Toyota’s plan to become a global leader on solid-state batteries seems to be gaining momentum, with an executive from India claiming the company will introduce the new tech “in a couple of years.”

Toyota currently trails its rivals when it comes to EV production and sales — competitors like Tesla, BYD and Volkswagen are all ahead of the Japanese giant — yet it sees solid-state batteries as an opportunity to regain lost ground.

Promising faster charging times, better performance and longer battery life, solid-state batteries should also lower the purchase price of electric vehicles, leading many to tout them as the next great leap in EV powertrains.

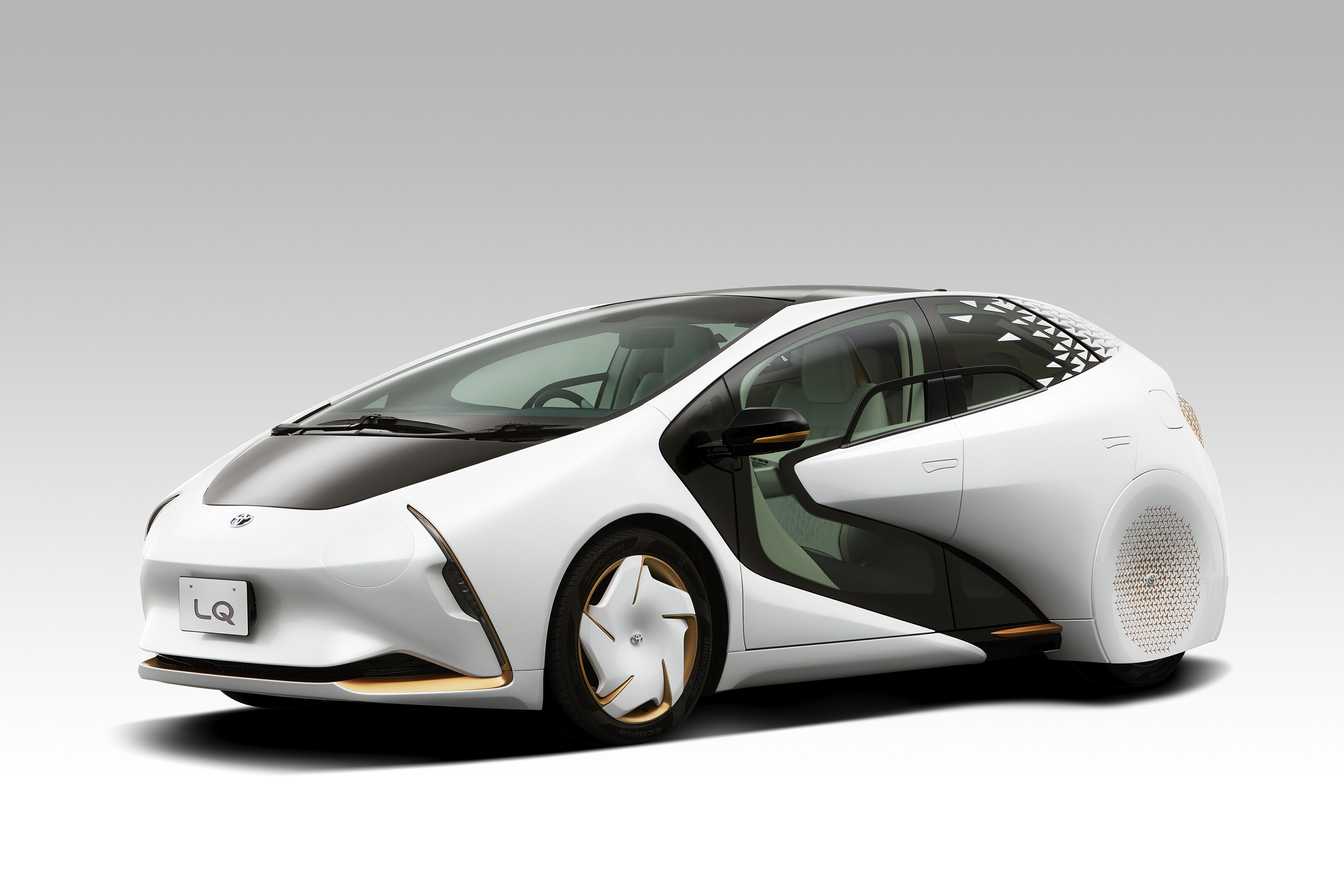

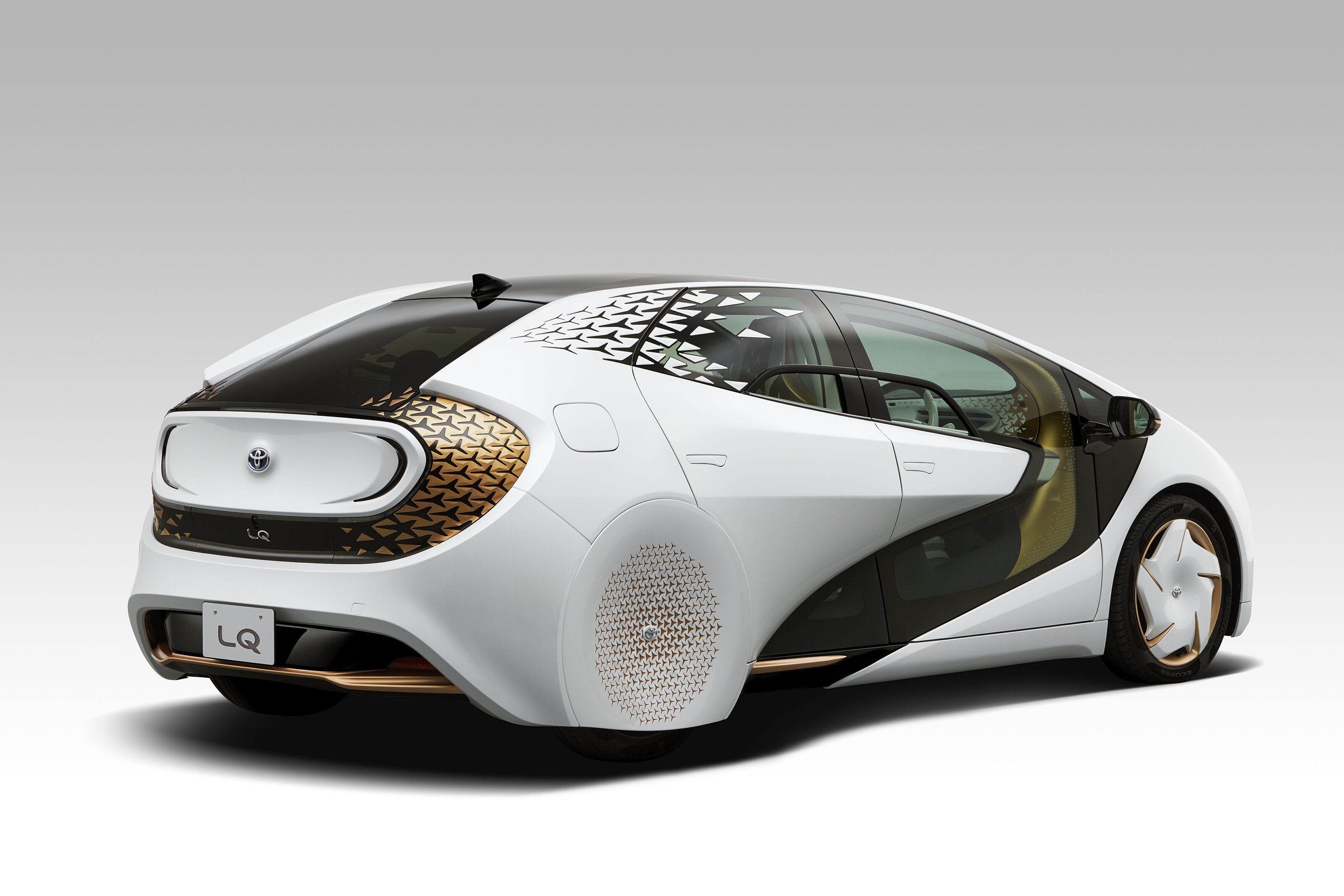

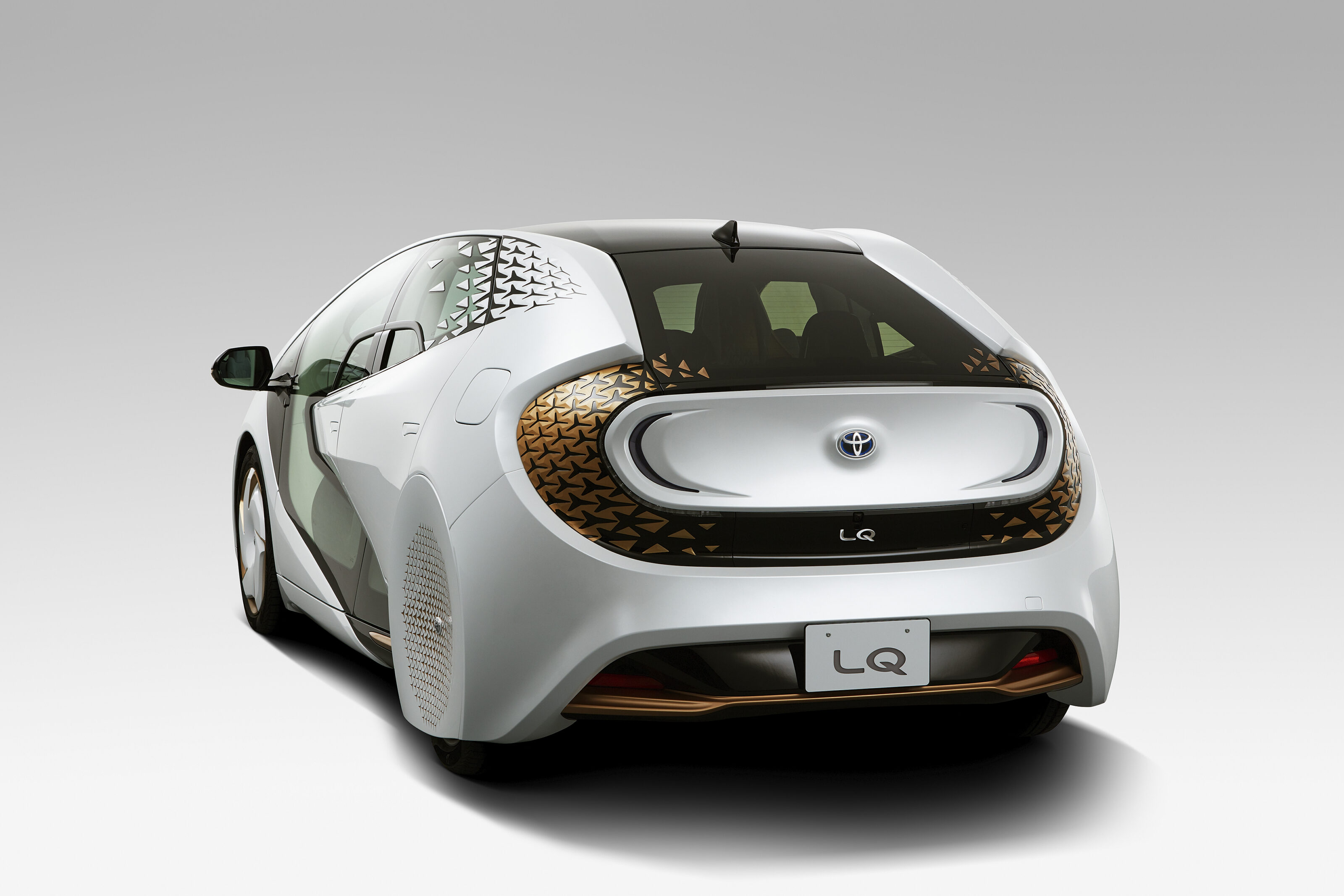

