When Nissan announced the GT-R’s engine contained ‘Plasma infused bores’ in 2008, it sounded like reality had caught up with science fiction.

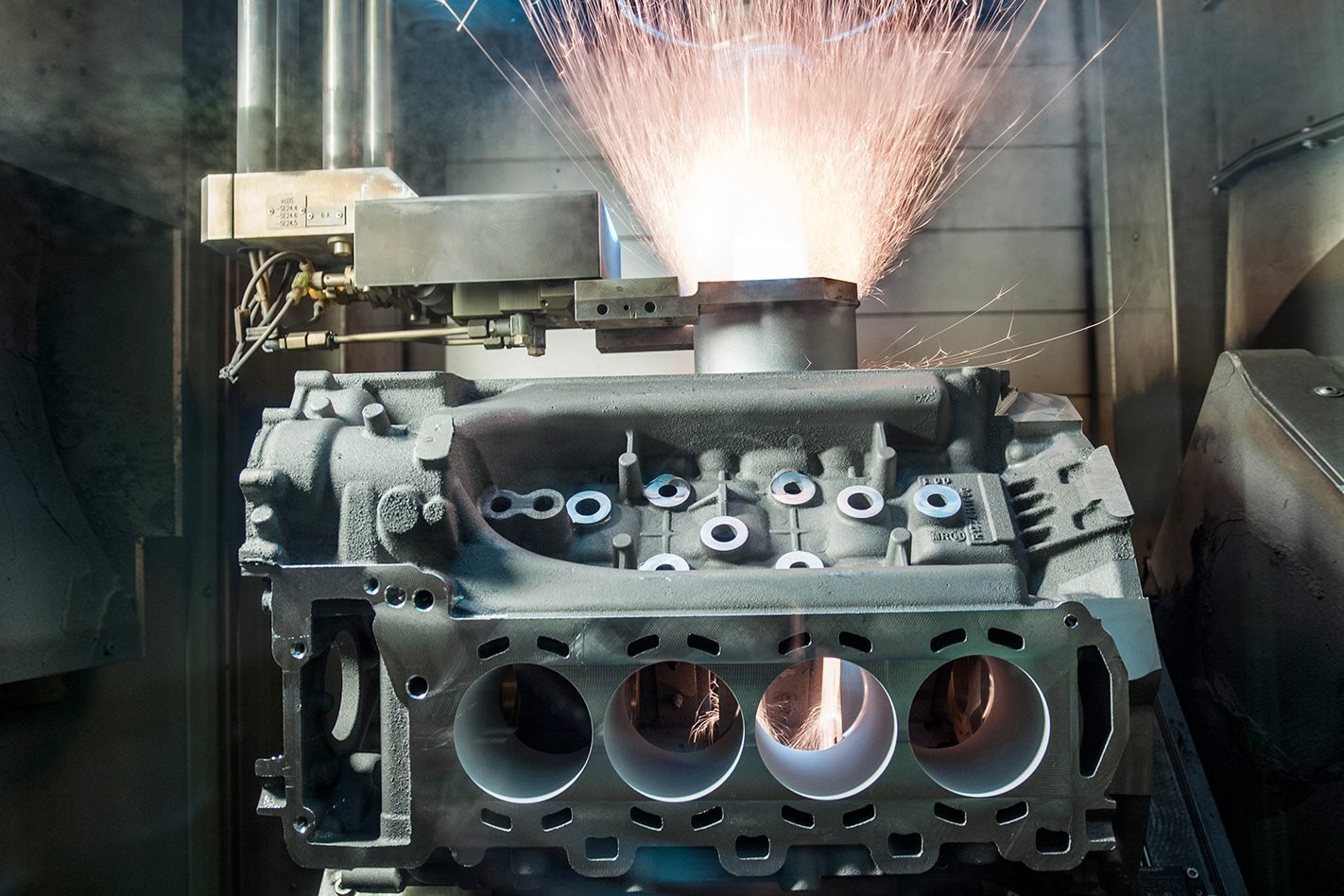

What this referred to, though, was a process of coating the cylinder bores of an engine block with a special material melted within a gas made from an electric spark. High-tech, yes, but why was it a performance tool for the GT-R?

