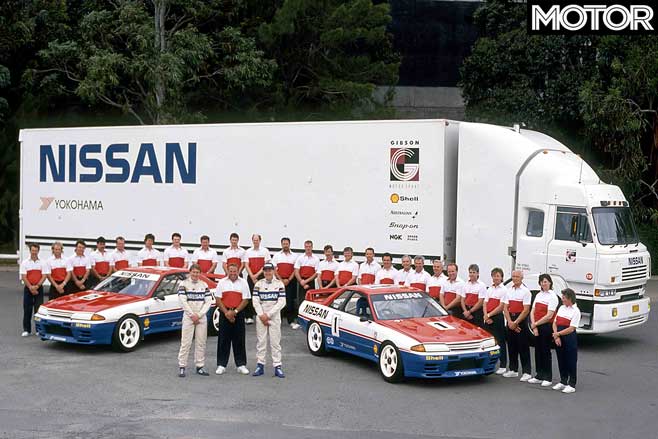

We gathered Mark Skaife, Fred Gibson and former Nissan Oz product planning, design and Special Vehicles boss Paul Beranger to tell us about the Australian R32 GT-R race car program and how it produced a car beyond the original developed by Nissan.

The full interview with Mark Skaife, Fred Gibson, and Paul Beranger can be found in the September 2019 issue of MOTOR Magazine, on sale now.

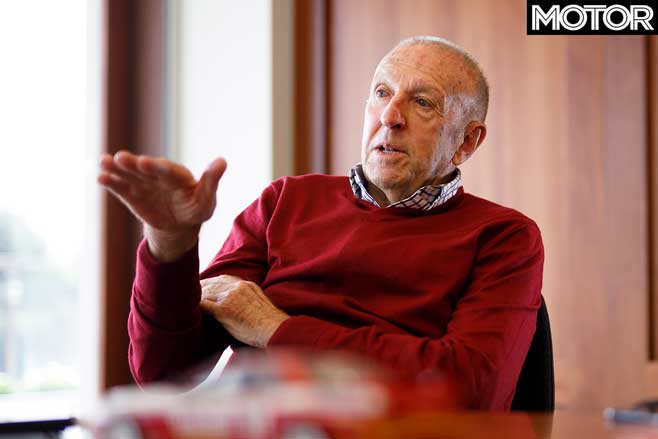

“You have to remember that our touring car category in Australia was very competitive, and the thing is, a Japanese-spec race car wouldn’t win here,” Gibson says.

“It wouldn’t be quick enough against the Ford Sierras and Holden Commodores. So we had to homologate the parts on it that we wanted on the car with the FIA through CAMS to make the race car a better car, and that took a lot of work.”

“Part of the problem was that in Japan they didn’t really have to develop the car because they controlled the formula. The more they developed, the more they had to spend, whereas we had to keep developing, and at every race the car changed. The Japanese were aware of that.”

The Aussie overhaul of the R32 racer was comprehensive, as Gibson explains: “Suspension, wheels, gearbox, clutch, engine… Like cylinder blocks, for example.

“We put an engine on the dyno and cracked the block because of the extra power we were trying to get out of it with a different engine management system. So they had to make special blocks for us. They were good at doing that, but it took time – and money. A lot of money.

“A part of going local was to save money because the Japanese parts were just silly money.

“A competition water pump from Japan was about $15,000 and all they did was change the impeller on it, which we could do here and use the normal water pump. A dog box gearbox was $60,000.

“Nismo were there to make money, whether we were Nissan or not. They still charged an arm and a leg. So we went away from using Nismo stuff.

“The wheels, the suspension, the gearbox were all local. They made the cylinder blocks, but the Electromotive engine management system was done for us in America. We did it all ourselves, which was still very expensive, but not as expensive as getting all the bits from Japan.

“Our budget was huge. We were very fortunate to have good sponsors as well as Nissan Australia.”