“We will be rolling out our electric vehicles with solid-state batteries in a couple of years from now,” said Vikram Gulati, India’s head of Toyota Kirloskar Motor. “It will be a vehicle which will be charging in 10 minutes, giving a range of 1200km and life expectancy will be very good.”

Toyota isn’t the only brand developing solid-state batteries, of course. Hyundai, Kia, Volkswagen, Honda, Tesla and Mercedes are just some of the rivals investing heavily in the new battery tech, yet Toyota is quickly proving to be ahead of the curve.

Gulati’s comments were made at the Vibrant Gujarat Global Summit and it’s worth noting his suggested timeframe is much earlier than previously indicated. Until now Toyota has said it is aiming to achieve mass production of solid-state batteries towards the end of the decade.

In September last year, Toyota revealed its ‘advanced battery technology roadmap’ which mentioned a “breakthrough in sold-state battery technology”. At the same time, Toyota announced it had teamed up with Japan’s second-largest oil refiner, Idemitsu Kosan, to develop and mass produce solid-state batteries, with the partnership aiming to introduce the new batteries in 2027 and 2028.

Why solid-state batteries are the holy grail

If you could own an electric vehicle that could travel more than 1000km on a single charge, retained nearly all its battery capacity after three years, can operate normally in a wide range of temperatures, could be recharged in 10 minutes, and cost the same as an equivalent combustion-powered car, would you?

That is the situation that will be thrust upon consumers when solid-state battery technology begins being mass produced midway through this decade. Toyota is hoping to get ahead of the curve, pushing a number of solid-state battery electric vehicle prototypes into service with the aid of partner Panasonic.

