Since Karl Benz’s Patentwagen chuffed out of the shed that birthed it, there has always been one constant in the world of automobiles: every component, no matter how minor, has been designed by an engineer.

General Motors wants to change that.

But not because the company wants to put engineers out of work. Rather, it’s just that when it comes to designing parts that serve a purely functional purpose – in other words, parts that don’t need to look good – a computer actually does a better job of designing something that’s strong, lightweight and uses the minimum amount of raw material to fabricate.

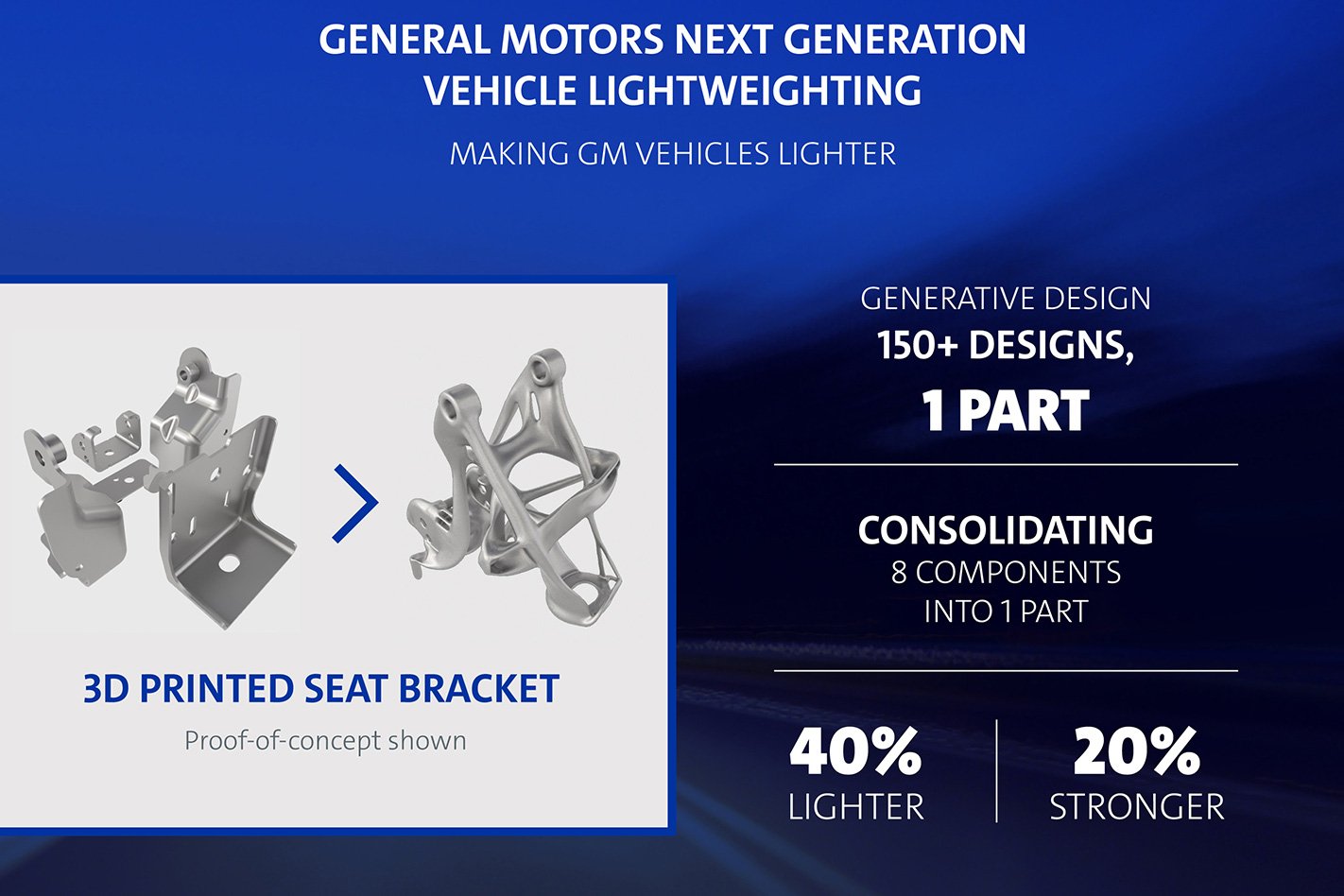

It’s called generative design, and it uses artificial intelligence to create shapes that are as strong and light as possible. General Motors has paired up with engineering software giant Autodesk, and the first fruit of its AI-powered generative design experiment is the most elaborate, intricate seatbelt bracket you’ve ever seen.

Its thin, web-like structure looks more organic than mechanical, but is otherwise functionally identical to the human-designed stamped steel part that it’s intended to replace. The hard points are the same and it fits in the same space as the original part. The major difference is that it’s both 40 percent lighter and 20 percent stronger than the stamped steel bracket, and made of one solid piece of metal rather than eight steel pressings spot-welded together.

And besides having a human operator specify things like what size bolt holes were required, the positioning of mounting points, the type of material and where material shouldn’t be placed, the actual design process is entirely automated. Autodesk’s software spits out a multitude of potential designs, (in the seat bracket’s case, over 150-plus were generated) of which GM engineers select one.

The only issue is that due to the physical complexity of the resulting part, the only suitable manufacturing method is 3D printing – which at this stage is still too costly for mass production.

But it’s early days for GM’s foray into AI design. The company has embarked on a mission to cleave weight from its cars, and in the US market it has launched 14 all-new models over the past two years that boasted average weight reductions of around 160kg. With GM’s aggressive weight-saving agenda, an AI-designed production car – or at least AI-designed production car components – isn’t such a sci-fi concept anymore.