Car design is growing ever more complex. But, as the world leans more and more on new technologies to innovate, digital tools and raw computing power can be used to the advantage of modern car designers.

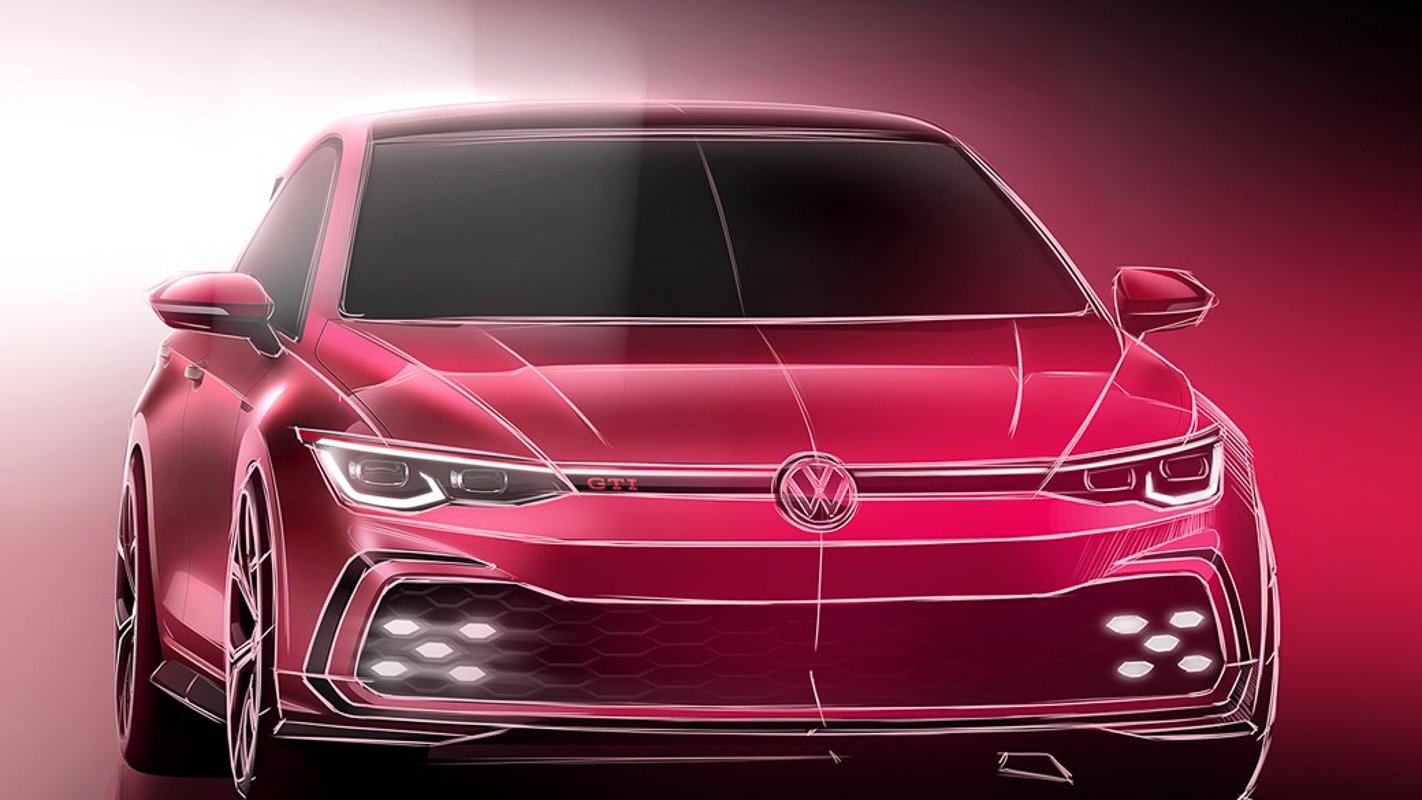

Take Volkswagen, for example: its latest Golf hatch was almost entirely designed using computers and programming rather than a sketch pad. Klaus Bischoff, head of design for the Volkswagen Group, describes to us how new technologies have sped up, simplified and even enhanced the car design process from the very early stages.

