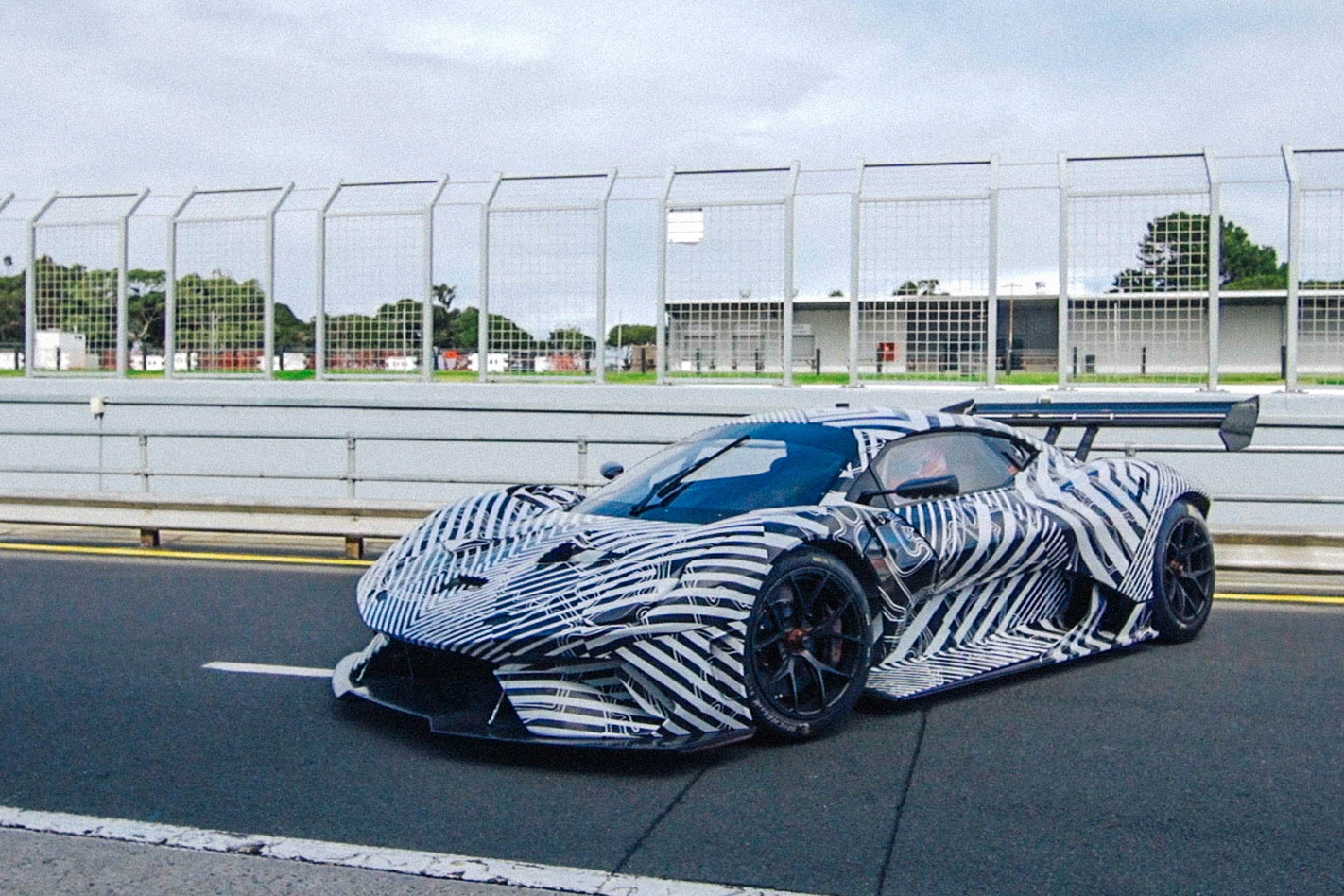

THIS is the Brabham BT62. It is not a concept car. It is not a hypothetical rendering years from production. It is here, now, as a fully formed supercar customers will take delivery of before the year is out. And the best bit? It’s built right here in Australia, by Australians.

Here are the headline numbers: 5.4-litre naturally aspirated V8, 522kW at 7400rpm, 667Nm at 6200rpm, 972kg dry. It is an all-out attack on the track-only toys from the likes of Ferrari’s FXX program, and even the McLaren Senna GTR, and has the esteem of a marque etched into Formula 1 legend.

