WHEN your streeters run 200mph on 275s and you want to step up into radial racing leagues, you need to be swinging a bigger bat to compete. But Frank Marchese and Dan Szabolics, along with Dan’s father Wally, aren’t going in blind with this ProCharged, 3500hp, billet Pro Line Racing Hemi.

The monster mill is housed in a 2004 Pontiac Firebird that has already proven itself in radial racing both here and in the USA. Frank is fettling it using all the experience gleaned from his years at Dandy Engines, in partnership with Dan and Wally, who have their own runs on the board having built killer cars like Dan’s twin-turbo 632ci HQ Monaro (SM, Dec ’19) and blown LX Torana (SM, April ’20). Frank, the 2018 Street Machine Drag Challenge champion, kicks the story off.

“Dan got the racing bug after running the HQ,” he says, “and after watching Joe Gauci run his Profab turbo car, he decided he wanted to go that fast. Then Grubby’s car came up as a roller.”

The Grubby to whom Frank refers is Sydney radial racer Matt Grubisa, and the car is the Firebird, which Dan added to his drool-worthy fleet. “Dan wasn’t a fan of the shape, but he asked me if it was a good car and I told him it was one of the best at the time,” Frank says. “We thought about going 481X and we bought one off Perry Bullivant, but then we started talking to Steve Petty about whether we’d go twin-turbo Stage IV 481X, or ProCharged Hemi. I get a lot of good help from my mentor Steve, and he’s pursued these ProCharged Hemi combos to get them to where they are today. Steve told me to try it, as he felt he had the combo sorted.”

Frank had a sit-down with Daniel and Wally and it was agreed that they’d go into this thing together, as partners.

“Wally really made this whole project go,” says Frank. “Until the ProCharger idea popped up, I wasn’t going to be a partner. But if I’m going to sell this package to a customer, I want to know what’s involved. We don’t use the customer as a guinea pig.”