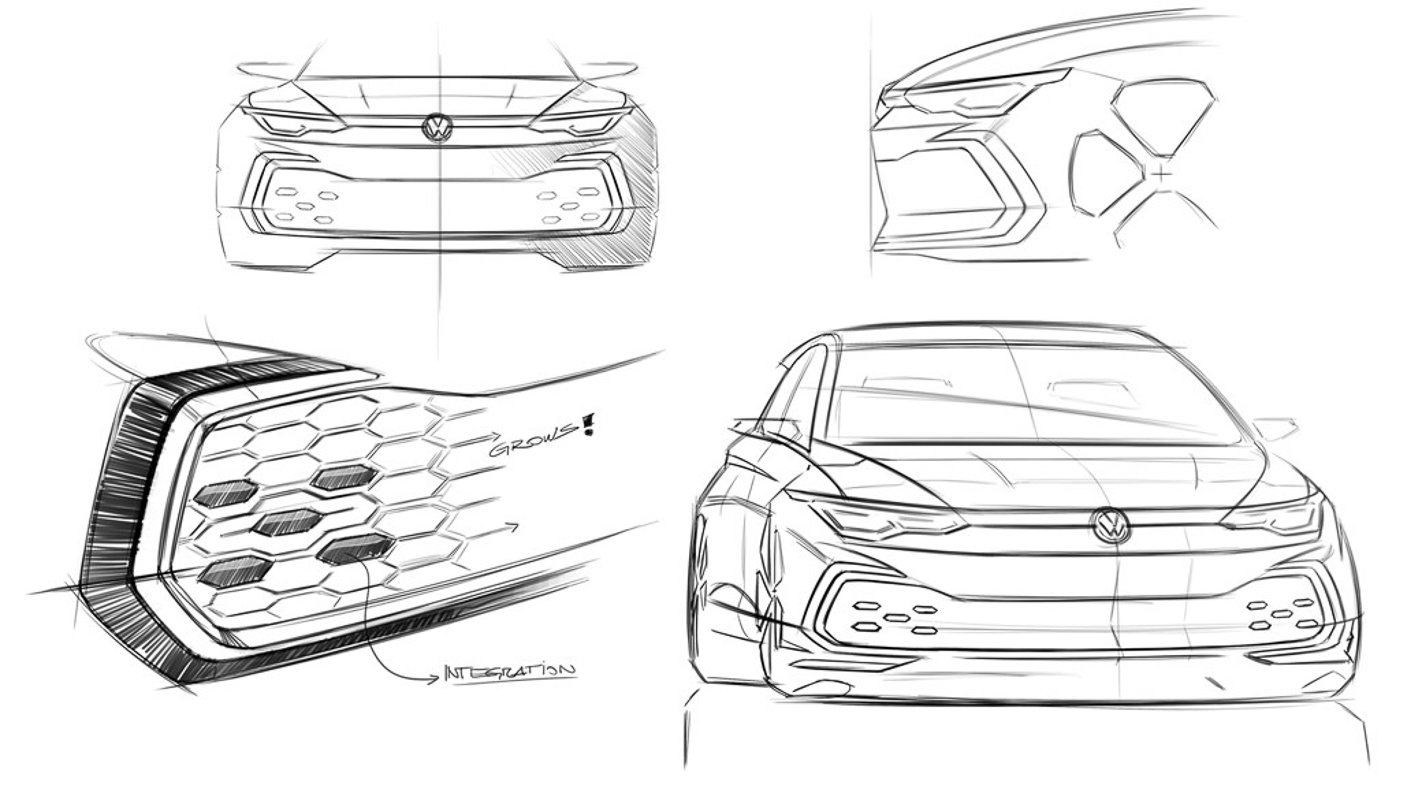

Sketches, for example, are almost entirely done using digital sketch pads with tablets and computers rather than old fashioned pencil and paper. ‘The advantage in digital sketching is that you can erase, colour, zoom in and out and use multiple tools in a single workflow to create what you’d like to show,’ Bischoff says, ‘I myself work with digital sketchpads to draw up ideas quickly and share them. What, a few years ago, took hours can now be done in minutes.’

So it’s all digital now?

Of course not – designers in the VW Group still sculpt clay models, for example, but computer programs have allowed design teams to test out ideas and try new perspectives much faster.

‘Data is not tangible so, up to a certain degree for the final touches of the product, you need to have physical representations,’ adds Bischoff, ‘a model is still a very valued instrument.’

These tools are also hugely collaborative. Bischoff explains that, because the Group has around 415 designers of 30 nationalities across the world, telecommunications equipment has meant teams can work together around the globe. ‘Everyone can see what their colleague is doing and you can show whatever you like or dislike,’ he points out, ‘comments can be implemented and shown. For us, as we work on different continents, this is a very useful tool.’ It also has put the Group’s design teams at an advantage when it comes to the ongoing coronavirus pandemic.

