Snapshot

- Volkswagen signs with Perth-based Vulcan Energy Resources

- Electric vehicle production targeted at 2.2 million per year by 2030

- In-house production a step towards reducing overall emissions

Volkswagen is making good on its battery expansion plans, signing a lengthy contract with an Australian company.

Signing three new deals secure its supply of batteries into the future, it’s an important step in Volkswagen’s goal of producing batteries in-house and having the capacity to produce millions of electric cars every year.

Key to its new partnerships is a deal with Australian company Vulcan Energy Resources, based in Perth and operating in Germany. The new partnerships also see Volkswagen working with Belgian mining company Umicore, and US start-up 24M.

Volkswagen’s partnership with Vulcan Energy Resources is a long-term contract which secures a supply of CO2-neutral lithium. This ‘clean’ lithium helps address contention around the environmental impact sourcing rare earth metal causes.

While Vulcan’s headquarters are in Perth, the lithium will be sourced for Volkswagen from the Upper Rhine Valley which borders Germany, Switzerland and France. The deal will last at least five years before any extension is triggered, and given the importance on reduced emissions and sourcing clean materials for new cars, it could well go into the new decade.

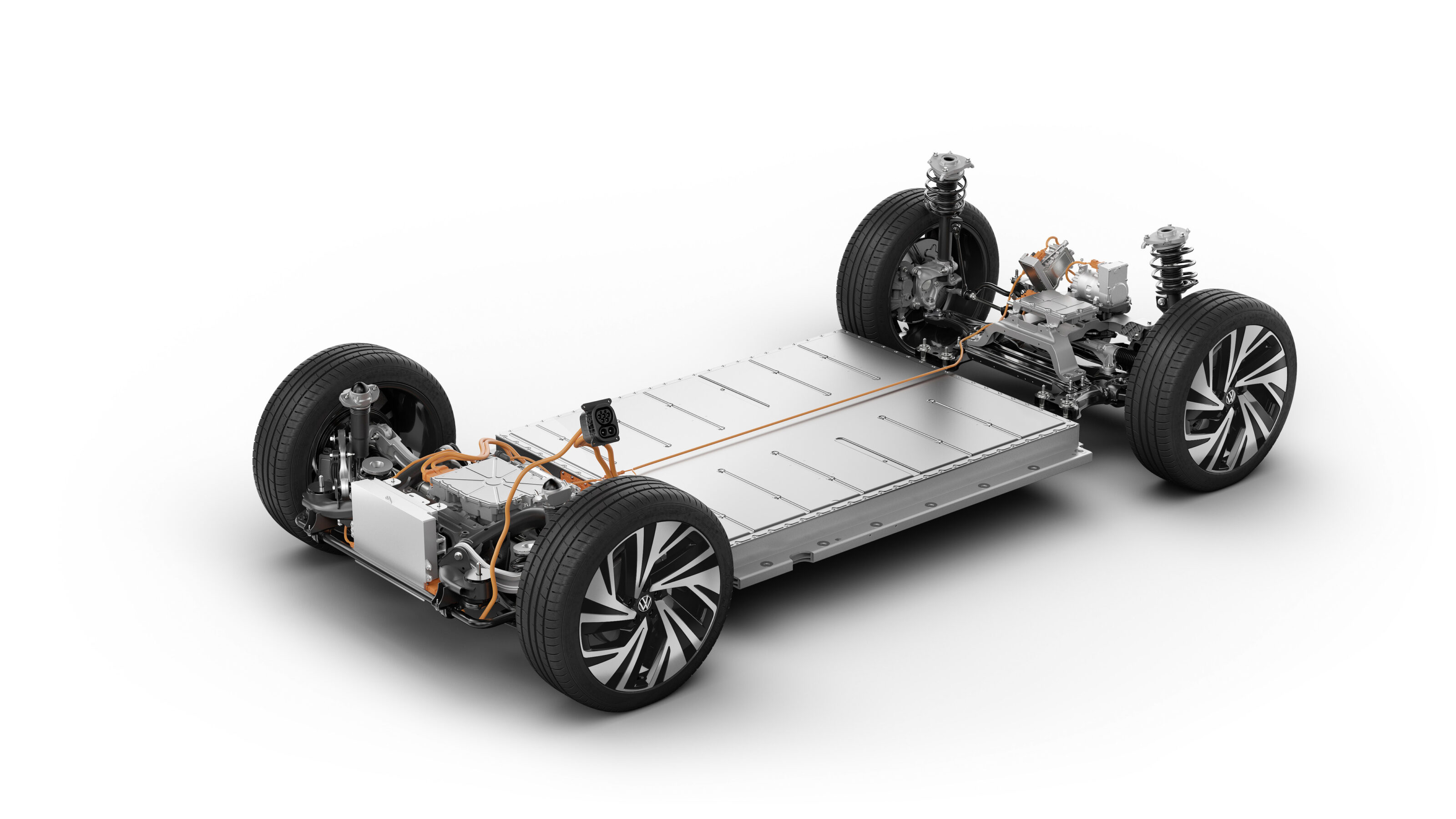

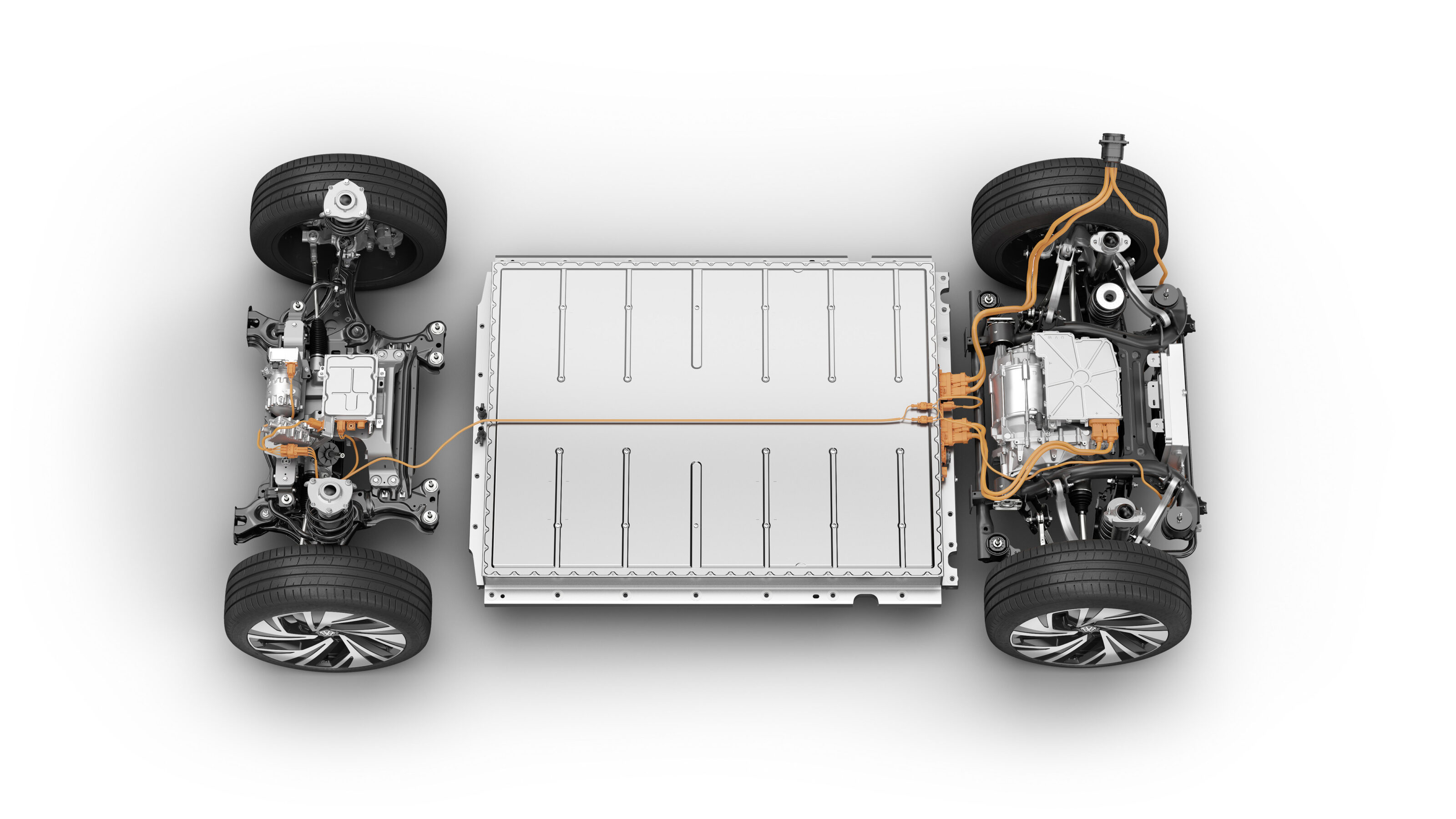

With the other two partnerships and a target of opening six new gigafactories to produce its own batteries this decade, Volkswagen believes by 2030 it will be able to achieve an annual production capacity of 2.2 million electric cars – but it will certainly need support from industry specialists.

Umicore, one of the new partners, is a specialist mining company which sustainably sources materials to produce battery cathodes, while lithium-ion production specialists 24M – based out of Massachusetts, USA – has breaking technology for a dry coating system during production which reduces the need for extra processing.

Most importantly, this new way of processing lithium-ion batteries reduces CO2 emissions and makes them easier to recycle, thus reducing the overall environmental impact from sourcing materials to constructing the car itself – which is how EVs without tailpipe emissions are beginning to be judged.

We recommend

-

News

NewsFederal Govt eyes EV growth, provides $2bn backing to Australian mining

A new credit facility has been created to help fund mining operations in Australia, with electric vehicle batteries manufacturers expected to benefit

-

News

NewsToyota will have solid-state batteries “in a couple of years”, says exec

Toyota is leading the charge on the holy grail of EV powertrains and promises 10 minute recharges and 1200km+ range isn't far away

-

News

NewsVolkswagen production at Wolfsburg plant at lowest point since 1958

The global semiconductor shortage has played a part in the 63-year low