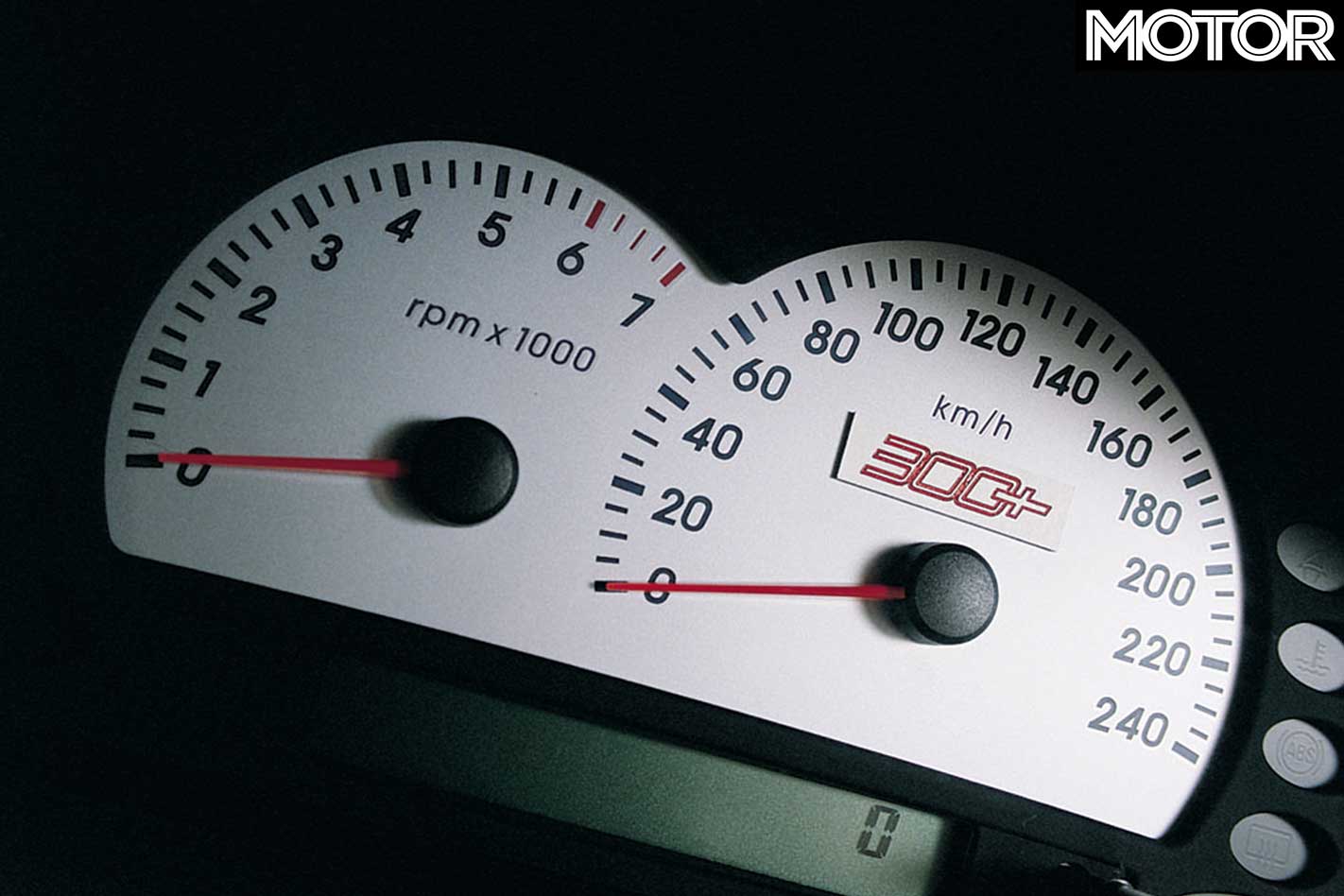

The bald figures read like a 911 Turbo spec sheet. Maximum power of around 310 kW. Torque in the vicinity of 500 Nm. Performance estimated at zero to 100 km/h in 4.6 seconds, and a standing quarter time of 12.6. In fact, the Porsche has proven it’s quicker than all that, but not by much.

