Swedish steel company SSAB will be supplying German manufacturer Mercedes-Benz with fossil-free metal in the future as the automotive company aims to make carbon-neutral production a reality.

While Mercedes-Benz has already committed to going electric only by 2030, the brand is targeting a reduction in its carbon footprint across the supply chain, which is where SSAB comes into the equation – having already set up a pilot plant to produce fossil-free steel in Sweden.

SSAB’s ultimate aim is to supply the automotive market with such steel from 2026, a goal it is on track to achieve after Volvo recently announced it was entering a joint venture with the steel maker to accelerate the development process.

Mercedes-Benz has set a time limit on achieving carbon-neutrality, wanting its entire passenger vehicle fleet to be emission-free in every stage of the manufacturing process by 2039 at the latest – ahead of the 2050 target implemented by a majority of other companies and the European Union.

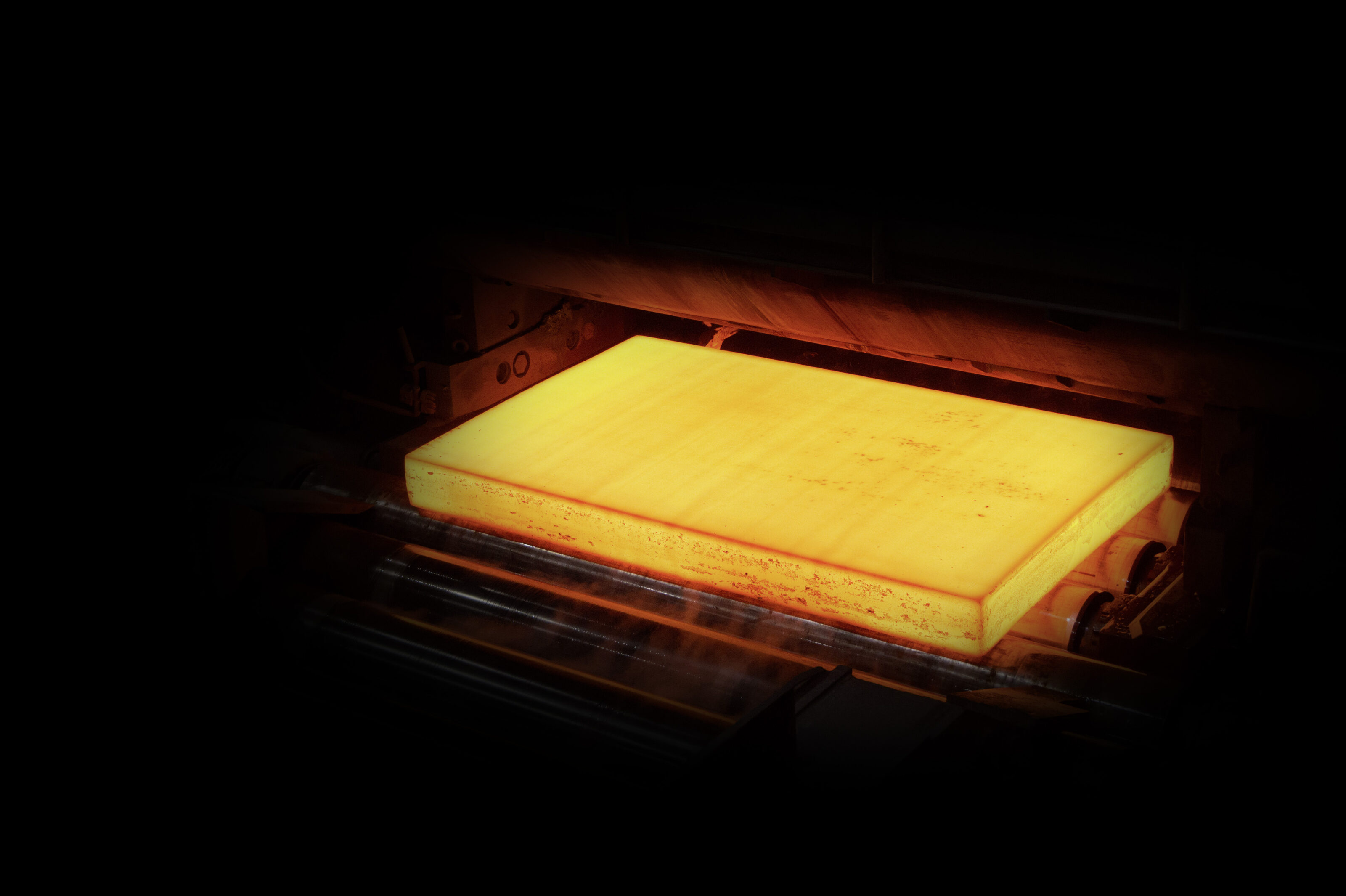

As opposed to regular steel production – which relies on coking coal – the carbon-neutral process utilises hydrogen and fossil-free electricity, bringing the environmental impact of production down significantly.

Although Mercedes-Benz hasn’t released any insight as to how much the process would account for CO2 emissions in production, Volvo estimates up to 35 per cent of its production emissions are from the steel manufacturing process.

We recommend

-

News

NewsMercedes-Benz to become fully-electric by 2030 – but with one condition

The world's first automotive manufacturer will be making sizeable investments to remain on-track for its target

-

News

NewsVolvo invests in joint venture to develop fossil-free steel

Swedish joint venture aims to bring fossil-free steel to the car industry

-

News

NewsEU officially proposes ban of ICE vehicles from 2035

ICEs on notice ahead of proposed ban in 14 years