With more than 1000 patents relating to solid-state tech, Toyota is putting most of a $18.7 billion investment toward its advancement and eventual large-scale production. It’s not hard to understand why. The benefits of solid-state batteries over current lithium-ion designs are clear cut. Solid-state units are safer, have a higher energy density, reduce both size and weight, and can operate in a wider temperature window.

Lithium-ion batteries use a liquid electrolyte solution that if not properly managed, or is damaged, can swell in size or spontaneously combust. These events are rare, but they do occur. With certain lithium-ion batteries, as much as a third of the storage capacity can degrade after a decade.

In both battery designs the electrolyte is a chemical mixture that allows current to travel between the cathode and anode (or more simply the positively and negatively charged electrode respectively). In lithium-ion batteries this separator is a liquid solution, where a solid-state battery uses a solid electrolyte.

Liquid electrolytes are what cause those spectacular and hard-to-dose fires when things go wrong. Solid-state alternatives alleviate all these issues and bring a massive increase in the amount of power that can be stored within a battery. This gives manufacturers two options; reduce the size of a battery, saving space and weight with no loss of energy, or retain the current dimensions with a boost in outputs.

The fact that a solid lithium metal anode increases energy density has been known for nearly half a century, but it is only now that we have had the technology to make it a reality. That’s because using lithium metal with a liquid electrolyte has a risk of creating stalagmite-like formations that can puncture the separator between the anode and cathode which results in a nasty chemical explosion.

A variety of solid-state electrolytes are now available that work as a ceramic separator and have the same conductivity without the risk of exploding.

A prototype non-automotive solid-state battery from Samsung has an energy density of 900Wh per litre, while the very best lithium-ion units are only capable of roughly 700Wh per litre. The company says using this in an electric vehicle would allow the car to travel up to 800km on a single charge. With a life cycle of 1000 charges that puts the battery’s lifespan at 800,000km. Your uncle’s LandCruiser might struggle to match that.

Going even further, US-based QuantamScape, of which Volkswagen has a 5 per cent stake, released a study late last year that demonstrated its solid-state battery cells have an energy density of more than 1000Wh/L.

On top of that, it was shown the batteries can charge to 80 per cent capacity in 15 minutes, while retaining more than 80 per cent of its capacity after 800 charge cycles. The secret? Pure lithium metal as the anode. A production-spec version of the battery isn’t expected until 2024.

Toyota’s claims are simple. Twice the range of an equivalent lithium-ion unit, while retaining 90 per cent of its performance after 30 years. Continuing its bold claims, Toyota says its solid-state batteries will be capable of charging from zero to full in just 10 minutes. Toyota says its solid-state battery won’t hit mass production until 2025.

Like others in the solid-state arms race, that’s because while the technology is almost ready for large scale use, the production capacity isn’t there yet. Unlike current batteries, solid-state units require different machinery and techniques in the manufacturing process. Additionally, simply not enough raw lithium is being produced – of which the world has a finite amount (see breakout).

Toyota also has a government-funded advantage. Japan’s government has created a ¥2 trillion (A$24.7 billion) war chest which it is using to fund manufacturers’ efforts in creating new decarbonisation technologies. A large portion of the money will go toward solid-state batteries, in particular acquiring the lithium needed. Additionally, two Japanese mining and oil companies, Mitsui Kinzoku and Idemitsu Kosa, are building infrastructure to produce solid electrolytes.

This is all in an effort to gain an advantage over China and South Korea in the battery production arms race, with the global market for next-gen tech that outguns current lithium-ion designs expected to grow in value from $53.6 million a year to $34.6 billion in 2035.

Why the rapid expansion? You, the average car buyer. In 2035 you’ll be faced with that dilemma that started this, and there are big players betting they know which option you’ll choose.

Seeing glass

The University of Bayreuth is working with Tesla Germany and Varta Microbattery to develop lithium-ion battery separators made of glass. The project dubbed GlasSeLIB (meaning glass separators for lithium-ion batteries), hopes to use glass electrolytes instead of ceramics to increase the safety and service life of lithium-ion batteries.