This feature was originally published in MOTOR’s May 2001 issue

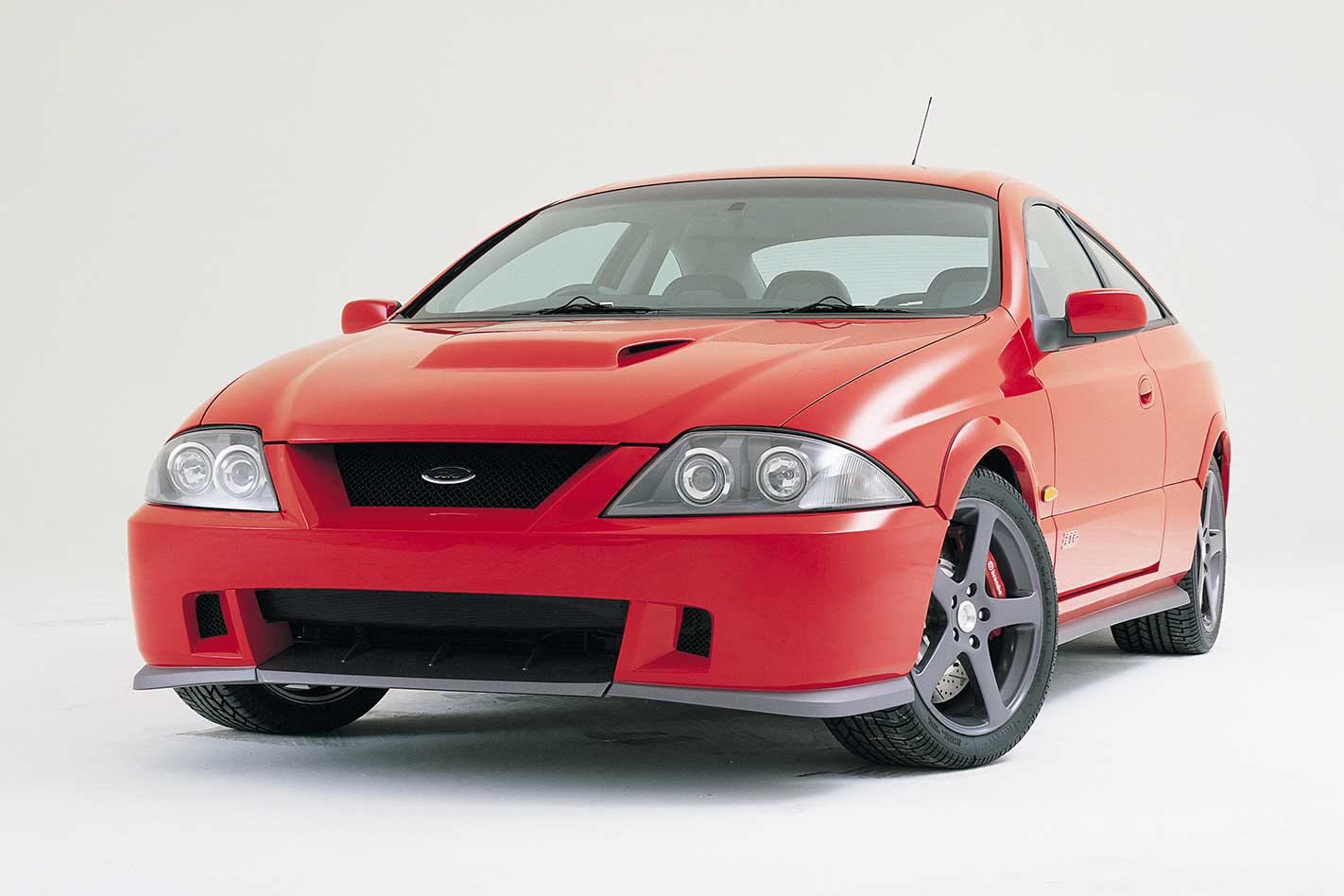

If you hadn’t guessed already, this is the car known as the 300+. It’s a two-door, supercharged V8 prototype that stands for plus power, plus performance and plus prestige for Ford, and as good a way to warn Holden the Blue Oval is still alive and kicking. Hard.

The big question for the moment revolves around the ‘ifs’, ‘arounds’ and ‘estimateds’, because the 300+ is still in the planning stage, even if history records that the first prototype was rushed together in only six weeks and wowed the crowds at the 2001 Melbourne motor show.

But Ford is so keen to make this happen you can almost smell the desire to reclaim the high ground of brute power vacated when the Phase IV XA Falcon project was killed off almost 30 years ago.

The politics, people and passion involved in getting even this far is a story in itself and detailed elsewhere here. The main thing is that the 300+ has got this far in these days of economic rationalism, cost cutting and, more specifically, Ford Australia’s less than flush financial situation.

You may not have heard of companies such as AEC or Venture, but they are among the driving forces behind the 300+. Welcome to the corporate street drags, circa Australia 2001.

