Damian Baker and Mick Green of BG Engines have screwed together some of the nation’s toughest engine combos for Powercruise entrants, pro burnout competitors and drag racers (including Street Machine Drag Challenge’s Radial Aspirated king, Alon Vella). They’ve even churned out a long list of highly strung marine racing mills. But after years of sitting on the sidelines, Damian and Mick decided to get involved in the action themselves.

First published in the September 2022 issue of Street Machine

Jotting down a quick list of the spare parts they had hidden under benches and stored in the rafters of their shop in Sydney’s semi-rural north-west, the boys figured they had enough good bits to slap together a pretty tidy little engine to thrash at Powercruise in this VE Commodore, which they co-own along with BG customer Adam Hodge.

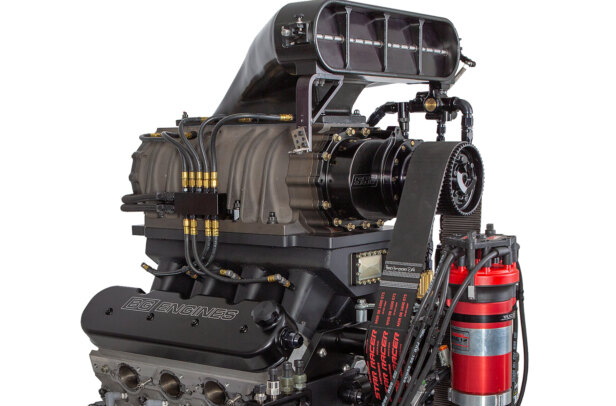

Much of the mill you see here was originally meant for the famed BG Engines HQ drag ute, which campaigned in the mid-2000s and was at one stage the quickest carburetted LS in the country. “We’d pulled the engine out of that, and I was actually using the block that’s in the VE as a step up to one of the machines in the workshop,” says Damian, alluding to the super-rare and wildly underappreciated World Products Warhawk LS7X block that now occupies the Commodore’s engine bay.

The blown, injected LS combo is stacked full of so many good bits, we’ve featured it in Mill of the Month as well. There you can read about the technical trickery and machining magic that helps this healthy small-block crank out over 1300hp at 8900rpm.

“Even with the LS7 heads that aren’t ideal for this combo, it kept making power all the way to 9000rpm, so we kept turning it!” Damian laughs. “However, in the interest of reliability, I’ve got the shift light set at 8000rpm for Powercruise, which means you’re probably shifting at around 8400rpm.”

Keeping the car reliable was priority number one – after all, with three owners all wanting seat time and a list of shop sponsors and supporters all wanting a lap or two, the only wrenching the boys wanted to do on the car at events was changing wheels and topping up fuel.

That reliability comes from a special combination of parts, assembled in a way that makes the car easy to work on and keeps the driveline safe. The dry sump oil system might seem like an unusual choice, but for Damian the move away from a wet sump was a no-brainer. “You can’t use a wet sump with the Jesel belt drive anyway, but for an engine like this, longevity is all about oil management and oil volume,” he explains. The VE boasts both, with a Peterson R4 pump, modified billet oil pan and around 15 litres of the slippery stuff on board.

Heat is the other big killer of blown combos, especially with that SSI 6/71 high-helix blower huffing wads of compressed violence into the LS. Keeping the bonnet off is a great way to lower engine bay temps, but the VE is ably assisted by a relatively simple radiator and electric water pump configuration. The majority of the heat is dissipated by the cooler-burning methanol fuel, with injectors positioned in the blower hat, the runners of the Pro Billet manifold and the rear of the blower.

Fuel is gravity-fed from the huge boot-mounted fuel cell to the belt-driven pump in the engine bay, which is tied into an intricate but effective engine protection failsafe.

“Everything is belt-driven, so we moved to a 24V charging system in order to spin the starter motor – and in turn the fuel and oil pumps – quicker at start-up,” Damian explains. “However, we’ve integrated everything on the front of the engine to run off the one belt. That way, if we lose a belt and lose fuel and oil pressure, the engine just shuts off instead of lunching itself.

We don’t have any other datalogging or electronic safety measures – the Racepak has a few warning lights set up, but in the heat of the moment when you’re grabbing gears sideways, you’re not always looking at them!”

But what made the boys wrap this exotic powerhouse in a garden-variety VE Commodore shell? “We work on a lot of the small-platform burnout cars like TUFF20 or even SKIDMA, where the engine bays are so small it can take you two hours to change a blower belt! We knew things like headers, for example, would fit nicely in a VE engine bay, and we can have the whole engine out in 40 minutes, which makes servicing a breeze,” Damian explains.

And as luck would have it, Adam Hodge had a VE shell to donate to the project.

“When we started this project four years ago, a VE made sense because parts like bumpers and quarter panels were everywhere and they were cheap,” Damian says. “But then Holden shut, COVID hit, and all of a sudden we actually had an expensive car on our hands! Plus, Michael Ellard from Image Conversions poked his head in and told us we couldn’t have an engine like that going into a shitty car!”

Michael (SM, May ’16) grabbed the shell, which had already been tubbed and extensively braced (including the visible bracing in the engine bay, full chassis connectors and the rear clip), and, with Adam Hodge whispering in his ear, set about transforming it into a stark, white, retro HDT homage.

After debuting in early 2022, the VE has just completed its second Powercruise event, and Damian admits they’re looking for as much track time as they can get in the car. “It’s not ’caged, so we’ve no intention of racing it,” he says. “We just want a tier-one pro burnout car that you can also see cruising at any Powercruise event – not just at burnout comps.”

DAMIAN BAKER, MICK GREEN & ADAM HODGE

HOLDEN VE COMMODORE

| Paint: | Protec white tinter |

|---|---|

| ENGINE | |

| Brand: | World Products Warhawk LS7X 389ci |

| Induction: | Pro Billet sheet-metal manifold |

| Blower: | SSI high-helix 6/71 |

| Heads: | Ported World Products LS7 |

| Camshaft: | Crow Cams custom solid-roller |

| Conrods: | Callies Ultra |

| Pistons: | Diamond pistons, 9.8:1 compression |

| Crank: | Bryant |

| Oil pump: | Peterson R4 dry sump |

| Fuel system: | Mechanical injection, Enderle spur-gear 9gpm pump |

| Radiator: | Custom triple-pass |

| Exhaust: | Hurricane Headers |

| Ignition: | MSD Pro Mag 12 |

| TRANSMISSION | |

| Gearbox: | TH400, JW Ultra-Bell bellhousing |

| Converter: | SDE 4000rpm |

| Diff: | SCW sheet-metal 9in housing, 3.25:1 gears |

| SUSPENSION & BRAKES | |

| Front: | XYZ coil-overs |

| Rear: | Strange coil-overs, four-link |

| Brakes: | HSV 365mm rotors and four-piston calipers (f & r) |

| Master cylinder: | Wilwood |

| WHEELS & TYRES | |

| Rims: | Simmons FR; 22×8 (f), 22×12 (r) |

| Rubber: | 245/30R22 (f), Atturo AZ850 315/30R22 (r) |

THANKS

Image Conversions; SDE Torque Converters; SKIDMA Fabrication; Al’s Race Glides; Billet Buttons; Crow Cams; BAM Lifters; KA Electrical; SRC Race Cars; Motorsport Connections; Speedflow; Shev at Hurricane Headers; Hawkesbury Truck Tyres; Keith Amor for wiring; Tom Baker for helping on the car every night.

Comments