Brabham’s re-emergence has been shrouded in secrecy since the family won a court battle to protect the name in early 2013. The BT62 project has been on the boil behind closed doors for the last two years. Brabham is one of the most evocative names in motorsport, with intrinsic Australian DNA, and its return to the automotive landscape has been extremely calculated in execution. Managing it is respected racing driver – and youngest son of Sir Jack – David Brabham, and a team of businesspeople split between Australia and the United Kingdom.

Christian Reynolds is one such businessman. He’s an ex-pat working in Adelaide as both a Brabham Automotive director and representative for Fusion Capital Partners, a private equity firm that has backed the initial phase of Brabham’s return.

“[Fusion Capital was] looking at the opportunity in this market in late 2015. We were fairly well through mature concept planning, and through mutual contacts we were introduced to David. It snowballed pretty quickly from that point. We started working through how we could align what we saw in the market with the revival of the Brabham brand, and set out how we would work together to deliver a program like the BT62.”

Brabham tells Wheels: “When we first met we started to talk about visions. I said, ‘I’m either involved or I’m not.’ For me this was all hands on deck. If we’re producing a high-performance vehicle it’s got to have Brabham DNA in it.”

Reynolds is the man overseeing the 15,000sqm production facility in an undisclosed Adelaide suburb, keeping engineering and operations teams on schedule. His employment history reads like a who’s who of lightweight performance experts and disruptive business pioneers including Lotus and Tesla.

Before Brabham Automotive, Reynolds was managing director of ZF’s Australian arm, with a direct line into Holden through the axle and chassis work undertaken by the firm for General Motors. His exposure to the manufacturing industry in South Australia primed him to leverage our existing expertise and infrastructure, and to bring the right people in from local OEMs, third-party suppliers and even Supercars race teams. “The supply base and the capability has always been here to develop advanced product. In both advanced manufacturing and advanced engineering it’s actually quite a logical choice to use that installed capacity and supply base.”

Brabham agrees. “It’s a fantastic opportunity with manufacturing having left these great shores. There’s a bit of a void with a lot of well-trained, talented engineers and people. A project like this can tap into that,” he says.

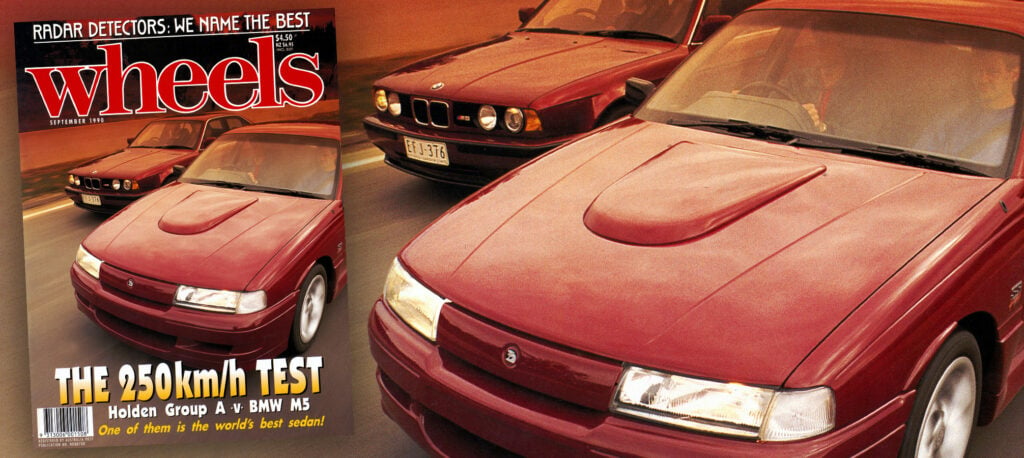

On paper there’s no immediate link between Australia’s history of building large sedans and a high-end track-focused supercar carrying a A$1.8m price tag. And the Brabham couldn’t be further from a Commodore or Falcon.

Composite materials feature heavily, including extensive use of carbonfibre for the main body panels, the floor and barge boards, and all aerodynamic additions. Carbon-Kevlar is used for the wheel houses, and it is pure racecar everywhere else. Double-wishbones with adjustable pushrod-actuated Ohlins dampers hang off each corner. There’s an air-jacking system, dry-break fuel fillers in the rear quarter windows and on-board telemetry data acquisition.