DESIGN

The shape of the 300+ first emerged last winter when two brothers from Tenterfield, in NSW, quietly unveiled a hand-built, two-door AU Falcon coupe. Clayton and Troy Hillier’s Falcon two-door was the latest in a line of custom build jobs and never intended for serious production, but that was about to change.

Not long after the first pictures of the two-door started circulating, the Hilliers had a gent knocking on their door. His name was Danny Williams, manager of the Sprintex supercharger division of a company called Advanced Engine Components.

Williams said Sprintex had been developing a supercharged version of the Ford Mustang 4.6-litre quad-cam V8 and were trying to find the engine a home. How would they feel if their AU coupe was the car to do it?

The short story was that, yes, the Hilliers were keen to provide the basis for a two-door super-performance Falcon, and after Ford was contacted by AEC about the project, design duties were handballed to Millard Design. Millard was charged with building a prototype engineered to production standards, and was also given pretty much a clean sheet of paper to style the coupe as wild as you like.

According to Millard design director Paul Berenger, the brief entailed the mammoth task of transforming the Hillier car – “basically a pretty good cut and shut job” – into a production-ready prototype of a Ford performance flagship.

His team had from Christmas last year until the press day of the Melbourne motor show on March 1 to engineer and style the car, and the job was finished just four hours before Ford president Geoff Polites whipped the hanky off the 300+. So what was involved in determining the look of the car?

“The first phase was to immerse ourselves in the culture of two-door Fords,” says Berenger. “We had to envelop ourselves in the philosophy behind coupes like the Superbirds that were raced in the 1970s, but also went back to the Escort and Cortinas.”

From there, the process was two-fold: using computer-aided design (CAD) to strengthen the rear bulkhead and floor and increase the torsional stiffness lost by moving the B-pillar back about 200 mm and ‘puffing out’ the rear guards; and to produce the different shapes and surfaces required for the new sheet metal.

There was a distinct attempt at reducing the ‘crown’ effect, or the curvature of the car from the rear, and this was achieved by a flatter rear wing and the complex integrated high-mounted stop light, GPS antenna and phone aerial unit on the rear of the roof.

The front end, says Berenger, keeps the Falcon’s triangular themes but adds a lot more aggression. The bulging bonnet was needed to fit the taller overhead-cam engine with its supercharger installation, and then of course there’s the relatively simple grille and ground-scraping front airdam to go with the side skirts, rear bumper and other add-ons.

All this is wrapped around fat 18-inch alloy wheels, eight inches wide at the front and nine at the rear. The lower edges of the bodywork are painted grey, and poking out of the rear valance are a couple of turned aluminium exhaust tips.

“It’s a purposeful shape, mean and aggressive,” says Berenger. “I like to call it a junkyard dog – it’s got that sort of attitude.”

Inside, there’s a dashboard based on the high-series (Fairmont) design, and the seats have been recontoured for more lateral support. The AU Ute donated its folding front seat mechanism that gives access to a rear pew with a surprising amount of leg and headroom, and it’s here that the Falcon 300+ is separated from most other coupes. Not only does it look good, there’s a useful amount of interior and boot space as well.

