You all know the clichés. Hell, you may have even repeated them a few times. Electric cars are fast, but heavy. With all the extra heft of the batteries, EVs are the super heavyweights of the performance car world. Rimac Nevera – 2000kg. Tesla Model S Plaid – 2162kg. Porsche Taycan Turbo S – 2295kg.

Of the electric hypercars, Lotus’ Evija claims to be the lightest at just 1680kg. Less than rivals sure, but not exactly living up to the Jenny Craig-inspiring principles of Colin Chapman. With this in mind, when it was announced that the replacement for the current Lotus Elise and Exige models would be fully electric, there were understandable concerns about weight.

Well, Lotus engineers have been hard at work for the last year developing a new platform for the next-gen products, going to extreme lengths to ensure weight (and dynamic purity) is appropriate. What they have created is dubbed the E-Sports chassis.

This brand new blank sheet design is the end result of Project LEVA, which stands for Lightweight Electric Vehicle Architecture. The program was announced late last year, and will debut with the Type 135 (an as-yet unnamed sports car to replace the Elise).

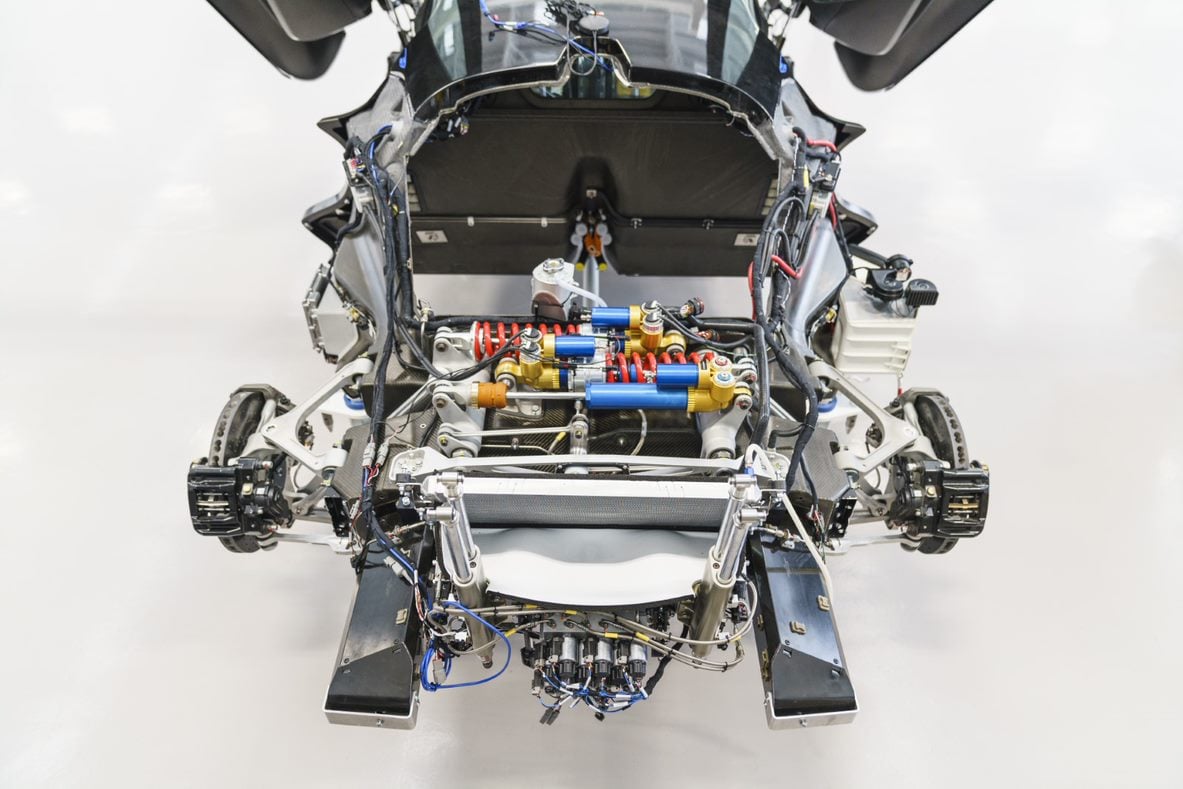

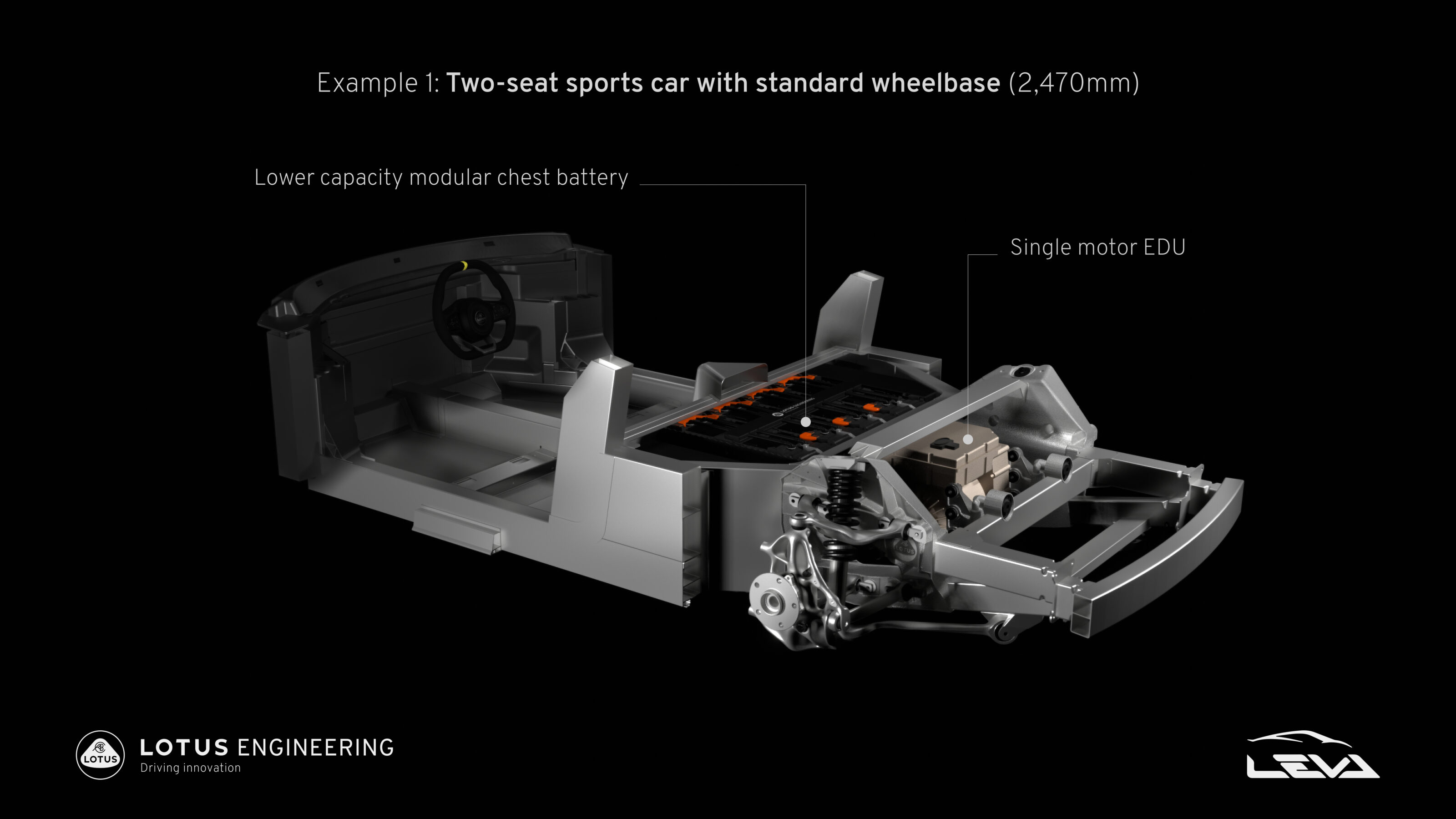

Key to the weight saving are unique subframe structures, with Lotus claiming the rearward unit is 37 per cent lighter than that used on the V6 version of the Emira. The aluminium chassis uses a die-cast rear sub-frame with interchangeable components to ensure modularity (more on that later), while the battery pack is housed within the core bodyshell instead of building a separate container which is then added to the chassis.

