Snapshot

- Subaru to shut all Japanese plants

- European and North American factories also halting production

- Industry warns supply squeeze to continue to 2023

Subaru has suspended all production at its Japanese factories, citing issues with the supply of semi-conductors.

While Subaru has provided few details about the four-day shut down, it’s understood the plant closures are related to the ongoing global semi-conductor shortage.

The news comes at the same time as Stellantis announced it had extended a stoppage at its Melfi manufacturing facility in Italy, responsible for building the Jeep Renegade, Jeep Compass, and Fiat 500X SUV. Stellantis has also temporarily closed its North American plants, which build the Ram 1500 pick-up.

Earlier this week, Renault announced it would also extend temporary shutdowns at three of its factories in Spain, which produce the Megane, Kadjar, and Captur models. It’s a similar story at Suzuki’s factories in Hungary.

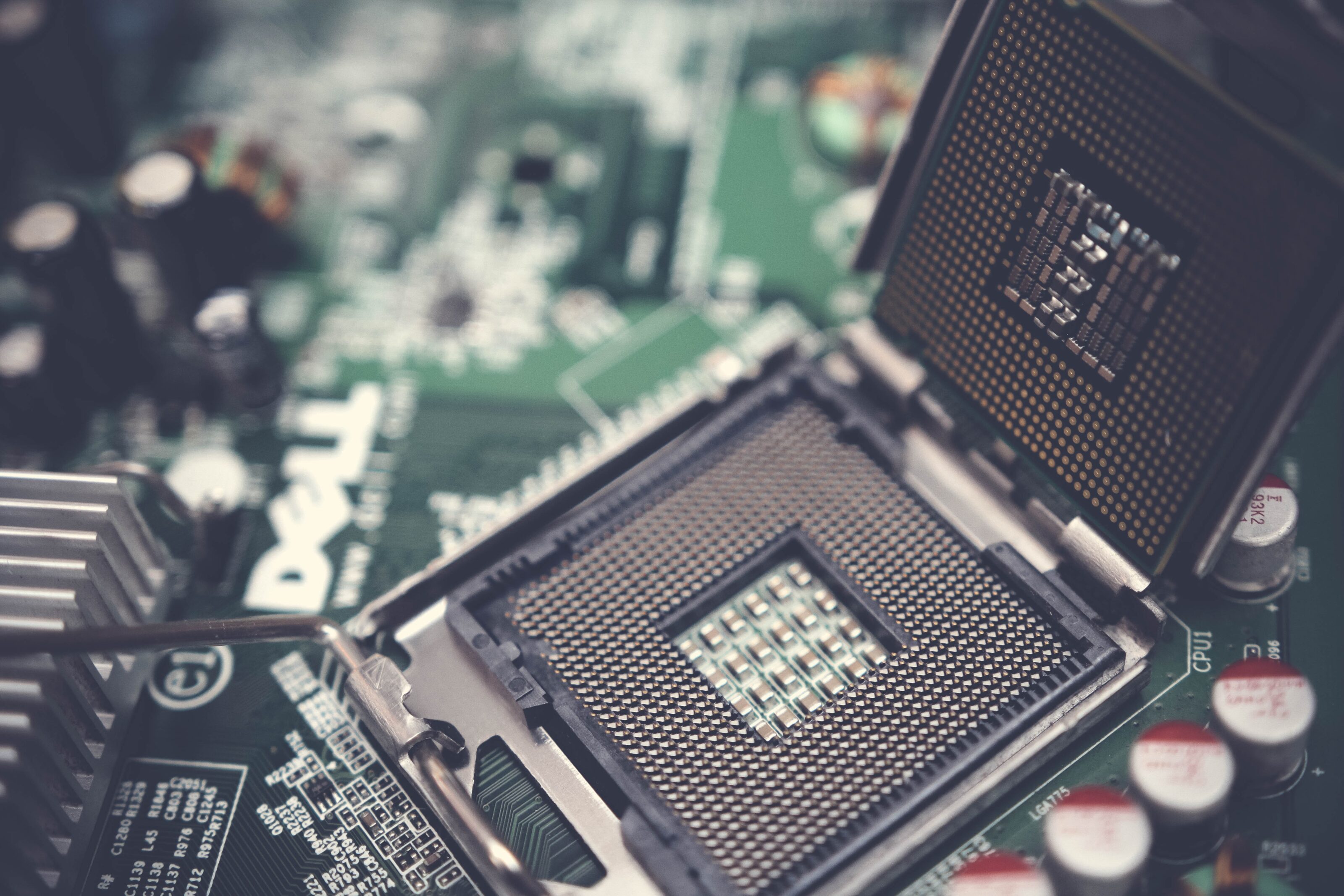

Semi-conductor chips are used extensively in the production of new cars, with up to 200 being fitted in petrol and diesel models, and electric vehicles needing as many as 3500.

While COVID-19 is largely accepted as the main catalyst for the supply squeeze, other factors including international trade tensions and a drought in Taiwan have also contributed.

Adding insult to injury, in March a semi-conductor company, which supplies Toyota, Nissan, and Honda, experienced a fire at its Japanese factory – causing stocks of all three carmakers to suffer.

Tesla boss Elon Musk has delayed production of its long-awaited Roadster model until 2023, tweeting: “2021 has been the year of super crazy supply chain shortages, so it wouldn’t matter if we had 17 new products, as none would ship.”

He added the Roadster should begin production in 2023, “assuming 2022 is not mega drama”.

Despite foreseeing such a scenario and stockpiling chipsets, the supply shortage eventually caught up to Japanese car giant Toyota, announcing it would reduce production by 40 per cent over the month of September.

The move impacted 14 of its Japanese factories, taking its monthly new-car output from 360,000 to just 140,000 – and delaying Australian deliveries of the new LandCruiser 300 Series.

All major car manufacturers have reported some kind of impact to production over the past year, but there appears to be no sign of respite.

The follow-on effects are impacting new-car buyers in Australia, with dealers struggling to secure enough stock for customers.

Industry insiders have told WhichCar the problem is so extensive, dealerships are now refusing to swap their vehicles with other dealerships within their branded networks, forcing people to shop outside of their local area – and sometimes even interstate.

The current factory shutdowns are expected to only exacerbate the problem in the coming months.

Japanese semi-conductor company Rohm – which lists among its customers Toyota, Ford, and Honda – is warning the pain will continue throughout 2022.

“All of our production facilities have been running at full capacity since September last year, but orders from customers are overwhelming,” CEO Isao Matsumoto told Bloomberg in late August.

“I do not think we can fulfil all the backlog of orders next year.”

The comments join a chorus of warnings from the semi-conductor industry, car companies, and business analysts – who caution the supply disruptions won’t be resolved until at least 2023.

We recommend

-

News

NewsToyota announces production cuts, delays to Australian LC300 deliveries

Most popular brand in Australia will face future stock shortages

-

News

NewsSemiconductor shortage forces worldwide car production slow down

Electronic componentry shortages to blame for worldwide car factory slow downs

-

News

NewsVolkswagen Australia launches website to provide stock delay updates

Mounting VW delays due to semi-conductor shortage lead to local website launch