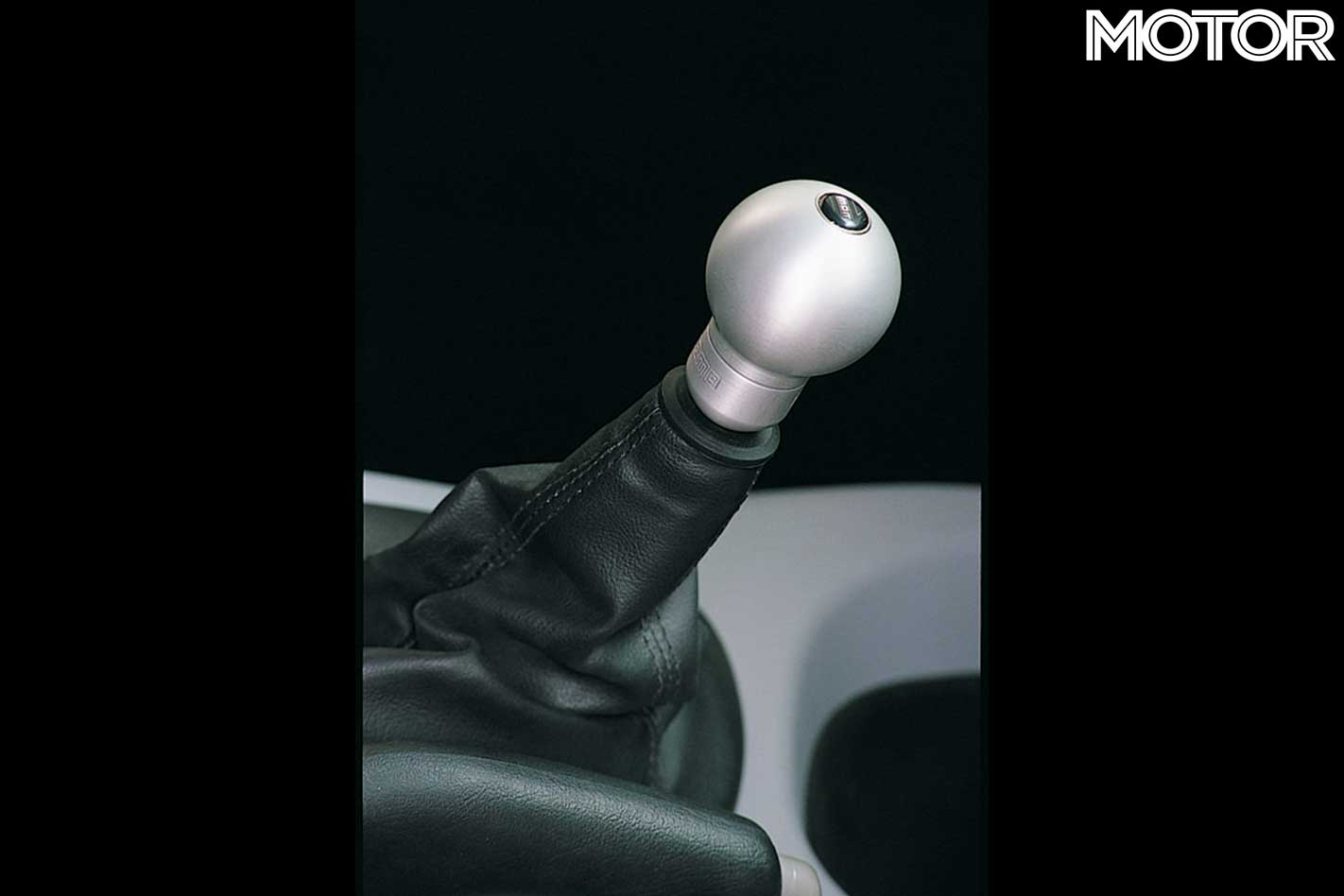

Other interior touches include plenty of alloy trim for the gearknob, pedals and kicker plates, and more colour as well, but we’ve all seen plenty of fancy stuff fitted to show cars that comes out looking a lot less exciting in production. If the 300+ goes ahead, how much of the show car will make it onto the road?

“Every part you see has been designed and engineered for production,” says Berenger. “So, given the premium position it’s been placed at, I can’t think of a reason why customers won’t get the lot.”