Instead of bolting the front and rear subframes to the chassis, Lotus uses lighter bonding and riveting alternatives, with the structure designs themselves built using a new low-pressure die-casting process (essentially injecting liquid metal into a steel mould).

Die-casting is traditionally done at high pressures, but the new technique allows for the structure to have greater detail, while Lotus’ choice of aluminium alloy means crash structures are more pliable.

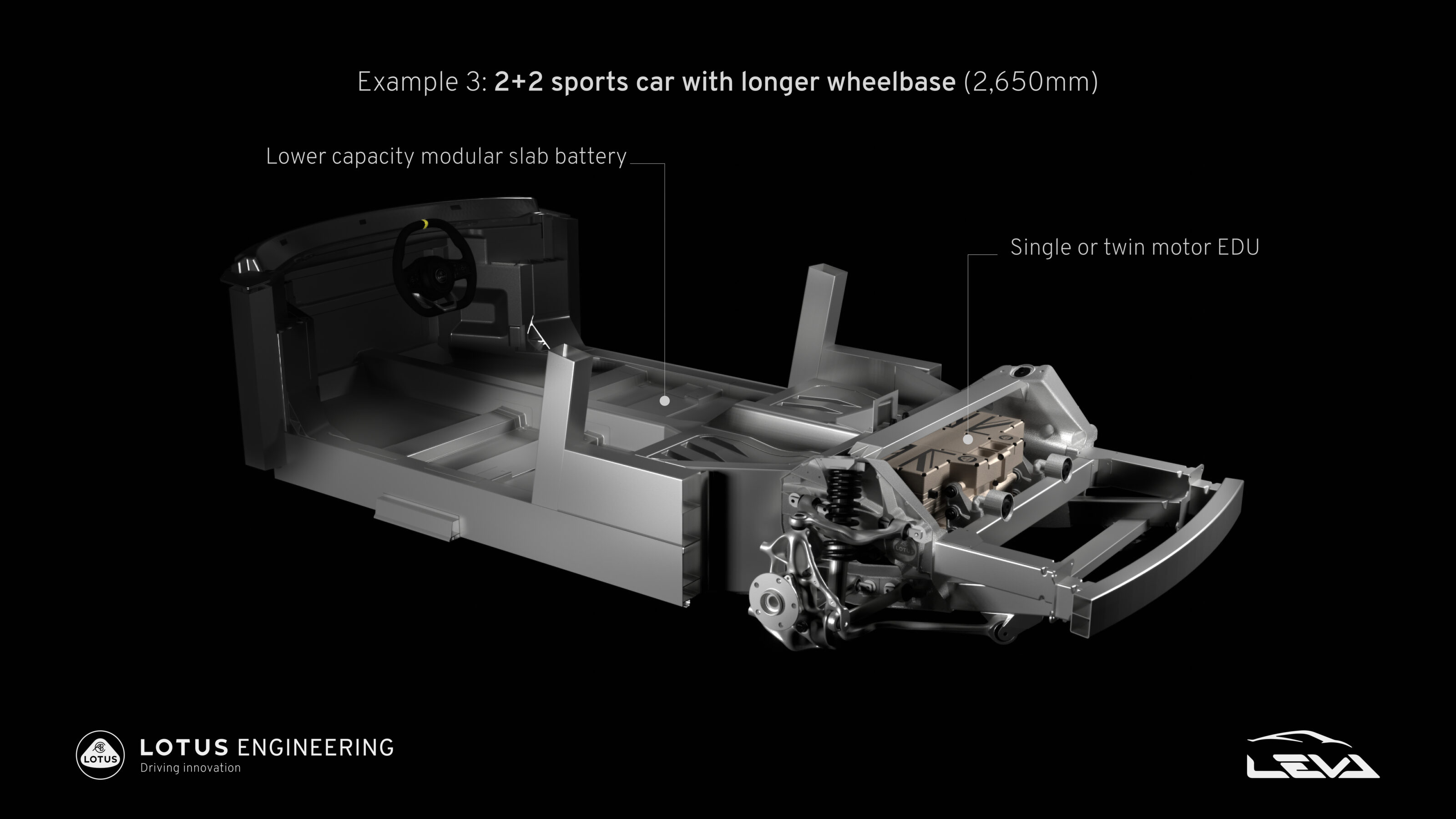

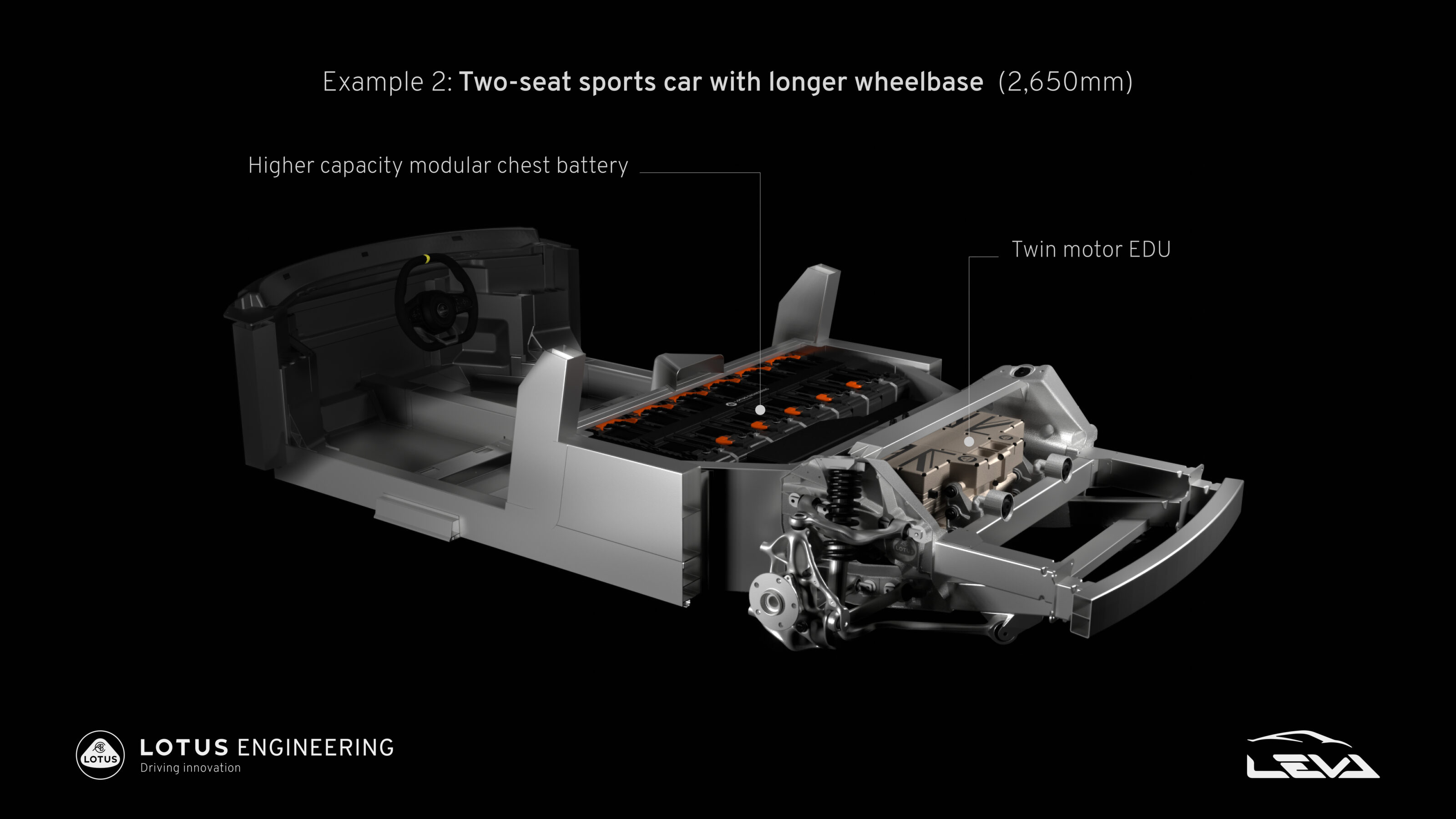

Modern manufacturing and product planning demands the new architecture be modular, and Lotus has delivered. Possible wheelbase lengths range from 2470mm to more than 2650mm, accommodating both 66.4kWh and 99.6kWh batteries in either a ‘slab’ or ‘chest’ layout, both pure two-seat and 2+2 interior designs, with single and twin motor formats.

The ability to accommodate two different battery layouts in a single chassis design is one of the big innovations of Project LEVA. It is akin to an ICE chassis being capable of both front- and mid-mounted engines. Of those layouts, the slab will be most familiar to MOTOR readers, with the design also referred to as a ‘skateboard’.