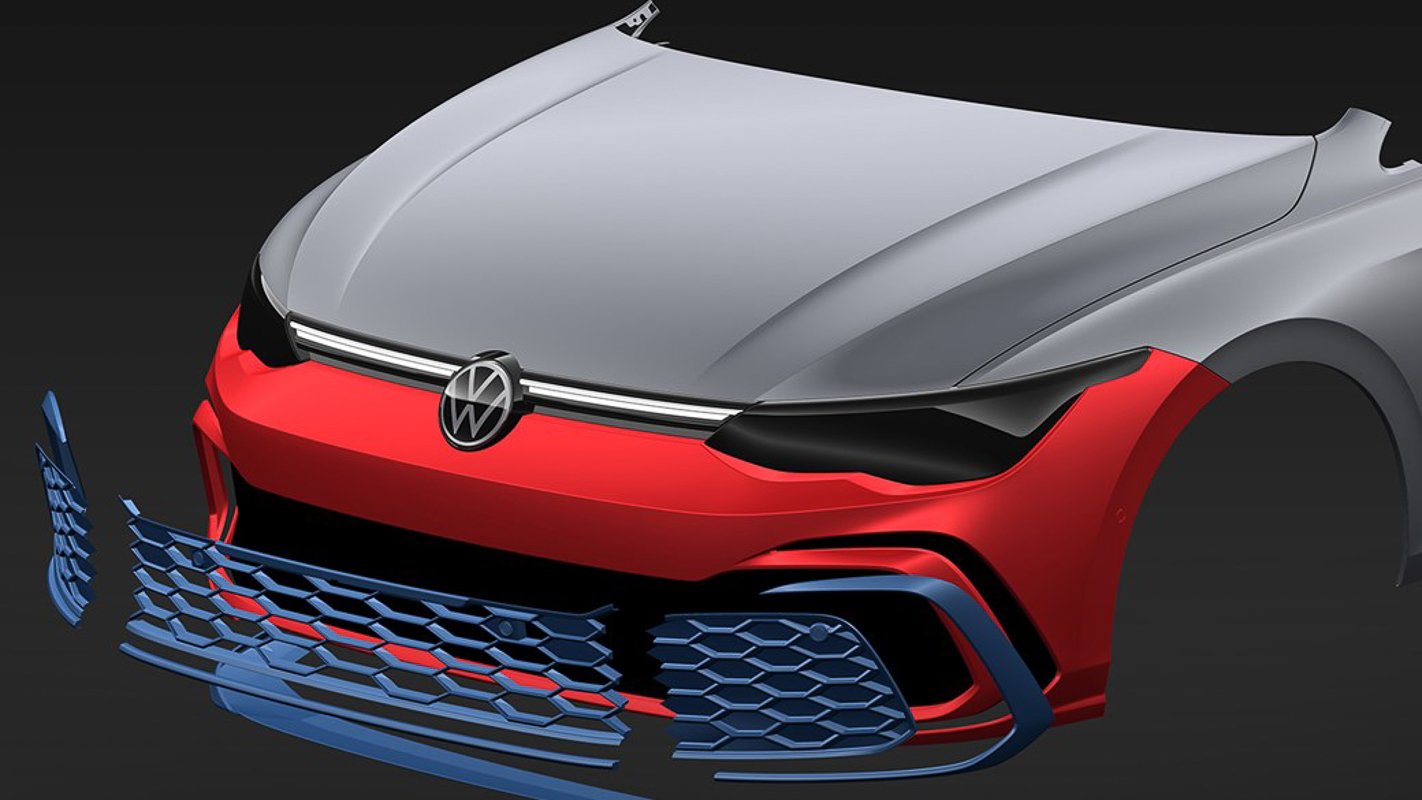

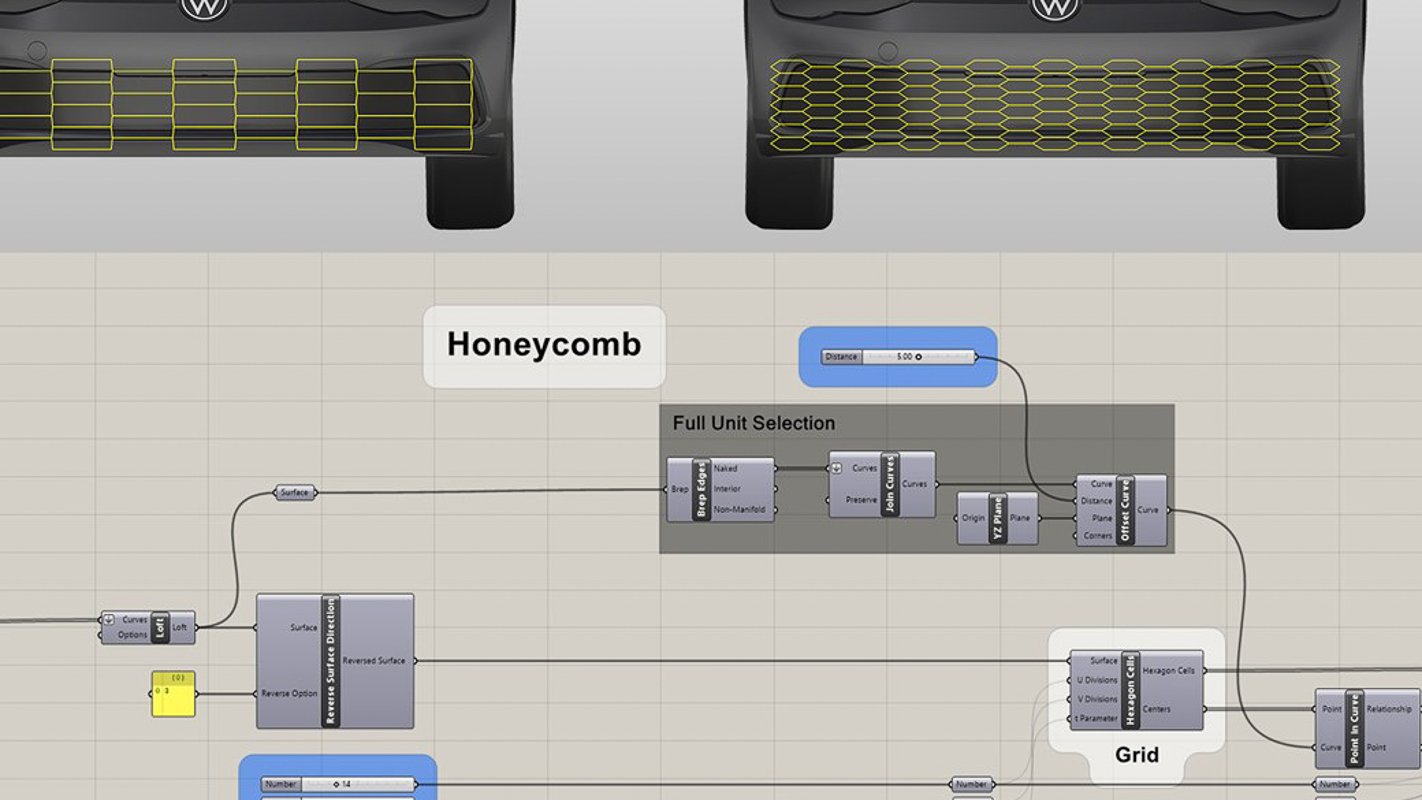

And because cars are getting more complicated in terms of design, these tools are almost necessary in order to finalise intricate details. Take the grille on the latest Golf GTI: that honeycomb layout is entirely computer generated. Designers input certain parameters to create the honeycomb and can then adjust the shape and size of the ‘holes’ infinitely, then graft it onto a 3D model of the front end. What would have taken months of minor tweaks to bring to life is done in seconds.

When a 3D model is created, there are also programs that can simulate certain times of day or night, and colleagues can even render said model in virtual reality for a slightly more tangible experience.

So, it’s all just one big happy family…

Not entirely. While Bischoff describes modern car styling as ‘team play’, design teams effectively compete with each other when it comes to pitching a design for a new model.

‘When we begin our design processes, we always have pitches that are worldwide. We do invite third party designers [there is, of course, Italdesign – a VW Group subsidiary], pitching against each other in a very challenging design contest, so to speak. from there we choose the best and then we go for three, then two and one.’ The final design is then decided by the VW Group board.

How much is VW relying on this, then?

The current systems the brand and Group are using have been utilised for the past five years after a slow rollout over a decade. ‘The generation six and seven Golfs were partly designed with these tools; the Mk8 is a truly digital design, as well as all the I.D. family members,’ says Bischoff.

And they’ll only become more essential to the design process. ‘Complexity [in car design] has grown but team size has also grown,’ says Bischoff, ‘in about 30 years the team size has tripled but the product portfolio has gone through the ceiling.’

This article was originally published at carmagazine.co.uk.