A joint venture between automotive manufacturer Volvo and fellow Swedish company SSAB has been established to develop fossil-free steel, bringing net carbon emissions of a car’s life cycle down.

The collaboration is a first for any automotive company, reflecting Volvo’s recent commitment to go green by investing in battery technology and the ultimate aim for its entire range of cars to be EVs by 2030.

The partnership makes Volvo Cars the first carmaker to work with SSAB and its ‘Hybrit’ initiative – the steel industry’s most ambitious and advanced project in fossil-free steel development.

Hybrit was started by SSAB, together with iron ore producer LKAB and energy firm Vattenfall. It aims to replace coking coal, traditionally needed for iron ore-based steelmaking, with fossil-free electricity and hydrogen. The result is expected to be the world’s first fossil-free steelmaking technology, with virtually no carbon footprint.

The ultimate aim from SSAB is to supply the fossil-free steel on a commercial scale by 2026, with Volvo utilising the product in concept cars for testing before implementing the materials in its production cars.

Volvo’s Chief Executive, Håkan Samuelsson, says the development of fossil-free steel is important for Volvo in its aim to reduce carbon emissions.

“As we continuously reduce our total carbon footprint, we know steel is a major area for further progress,” said Samuelsson.

“The collaboration with SSAB on fossil-free steel development could give significant emission reductions in our supply chain.”

SSAB CEO Martin Lindqvist believes the new process has next to no carbon footprint and will help Volvo in achieving its goal with a larger ambition of being used across the industry.

“We are building an entirely fossil-free value chain all the way to the end customer,” said Lindqvist.

“Our breakthrough technology has virtually no carbon footprint and will help strengthen our customer’s competitiveness.

“Together with Volvo Cars, we aim to develop fossil-free steel products for the cars of the future.”

Currently, steel and iron production accounts for 35 per cent of total CO2 emissions in the production process for Volvo’s internal combustion engine powered cars and 20 per cent in its electric vehicles, with the global steel industry accountable for seven per cent of overall carbon emissions.

We recommend

-

News

NewsVolvo enters joint venture to develop and produce batteries

New joint venture aimed at bringing everything in-house for Swedish battery tech

-

News

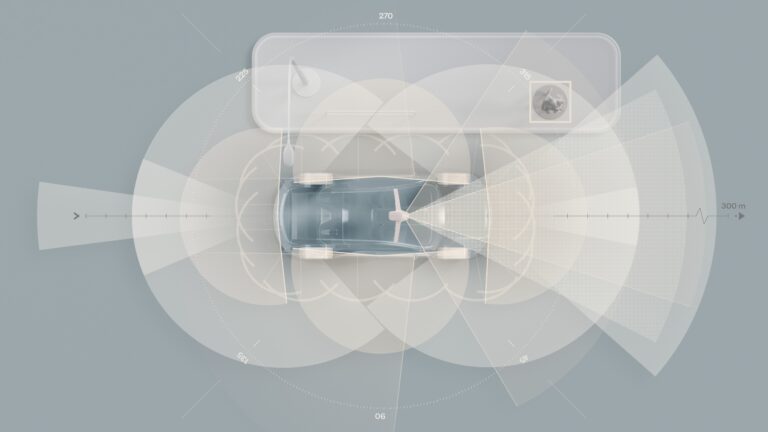

NewsVolvo's next-gen EV will use LiDAR, XC90 going fully-electric

The next Volvo XC90 is going electric – with autonomous capabilities too

-

Opinion

OpinionOpinion: Older manufacturers will overtake Tesla in the EV space

Volvo believes that the favoured technique of sharing an EV "skateboard platform" is the wrong way to develop good EVs