It is an incredibly popular format for EVs, and its centre of gravity benefits are undeniable, but is flawed when it comes to capturing and maintaining the driving spirit of the Lotus brand. Anyone that has driven a Lotus will tell you, the low hip point is central to the entire driving experience. As a result, simply placing the batteries underneath the floor wasn’t going to cut it for two-seater models that will use the E-Sports chassis.

Enter the ‘chest’ where the batteries are stacked behind the seats, mimicking the mid-engine layout of many combustion-powered vehicles. This design allows for the driver to sit 100mm lower, with the overall vehicle profile dropping by a similar amount. Lotus intends to use cylindrical battery cells for higher energy density, along with an 800V electrical system to work alongside the fastest charging infrastructure.

The head of Project LEVA, Richard Rackman, claims the E-Sports Chassis lives up to the fundamental spirit that defined the Lotus Elise in 1996, while allowing the company to thrive in an electric future.

The Type 135 will not debut in the flesh for some time yet, but Lotus’ commitment its to core brand fundamentals in a changing market gives the lie to those cynics predicting that an electric Elise replacement will have Colin Chapman turning in his grave.

Partnered up

Lotus hasn’t been working entirely on its own in creating the E-Sports chassis. The manufacturer’s existing supply chain partners Sarginsons Industries, along with academics from Brunel University in London, were brought onboard Project LEVA to “harness the full light-weighting potential of the vehicle architecture”.

Agility > Pace

Lotus says cars using twin-motor versions of the E-Sports chassis will be capable of producing 650kW, with single drive-unit variants coming in around 350kW. However, while those figures are impressive, engineers are focusing on overall agility and driver enjoyment rather than trying to build a vehicle to claim victory in a game of spec sheet top trumps.

The man pulling the LEVAs

Richard Rackham, the head of Vehicle Concepts at Lotus, has been leading Project LEVA since it was first revealed in October 2020. His work on the program is significant, as it gives the architecture a direct link back to the Elise, as Rackman is best known for his work developing the extruded aluminium architecture for the Type 111.

French Connection

The fruits of Project LEVA will be offered to other manufacturers – at a price – via sister company Lotus Engineering. Alpine is currently the first to take up the offer, working alongside Lotus on chassis development with an eye to use the architecture for the A110 replacement. Lotus MD Matt Windle has already suggested the Alpine sibling will have a shorter wheelbase than the Type 135.