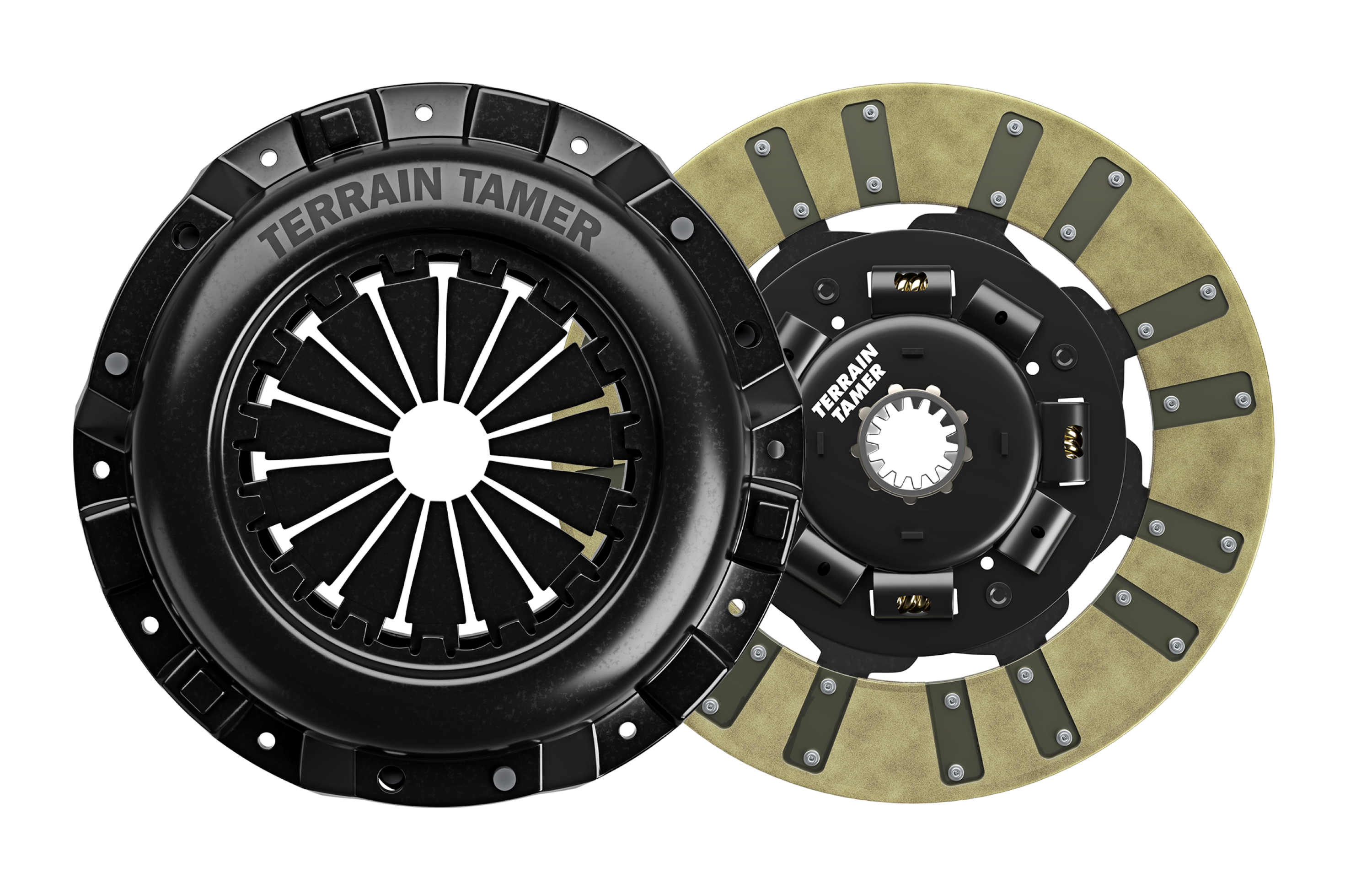

Terrain Tamer has released its newest innovation in the form of Fortified Plus Clutch kits.

Arriving several years after the release of the brand’s original Fortified Clutch range, this new standard in clutch technology extends the company’s existing catalogue of standard replacement and heavy-duty clutch kits.

Superseding the previous Fortified range, the Fortified PLUS Clutches are OE-manufactured and exclusive to Terrain Tamer and follow the company’s legacy of producing stronger, improved parts for 4WD applications.

The Fortified Plus Clutch range was purposely designed with the extreme weight and engine capacity of armoured vehicles in mind. It offers up to an impressive 80 per cent increase in torque capacity, making it perfect for vehicles with GVM upgrades where the clutch is often the weakest point, or for those carrying extremely heavy loads or with increased power from upgrades such as chips, aftermarket exhausts and turbos.

After many years of developing and testing a variety of designs and friction materials, the Fortified Plus Clutch range employs exclusive Terrain Tamer tooling. All components have been made in Japan, including an innovative clutch disc design that utilises Clutchtex Kevlar material on both the engine and transmission facings to combat shuddering, a technology not previously used in the 4WD industry.

This Kevlar compound offers a significant increase in strength and a longevity of up to 2-3 times the OE counterpart, paired with smoother engagement and a softness that ensures the flywheel and pressure plate remain unmarked. This design also features an increase in damper spring capacity, friction material coefficient and the burst strength of the facing. Where applicable, it also features a three-stage damper design.

“We believe our new Fortified Plus Clutch is the first Kevlar 4WD Clutch on the market,” said Skye Kottachchi, marketing manager at Terrain Tamer. “This is exciting now only because it offers an unmatchable strength, up to three times as strong as the original, but it addresses the issue of shuddering that many users of heavy duty clutches report.”

The Fortified Plus Clutch cover assembly is anodised for maximum corrosion resistance and features a spheroidal graphite anti-burst pressure plate casting, to both assist in the extended life of the clutch and allow it to run cooler in extreme situations. It offers higher clamp loads and additional drive straps for strength, where required.