Stopping power comes from enormous carbon-on-carbon six-piston Brembo brakes – 380mm front, 355mm rear. The gearbox is an Australian-made, air-shifted Hollinger sequential with six forward ratios that sends drive to the rear wheels from the dry-sumped Brabham-branded 5387cc quad-cam V8.

Pressed for details about the engine, Reynolds is frustratingly reluctant to share. He is instead keen to point out the BT62’s powerplant is vastly different from anything available off the shelf, and is Brabham in personality as much as in spec.

A little digging suggests the base engine is sourced from Ford, and most closely related to the 5.2-litre ‘Voodoo’ V8 with flatplane crankshaft found in the Shelby GT350 and GT350R, itself a development of the 5.0-litre ‘Coyote’ V8 that powers the regular Mustang.

“We engaged an OEM and talked to them about a personalised development program,” says Reynolds. “They were supportive at that level, but we took the engine and heavily customised it to suit the attributes of our vehicle and agreed with the OEM that the engineering work is such the engine can be called a Brabham based on its departure from anything they do in any sector of automotive.

“We’ve customised and re-engineered it to be very, very specific to this vehicle. The design specifications are under control of Brabham. You cannot go out and procure an engine of this configuration.”

Brabham adds they didn’t simply grab the first V8 they could find. “There’s a strategy behind it,” he says. “We’ve got racing in our sights. A lot of the architecture we’ve done around the car and the engine is based around where we want to go with that.”

Push for clarification about which category the BT62 will compete in and Brabham’s representatives are cagey, though the official line is, “Le Mans is in our sights.”

A focus on the racetrack means aerodynamic performance is paramount. Sculpted bodywork scoops air around the purpose-built chassis, applying downforce via blades and canards and an adjustable dual-element rear wing optimised using computational fluid dynamics.

Again, more secrets surround the source of the car’s emotive design. Reynolds cites the support of a ‘well-respected international partner’, but there’s no namechecking when pressed for specifics.

Elements of its form resemble themes seen in other high-performance vehicles from McLaren and even Lamborghini that have a focus on air management, though as a whole the BT62 is far from derivative.

“What you see in the finished vehicle is the battle between form and function,” says Reynolds. “We’re re-establishing the marque, so there are subtleties in the design in terms of the taillights, door depth to sill position, that will continue to identify brand vehicles going forward.”

“It has an identity of its own, which is really important,” says Brabham. “Those design cues will flow through the next variant of cars so you’ve got that common thread and it becomes ‘that’s a Brabham’.”

But track-only supercars are not the only goal for Brabham Automotive. The BT62 is a means of establishing credibility. Beyond racing as the next step, the eventual target is street-legal road cars.

“Aspirationally we understand where we want to end up, and we’ve entered this venture with a long-term business plan,” says Reynolds. “It’s fair to say we have to earn the right to grow, and we believe BT62 is the right product to re-establish the brand and give people confidence in the validity of the company.

“The automotive industry will see a growth in what we refer to as A-to-A vehicles. Whether that be on the road or out on track. We’ve developed a platform structure that will lead us toward competition.”

“We have the team in place that has engineered the first vehicle, we are in the mature concept phase for the follow-on vehicle, and specification ready on the third generation after that,” says Reynolds.

Presently, Brabham Automotive operations are divided into two main camps, with a core team in Australia responsible for delivery of the physical project, and a crew in the UK charged with technical engineering and sales.

Mystery surrounds the exact scale of the fledgling enterprise in terms of personnel and the depth of talent at its disposal. Specifics are being kept behind a curtain, for now, but there is a clear roadmap laid out beyond BT62’s launch and the people to deliver it, according to the company.

“We don’t really want to say how many people are in the business. We’ll disclose how big we are later on for you to understand the true horsepower behind this venture,” says Reynolds. “We’ve gone two and a half years being very comfortable not telling people everything that we’ve done and who we are, and that’s part of our continued plan going forward.”

The development program has seen the car tested at several Aussie locations, including Phillip Island Grand Prix Circuit where it’s understood the brief was to achieve a 1:22.0 – an outright record – making it nine seconds per lap quicker than a V8 Supercar. Brabham won’t say whether that target has been met. Not because they didn’t time it, but because it represents yet another ace tucked up its sleeve for drip-feeding.

The Brabham BT62 is the most ambitious, most expensive production car this country has ever produced, and most likely the fastest. Whether it can deliver on the performance promise, and successfully command its phenomenal asking price against brands with established credentials remains to be seen, but on paper, this is no flash in the pan. Brabham is back.