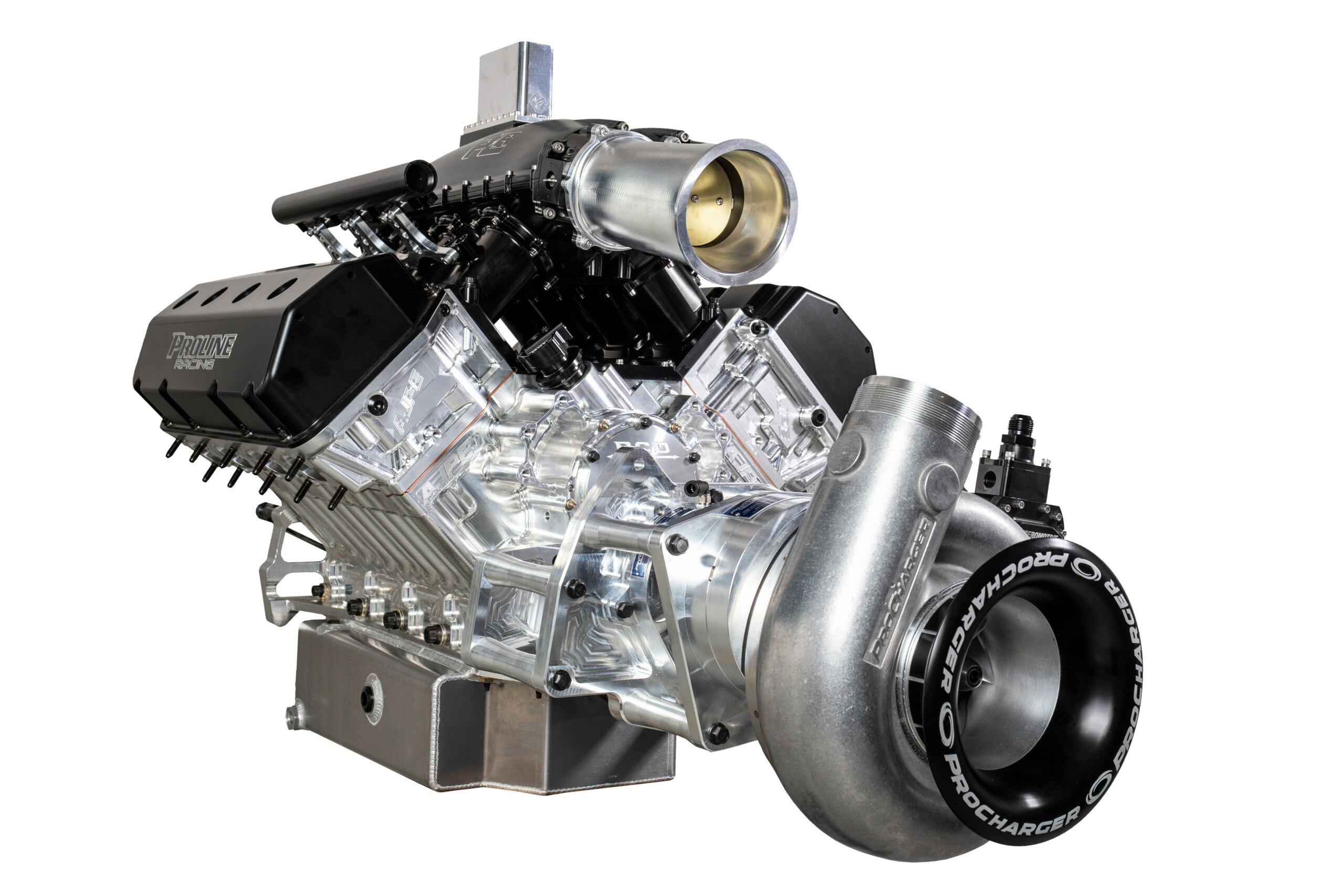

As Frank enjoys an existing relationship with Eric Dillard and Doug Patton from Pro Line Racing (PLR) in Ball Ground, Georgia, he gave them a buzz and had the PLR gurus spec out a combo that’ll run well into the threes on the Aussie eighth-mile. What turned up is one of PLR’s 3500hp raised-tunnel Hemis, based around an Alan Johnson TFX billet block.

The 10.725in-deck-height block rocks 4.467in bores with a total acreage of 564 cubes, while the Sonny Bryant CCW billet short-spline crank features larger throw to add strength, along with an eight-counterweight design that won’t flex as much as conventional cranks. PLR’s Doug Patton says some of the Hemi’s infamous appetite for parts comes from the sheer mass in the bottom end that the motor has to spin to make its prodigious power.

“The Hemi has a heavier bobweight on the crank, which makes it have more attrition, especially in valvetrain components,” he says. “The enemy of all these engines is rpm, and the Hemi likes to be turned more than a 481X, for example. Heavy engine internals being turned hard – sometimes 10,000rpm – with the pressure from boosted applications means parts wear out faster.”

The Bill Miller Engineering forged aluminium pistons are heavily reinforced around the base of the pin boss to improve strength between the slug and the Trend 1.04in pin. They’re attached to GRP aluminium rods, as per all PLR engines, and kept in place with a 7/16in ARP fastener.

One of the hot-sauce parts of this particular engine is the cam tunnel, or more specifically, where it is located in the block. The AJPE TRX billet block rocks a 0.600in raised cam tunnel filled by a custom-ground Comp Cams solid-roller that uses a core of high-quality tool steel.

Pro Line claims the new tunnel design improves valve control and adds stability to the valvetrain through the use of a larger 70mm cam core, shorter pushrods and revised rocker gear. PLR also fits larger head studs on the upper row of fasteners to improve clamping force, while deleting the inner row of head studs to allow removal of a cylinder head without lifting the intake manifold, potentially saving bulk time between racing rounds.

Acting on the Comp solid-roller are Jesel keyway lifters featuring a 0.937in body and running in a bronzed-bush lifter bore, while the pushrods are trick two-piece Smith Brothers 9/16in straight-wall units. SCE copper head gaskets are used on all PLR engines, while Clevite Vandervell-style bearings were chosen because they’re a softer-style of bearing that can better cope with the pounding that forced induction delivers. Out front is an RCD billet gear drive, which PLR uses on all its engines.

On top of the big-inch billet block is a pair of AJPE’s Stage IV Hemi heads. These are serious pieces of billet hotness, packing 2.490in (intake) and 2.020in (exhaust) Ferrea titanium valves, with gargantuan 104cc chambers and beefy 9/16in H11 head studs. Pro Line says the titanium valves will last thanks to the cooling properties of the methanol fuel these engines are designed to run on.

While Dandy Engines is renowned around our fair brown land as being responsible for some of the spiciest turbo combos to wear a pair of radials, this new powerplant relies on a giant 140mm ProCharger F-3 centrifugal supercharger. And Frank has a very good reason for opting for the front-mounted pump.

“The theory that makes ProChargers so exciting is downforce at the starting line,” he says. “At the line and on the two-step, a ProCharger should have 400lb of downforce coming out of the zoomies, which is a lot of power pressing down on the tyres compared to a turbo car.

“On 50psi boost, they’ll make between 3200hp and 3500hp. We’re turning it to 8600rpm at the moment, but it will go 9600rpm, and we will turn it ’til we can’t get any more out of it. We’ll push the impeller speed as fast as it can go.”

IN DETAIL:

- The intake manifold is, yep, billet. The Magnatron unit features twin 105mm front-facing throttles, though it can be ordered as a rear-entry piece. PLR has determined that plenum volume is key to making the big-inch intakes work with forced induction

- The fat Hemi heads are topped by roller-tip Reid billet shaft-mount rockers, which oil through a bronzed bushing. Comp Cams supply the tool-steel retainer used on the valve springs, instead of the usual titanium pieces. This is due to the high-quality metal’s lighter weight and strength

- The PLR Hemi costs approximately US$10K more than a 481X combo, and takes more than twice the amount of time to maintain. Some of the motor’s thirst for upkeep comes from it liking more rpm than the 481X, which tends to make more low-end power

- You may wonder why such an extreme engine isn’t running a dry sump system. PLR says the wet sump configuration they’ve developed with Moroso sheds precious kilos out of the race car’s total weight, but maintains excellent pressure characteristics. Oil is circulated by a System 1 billet oil pump mounted outside the pan

- Methanol is supplied by an Aeromotive Terminator billet fuel pump that flows an insane 26 gallons per minute, or 5904 litres per hour! There are 16 Billet Atomizer fuel injectors plugged into the intake manifold, which can be individually trimmed by the FuelTech FT600 ECU

OPEN SEASON

THE lads had their first hit-out at Sydney Dragway on 25 February for the Kenda round, and they came away smiling.

