The Australian Automotive Aftermarket Association (AAAA) has officially opened the first of two new state of the art Automotive Innovation Centres in Victoria.

That means local businesses who sign up as AIC members can gain access to a fleet of vehicles as well as a perpetually-increasing portfolio and catalogue of extensive 3D models and data from which they can design, prototype and test new components for the Australian market - all with the in-house assistance and expertise of the AIC.

By having access to a huge library of digital design data, the goal of the AIC is to help speed up development of vehicle-specific aftermarket parts, be they bullbars, bodykits, or cupholders.

The Melbourne location (situated in Mulgrave, south-east of the city) was launched last week, and is the first of two intended AICs; the second of which will be based in South Australia with operations beginning in 2020. Heavily inspired by SEMA Garage in the United States, the AIC model seeks to mirror the success of its American counterpart.

The AIC was originally conceived back in 2014 and is backed by $10 million in government funding, and seeks to maintain and elevate Australia’s aftermarket industry on the global stage in the current post-manufacturing era. And with seemingly every Toyota Hilux and Ford Mustang sporting at least one aftermarket modification these days, there's plenty of potential business in Australia alone.

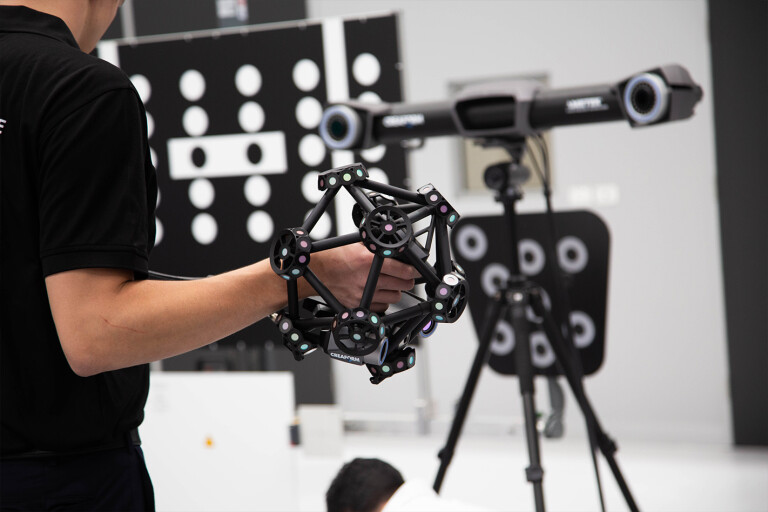

Beyond its cutting-edge 3D scanning technology and 3D printing capabilities, the Melbourne AIC boasts an extensive metal fabrication room, radar and sensor calibration, vibration testing; and the in-house ability to carry out dynamic testing of brakes, ESC and other advanced driver assists.

The facility is fully-outfitted with industry-leading equipment and ready for full operation. Complete with machinery, lifts, hoists and tools provided by many of the AIC’s sponsors. For small businesses who don't have the capital to buy such equipment themselves - and hire the specialised workers to operate it - an AIC membership could be a game-changer.

Continental tyres is providing control tyres for all dynamic testing, and provides a unique partnership by supplyingextensive tyre data from their headquarters in Germany. It's a symbiotic arrangement, with Continental using the AIC to help carry out conclusive dynamic testing via computer simulations, and ultimately saving the time intensive (not to mention costly) process of mobilising automated in-car tests at a closed race track.

Beyond the technical facilities the AIC has to offer, it’s also positioned itself to provide a key role in automotive education and training for the next generation of industry workers, with a dedicated 100-person training room overlooking the workshop.

Not just influenced and inspired by the US SEMA Garage model, the two firms have engaged in a data-sharing partnership, with the AIC gaining access to CAD data of various US-domestic vehicles already gathered by SEMA Garage. For local aftermarket firms looking to produce accessories to cater for the increasing appetite for full-size American pickups such as Nissan’s Titan and RAM’s line of trucks, that data will be a godsend.

In the future, the AIC also aims to mirror SEMA Garage’s relationships with OEMs, who could provide pre-production vehicles to be scanned in advance of their market launch, allowing local aftermarket firms to have products and accessories on the shelf as soon as a car enters showrooms.

“This is a fantastic new facility for the industry, so we welcome companies contacting us to discuss how the centre can directly assist their business” said AIC Managing Director Luke Truskinger.

The AAAA has big ambitions for the AIC, but in the current post--car-manufacturing climate; should be a valuable asset in increasing the competitiveness of Australia’s inventive aftermarket industry on the global stage.

COMMENTS