Tyres are the only object between your car, all who sail upon her and the road’s surface so they have a huge responsibility and a big part to play in making sure driving is safe, fuel efficient and – for some – fun.

Put simply, they are an ultra-durable matrix of many complex components encased in moulded rubber, the net result of which provides a grippy surface on the outside for holding onto a variety of surfaces, with a void on the inside that is filled with compressed air for good ride comfort.

You’ve probably heard the adage that the actual contact patch of a tyre on the road is about the size of the palm of your hand, which highlights their remarkable job of controlling the thousand-odd kilos of the average passenger car. So how do they do it?

Whether you treat yourself to top-quality European hoops or a budget set of boots, all tyres adopt the same basic construction.

On the outside, the visible rubber part of a tyre does not actually include much natural rubber at all and is comprised of about 70 per cent synthetic butadiene and polybutadiene rubber, which has similar sticky properties to natural rubber but offers far better durability.

Tread patterns vary enormously and are often the most obvious way a tyre manufacturer can apply a recognisable brand to its products, but it’s all a balancing act.

At one end of the spectrum there are deep knobbly treads that will offer the best traction in wet mud and loose surfaces but at the other end there are near-slick tyres that have almost no tread for optimum grip on a dry race track – and everything in between.

Unless you are an off-road weekend warrior or Daniel Ricciardo it is unlikely you have either of the extreme examples fitted to your car. Rather, regular road tyres are a little less specialised.

In some ways, the average all-rounder tyre has a harder challenge though, and has to offer an acceptable level of grip in all conditions, over tens of thousands of kilometres and accommodating of all driving styles.

While the role of the tread is to offer some mechanical grip on uneven asphalt and some slippery surfaces, its main job is to clear water in wet conditions and allow the rubber to stay in contact with the road.

Aquaplaning is when a tyre is travelling so fast enough over water that it effectively skis on top of the puddle rather than displacing the water and staying in contact with the road, and it feels similar to driving on ice – not good. Steering and braking control disappear, and an accident is often the result.

The complex tread pattern of high-quality tyres gives that water an emergency exit from the contact pathc, preventing the vehicle riding up onto the water’s surface and maintaining control.

Water is a very effective lubricant of rubber and even when there is only a small amount of water on the road it can still present a hazard. The rubber on your tyre is a carefully blended formula to offer the best grip when wet and works in partnership with the mechanical grip of the tread pattern.

Look even closer and you’ll often see smaller slits in the tread called sipes. These tiny heroes give water somewhere to go if it can’t be syphoned out of the tread pattern by the larger channels, boosting wet weather performance.

On a snow tyre, the sipes serve a different purpose and operate on the principle that the most tractive substance on snow is more snow. As the tyre rotates, the sipe opens up and grabs a tiny handful of snow which then sticks to the snow covering the road. As the tyre continues to roll, the sipe opens up again and throws the snow behind the vehicle. Cool.

You might have also noticed that the pattern of tread blocks is never symmetrical in the direction of rotation. Why? A perfectly spaced spread of blocks creates a noticeable whine when rolling, but with a variable block pattern the pitch patterns constantly change and are less intrusive than a single note.

But the bit you can’t see is arguably the hardest-working part.

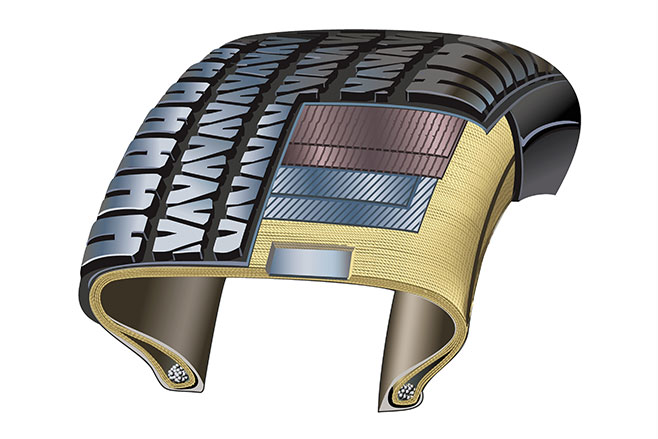

Wrapped up in the outer black layer is a complex structure of layers that maintain the tyre’s shape even when heavily loaded, carving corners at speed or under heavy acceleration and braking.

The ‘carcass’ forms the basic doughnut shape of the tyre with nylon – or sometimes Kevlar – plies, while a stiffer matrix of steel wire and nylon fibre belts strengthen and flatten the section under the tread pattern.

In some tyres, the stiff belts are extended into the sidewall of the tyre and can support the weight of the vehicle for a limited time even when punctured. These special safety tyres are often called ‘run-flats’ even though they don’t actually go flat when the pressurised air leaks out.

But, if you can make a tyre that runs safely without air in it, then what is the point of conventional pneumatic technology that hasn’t changed in basic principle for more than 100 years?

Despite the efforts of many manufacturers, no alternative to pressurised gas inside a tyre has provided the same ride comfort, lifespan or performance as the original idea.