Well, when weight-saving measures were in their infancy cylinder blocks were made from iron, a material praised for its sturdiness. But as engineers became increasingly desperate to find areas where weight could be zapped, the iron block was shown the door.

Then entered cast aluminium blocks. Aluminium achieved the weight savings needed, but also presented a problem – aluminium pistons couldn’t run in an aluminium bore as the friction would be too high. The solution figured was to fit thin iron liners pushed into the aluminium block.

Originally developed for motorcycle engines, Porsche trialled it in its 917 racers before applying it to road car power plants. It involved spraying a Nickel-Silicon Carbide plating on to engine cylinder bores.

This eliminated the liner, allowing the block to remain strong (it didn’t need to have as much parent material cut out of it), and allowed Porsche to bore out the cylinders, increasing displacement.

Nissan shone the lime-light back on similar technology when it announced the ‘Plasma Infused Bore’ (or ‘Plasma transferred wire arc thermal spraying’) process used in its R35 GT-R, which sprays the VR38’s aluminium bores with a thin (0.15mm, compared to traditional cast liners of 2.6mm) coating of iron that is super tough. It also shaved 3kg from the 3.8-litre twin-turbo V6’s weight.

Furthermore, not only can ‘wire-arc’ spraying save weight, it permits the use of a ‘closed deck’ design. This means there are no open channels in the top of the block to accommodate iron liners, which increases strength dramatically.

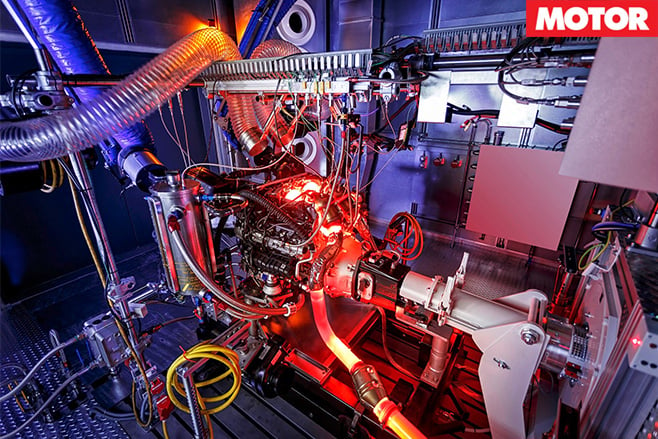

With the M156 Mercedes debuted ‘twin-wire arc’ spray coating, a process which it considers superior to other wire-arc systems and neatly dubbed ‘Nanoslide’ technology. It’s also made its way into the firm’s F1 engines.

But is this just the stuff of supercars? While ‘wire-arc’ coating is complicated and expensive, it’s actually more cost-effective overall. And if we also consider that it improves cylinder sealing and friction loss – a win for efficiency – we should hope to see it more widespread in future.

BORED YET? In Mercedes-Benz’s case, ‘Twin wire-arc’ technology melts a mixture of iron/carbon wires in an electric arc that creates a mist. It then literally sprays this onto the cylinder walls.

CALM & CONTROLLED It might sound relatively simple but the spraying requires tight control of current, voltage, wire feed and gas flow to achieve an ‘ultra-fine nano-crystalline coating’.

NICE & POLISHED Once the coating is applied, a whole lot of time is taken honing the surface to achieve what looks like a mirror finish to the naked eye.

OILED UP Yet, while it may look like a mirror finish, there are tiny microscopic pores exposed by the honing. These pores trap lubricating oil and keep the piston cushioned in the bore.

BIG LOSER Mercedes claims that, compared to grey cast-iron cylinder liners, its Nanoslide technology reduces ‘mechanical friction losses’ by up to 50 per cent.

ARCING UP