything. So we pulled the motor out and got a little bit carried away.”

It started with the wiper motor being hidden in the cowling.

“Once you start doing stuff like this, you have to carry on – can’t have anything showing.”

While waiting for his ZZ 383 crate motor to be delivered from the US, Matt and his mate Nakija used the time to design and build a super-smooth engine bay that would hide the wiring and almost everything else apart from the engine itself. He wanted people to look under the bonnet and wonder how the engine actually worked

This is where Nakija’s skills with sheet metal would come into play. The heater is hidden, as is the power-steering pump, the radiator is fitted into its own compartment and the inner guards cover the chassis rails.

The ugly brake booster was dumped in favour of a Wilwood master cylinder and pedal box under the dash. Other accessories were mounted low and out of sight.

Having set this standard in the engine bay, Matt knew the treatment had to be extended to the rest of the pick-up. Nakija went to work on the body, shaving the door handles, the drip rails and the mirrors. He created a custom roll pan, the rear light buckets and strip LED tail-lights. He also made a new dash for the C10 using a single piece of sheet metal.

While this was happening, Jason – who has his own business, JS Engineering – was fabricating the headers and shaping up the brackets for the motor. The C10’s original chassis needed boxing, extra bracing was added and the four-link was tidied. When the crate motor arrived, Jason shaved down bolts and fitted it snuggly into the tubbed engine bay.

When Matt bought the pick-up, the tray was made from chequer-plate aluminium, with the air tanks bolted on top, but that was no longer going to match the pick-up’s new smooth look. Jason went to work making a drop tank and mounting points for the airbag tanks, all housed under the new curvaceous tray floor. Another mate, Cory Abbott, did the wiring and hid it all from view.

Matt’s mate Nakija created the custom dash out of sheet metal with Auto Meter gauges slotted into the hand-made fittings. The addition of black leather upholstery finished off the build, with Shaun from Action Canvas doing the trimming

It was now 2010 and, after the truck got its coat of tangerine pearl paint, it was finished. Hang on, nothing is ever finished, is it? In 2011, Matt came across a D1 Procharger and over the next few months it was added to the engine bay. That meant getting Nakija to remodel the tubs to keep the engine bay smooth and minimal.

“I wanted people to look in and be left trying to figure out how the engine worked; where are all the wires?”

Matt’s C10 is proof you can do a super high-quality build on a budget if you have a plan and friends who know what they’re doing – and willing to charge mates’ rates.

It may be a pristine work of art, but Matt drives it everywhere.

“I’ve done about 5000 miles in the last couple of years. People normally freak out when they see it cruising around, when they think it’s solely a show-based vehicle.”

MATTHEW ELLIOTT

1979 CHEVROLET C10 STEPSIDE PICK-UP

Colour: Tangerine Pearl

POWER

Engine: ZZ 383ci

Induction: Weiand Air Strike inlet

Blower: Procharger D1

Carby: Quickfuel 750cfm

Heads: Edelbrock

Camshaft: Hydraulic

Conrods: 5.7in ZZ 383 stock

Pistons: 9.0:1

Crank: Scat, one-piece forged

Oil Pump: Moroso high-volume

Fuel system: Aeromotive A1000 pump

Cooling: 16in fan in custom enclosure

Exhaust: 1 7/8 headers, 3in twin exhaust, Flow Master mufflers

SHIFT

Transmission: B&M Street Strip Turbo 350, external oil cooler

Converter: B&M 2500rpm

Diff: GM 12-bolt, Eaton Posi LSD, 3.43:1 gearing, Moser axles, custom one-piece tailshaft

UNDERNEATH

Suspension: Porterbuilt upper and lower control arms, increased castor with Slam Specialties RE-7 air bags (f); Ridetech triangulated four-link with Firestone air bags (r)

RIMS & RUBBER

Wheels: Intro Pentia 20×8.5 (f); 20×10 (r)Tyres: Nitto 255/35/30 (f); 275/40/30 (r)

THANKS

Nakija Klaus for the panel work, Jason Sellars for all fabrication work, Cory Abbott for the wiring and more, High Impact Paint and Willy Johnson for the paint and prep, Mothers Polish, Townsend Brotherz Racing, Nate at Porterbuilt, Shaun at Action Canvas and Bay Engineers Supplies

Comments