“We’re pretty happy, as our goal was to go 3.99, and we did 4.02 before the track closed early due to an oil-down,” Frank says. “We bombed the tyres once in 10 runs at our first meet, and we haven’t played with the shocks in the car yet. Our best 60ft was a 1.05sec, but I think it has a 0.9 in it. The number in my head is 3.78, and if I can get the 60ft where I want it, we should run a 3.93 without adding any power. And I still have the lock-up in the converter to turn on.

“Ideally, a car has two-to-five per cent converter slip going through the traps. We had 16 per cent slip on our 4.02 run, so we have that much more power to find. Also, the car weighs around 2900lb, but we want to be at 2600lb.”

“It’s insanely fast,” says Dan. “Because of the way it sounds, it’s a bit intimidating at first. The day we raced it was the first time I’d sat in it. I two-stepped it in the pits, cooled it down and then went and made a pass. When you’re sitting in there hearing that engine and you’re ready to go down the track, there’s nothing like it.”

BIRD IS THE WORD

DANIEL purchased the 2004 Pontiac Firebird housing the Hemi from Sydney radial racer Matt ‘Grubby’ Grubisa. Matt had bought the car from US racer Chris Daniels after being put onto the Racecraft Inc.-built F-body by PLR’s Eric Dillard.

Running a twin-turbo PLR 481X, its US PB had been 3.82@209mph, and it even got to the finals of Lights Out 2007 against Stevie Fast.

“I’d worked with the car in 2016,” Frank explains. “Steve Petty was working on the car with Chris Daniels, and little did we know five years down the track we’d own it!”

While a car’s styling isn’t a vital factor in a race car’s performance, Dan wasn’t a fan of the F-body’s late-model looks when he first picked it up, as he prefers his tin a bit older.

“I like 60s and 70s cars, so my ideal car would be an early Camaro or an HK Monaro in this style; that’d be the ultimate,” Dan says. “So I got the Firebird home and Dad and I ummed and ahhed about leaving it orange, but I rang him on a Friday and told him we’re painting it. Saturday arvo it was buzzed down and at the paint shop, and it was back a week later, finished.

When you see it in real life, it looks pretty trick; it’s grown on me!”

The decision to run with the big Hemi meant the car had to be cut from the front main bars forward, a new front end implanted, and the steering rack moved.

“So then we had to fix it all up and repaint under there,” Dan continues. “We modified all the rear end with different suspension, too. There’s new upper and lower arms, we made the links on the anti-roll bar longer, and gave it more tailshaft clearance, because there’s a lot more separation in the suspension on radials, so you need more clearance everywhere.”

While there is plenty of trick componentry underneath, it was originally built as a Limited Drag Radial (LDR) car and therefore is based around Outlaw 10.5.

“It has the same diff housing from Grubby, but we fitted a Tom’s billet centre and have 3.7 and 3.9 gears for it, plus a Mark Micke lock-up TH400, and a carbon-fibre tailshaft on its way,” Dan says. “Craig from OC Billet made the billet front engine plate as well as billet top and bottom tanks for the fuel tank. Matt from Snelly’s Fabrication then made the hole for the ProCharger to go through.”

Dan and Frank plan to share driving duties, and Dan is hopeful that Wally will take the wheel at some point, too.

“It’s my dad’s car too, and he and the boys were up here thrashing on it. Maybe we can twist his arm to put his big boy pants on one day and have a steer!”

WALLY & DANIEL SZABOLICS & FRANK MARCHESE

PRO LINE RACING HEMI

ENGINE

Block: 564ci AJPE TFX billet

Induction: Magnatron billet, twin 105mm throttlebodies

ECU: FuelTech FT600

Blower: ProCharger F-3 140mm

Heads: AJPE billet Stage IV Hemi

Camshaft: Comp Cams PLR tool-steel 70mm-core solid-roller

Conrods: GRP aluminium

Pistons: Bill Miller Engineering forged aluminium

Crank: Bryant CCW short-spline billet

Lifters: Jesel keyway

Rockers: Reid billet steel shaft-mount

Pushrods: Smith Brothers two-piece

Oil system: Moroso/PLR deep wet sump, System 1 billet pump

Fuel system: Aeromotive pump, Billet Atomizer injectors

Exhaust: Custom zoomies

Ignition: FuelTech FTSpark-8

THANKS

Steve Petty; Pro Line Racing; ProCharger; FuelTech; Dandy Engines; Marcus at Speed Pro & Speedflow; Billet Atomizer; Joe Gauci at Profab; Shane Marshall at Marshall Speed Shop; Shaine Benson; massive thanks to my crew of guys from home – Matt Snell, Simon Borella and Dean Soderblom; special thanks to my dad Wally

Comments