The hybrid dilemma

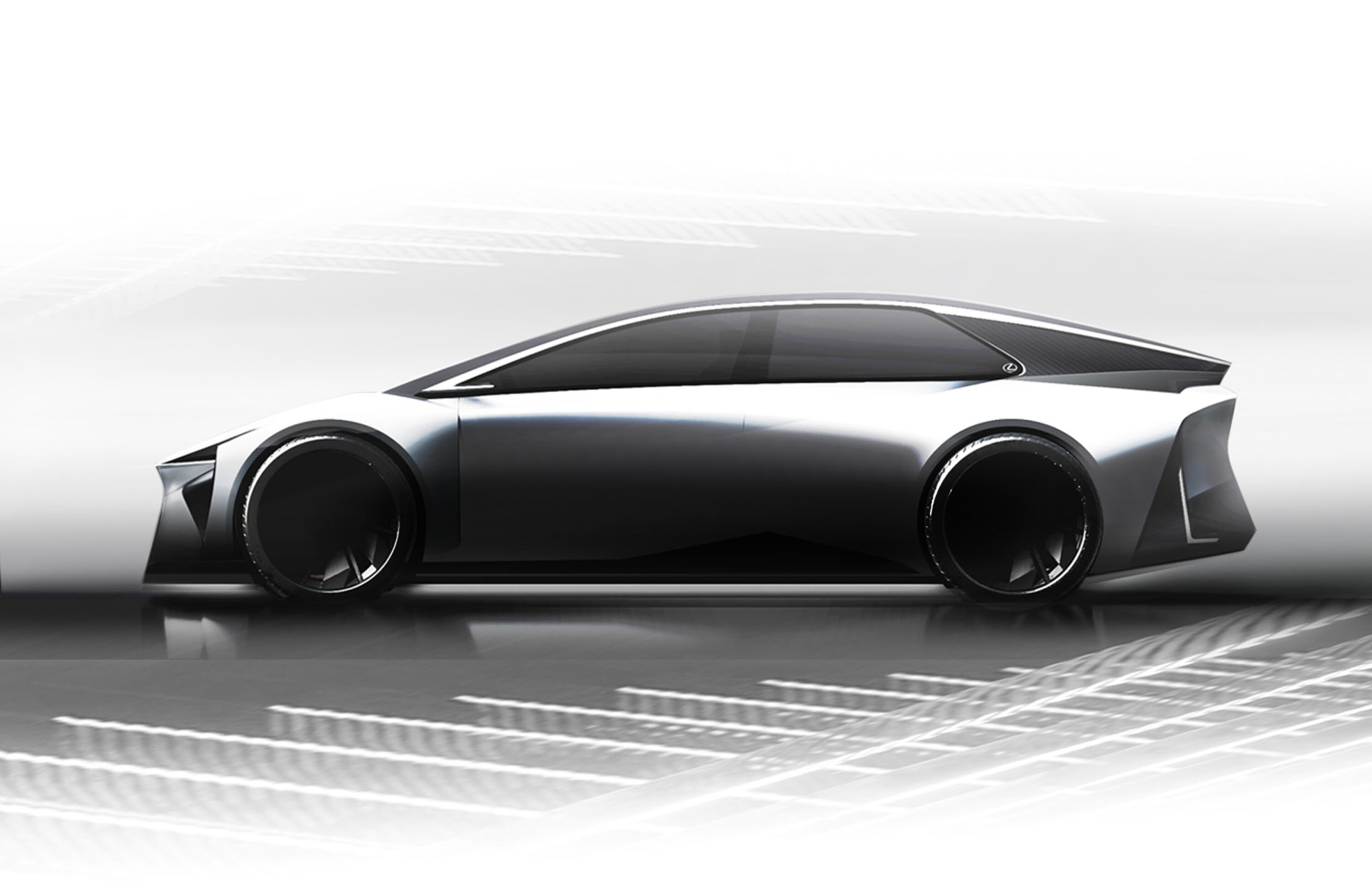

Toyota has copped plenty of flak for dragging its feet on full battery electric vehicles – opting instead to favour traditional hybrids. In response, the manufacturer says its 18.1 million hybrids produced so far are responsible for the same carbon dioxide reduction impact as 5.5 million BEVs, while using the battery components needed to build just 260,000 BEVs. That said, by 2025 Toyota promises to have 15 different BEVs in production.

Nickelpack

Despite the focus on solid state batteries, Toyota hasn’t completely abandoned lithium-ion or nickel-metal hydride designs. Its that latter which the Japanese brand has recently announced a breakthrough with, creating ‘bipolar electrodes’ that allow for the battery to shift from a group of separate cells to a single stack. The new design can fit 1.4 times the amount of cells, producing 1.5 times the power compared to previous gen nickel-metal hydride batteries.

Mine craft

Regardless of design, batteries for EVs require the use of lithium, of which there are only 80 million tonnes of reserves identified globally. Bolivia sits atop the largest lithium reserves with 21 million tonnes, ahead of Argentina (17m), Chile (9m), the USA (6.8m), and Australia (6.3m).

In 2019 we were the largest exporter of lithium in the world, with 42,000 tonnes being shipped overseas that year, most of it going to China (who has the sixth largest reserves at 4.5m tonnes). The next biggest exporter was Chile, which offloaded 18,000 tonnes.