Snapshot

- Factory worth AU$1.57bn opened in Dresden

- Over 700 employees will work alongside artificial intelligence

- 20-week manufacturing process means delays won’t be over for getting semi-conductor stock

Electronics company Bosch has opened a new €1 billion (AU$1.57billion) semi-conductor factory in Dresden, Germany, in the hopes of getting on top of the global computer chip shortage.

With 700 staff on deck, Bosch will initially start production at the factory in July with work commencing on semi-conductors for its power tool range, following which automotive production is expected to start in September.

The semi-conductor shortage has caused widespread issues across the auto industry of late, initially triggered by an unexpected rise in demand, but further complicated by blackouts at production facilities in Texas and a fire at a Japanese plant.

Bosch’s commitment to the factory is the biggest single investment in the company’s history, signalling an intention to not only help alleviate the current shortage, but a commitment to provide stock into the future as the automotive industry adopts EV technology.

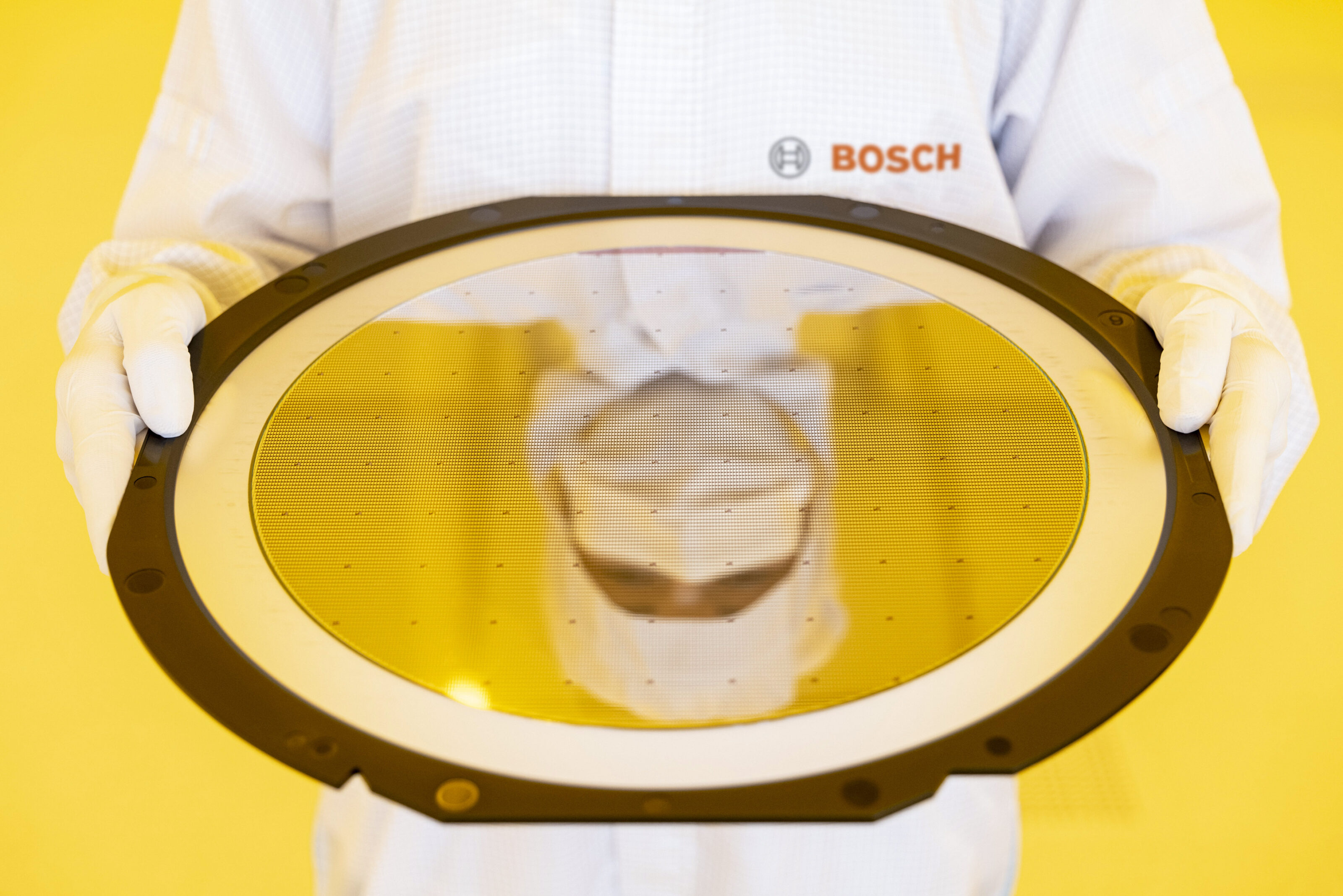

The Dresden factory will be manufacturing 300mm wafers, the base of the semi-conductor chips, which will then be sent on to other facilities in Asia to be assembled and distributed to automotive manufacturers.

Bosch say it takes around 20 weeks to make a semi-conductor chip, with over 600 steps in the wafer making facility alone.

Both Nissan and Stellantis announced last week they would be temporarily closing down their automotive plants throughout June due to a lack of stock, while Hyundai Australia confirmed it had halted plans to bring a new i30 Down Under due to the shortage.

We recommend

-

News

NewsGlobal semi-conductor shortage not an ‘issue’ for Toyota

Toyota Australia VP says clever planning has fortified the Japanese marque despite the tech shortage

-

News

NewsSemi-conductor shortage leads Nissan and Stellantis to suspend production in Mexico

Four Mexican manufacturing plants will be suspending operations this month as the global semi-conductor shortage grinds production to a halt

-

News

NewsThis is how much money car manufacturers make every second

Volkswagen’s annual revenue exceeds the average Australian’s salary every five seconds