Volvo is building a ‘mega-casting’ plant to speed up the construction process of its upcoming electric cars, as well as increasing efficiencies.

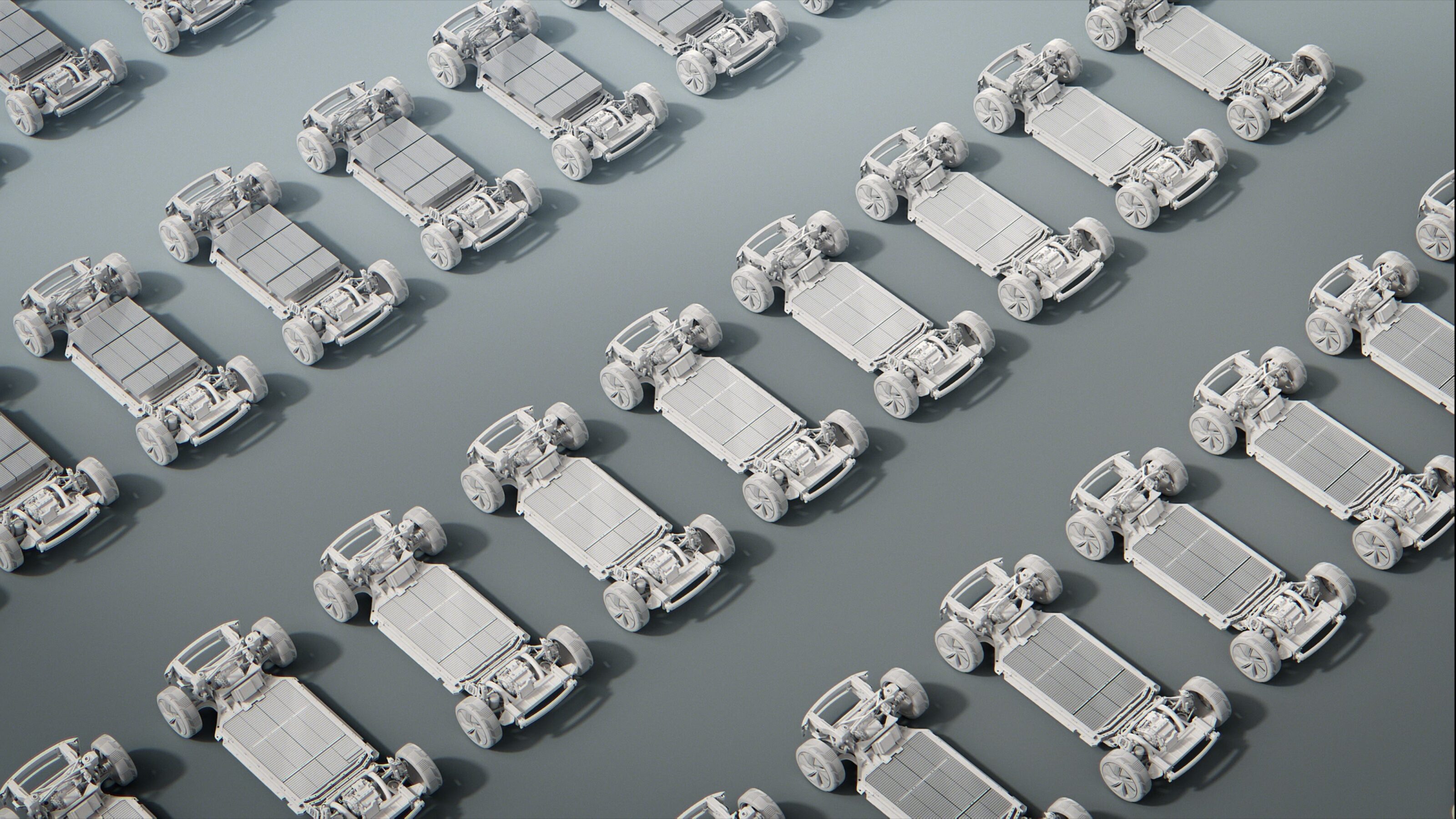

Like Tesla’s casting plant for the Model Y, Volvo will be doing much the same at its Torsland plant in Sweden. In Volvo’s revamped facility, vehicle moulds will be created with as many components built into the panel as possible to reduce the assembly of parts.

Volvo is investing $1.5 billion into revising the existing plant so it can quickly cast large panels and components. The first car to use the new technique will be produced in 2025, giving the Swedish car maker three years to finish the rebuild.

“With these investments we take an important step towards our all-electric future and prepare for even more advanced and better electric Volvos,” said Håkan Samuelsson, Volvo chief executive.

“Torslanda is our largest plant and will play a crucial role in our ongoing transformation as we move towards becoming a pure electric car maker by 2030.”

The first model could be the upcoming ‘Embla’ EV and the casting will provide a large floor pan cast with points for suspension and electric architecture ready to go, negating the need for a rear subframe. In total, Volvo says it will remove around 100 parts from each car and it also expects its mega-cast panels will improve the safety of its electric vehicles.

With fewer parts, cars should weigh less too, providing other benefits such as being more efficient and aiding performance. Other benefits from mega-casting include reduced complexity in the manufacturing process which saves costs in terms of materials used as well as logistics.

Along with the casting, a new battery assembly plant will integrate battery cells and modules in the floor structure of the car. The assembly shop will be rejuvenated too, ready for the next generation of fully electric cars that use a new ‘marriage point’ where the top body and the floor of the car meet for the first time.

“Today is a great day for the Torslanda plant as we are making it fit for the future with this investment package,” said Javier Varela, head of engineering and operations at Volvo Cars.

“Our future as a company is all-electric and that requires a variety of upgrades across the plant, to ensure that Torslanda can continue to build premium electric cars of the highest quality.”

We recommend

-

News

NewsVolvo's XC90 successor to be named Embla

The name of Volvo's first non-alphanumeric vehicle in over 50 years has been uncovered

-

News

NewsVolvo planning all-electric model between XC60 and XC90

It's understood the new vehicle will be the first fully-electric model to be built in the South Carolina plant

-

News

NewsVolvo to build its own gigafactory in Sweden

Volvo to produce its own batteries as part of a cleaner ‘end-to-end’ production solution