ENGINE & TRANSMISSION

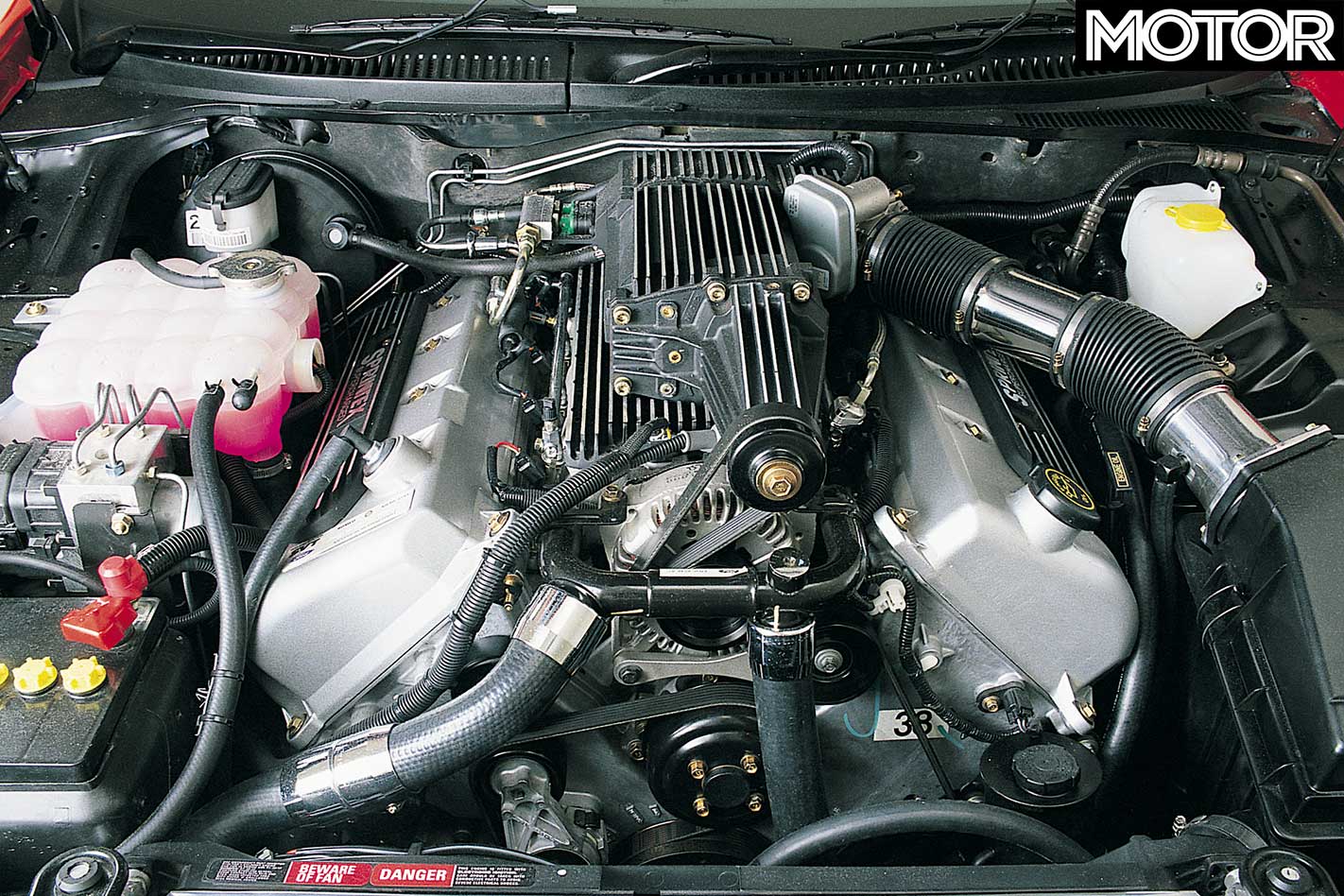

While the 300+ project might be a combined effort involving Millard and Ford, the baby really belongs to AEC, and it is them we can thank for the boot-in-face outputs being credited to the 4.6-litre Mustang V8.

According to Sprintex’s Danny Williams, the 4.6 is where the whole story started, thanks to Ford Australia asking Sprintex to quote on a supercharger job for the engine, which at the time was being considered as a replacement for the Windsor 5.0-litre.

It’s history now that Ford has decided to stick with the Windsor until 2002, but the project left Williams with costing for the blown 4.6, and the Hilliers had a car that could use it.

Amazingly enough, the guts of the engine remain fairly standard. In fact, after fitting the supercharger the task was not how to make the power output high enough, but how to keep it in check. Think about it: the Cobra engine puts out 240 kW, and taking it up to 310 kW is an entirely reasonable 30 per cent increase.

“The aim was to produce Australia’s first 12-second quarter mile car,” says Williams. “Our drag simulator said 310 kW was enough at this vehicle’s weight.”

The supercharger is the latest Sprintex 3-series 355 twin-screw unit, and hasn’t been used on a road car before. It has a couple of neat features, not least of which is that it is cheaper and easier to manufacture and has a more effective rotor profile than before.

AEC has also ditched the Mustang’s (and Falcon’s) normal throttle cable for a fly-by-wire unit, and the supercharger’s idle bypass is also electronic.

That means that on a partially opened throttle when no boost is needed, the supercharger is effectively shut down, resulting in less energy loss because it is no longer being driven. Better still, electronic (rather than the usual vacuum-assisted) throttle bypass allows for minute adjustment to boost control, which effectively can take the place of a knock sensor.

This engine runs the standard 9.85:1 compression ratio, so backing off the boost before detonation occurs is essential.

Maximum boost is a low five pounds, resulting in the desired 310 kW at 6200 rpm, and a massive 575Nm of torque at 3750 rpm. Creating that bottom-end grunt was one of the major aims with the engine, says Williams, because although the Cobra engine will rev to the ends of the earth the only complaint he’s heard was a relative dearth of pull from very low revs.

That sort of output required replacing virtually everything between flywheel and tarmac, starting with a six-speed TTC Tremec T56 manual gearbox – the same unit used by the Holden Commodore V8. The idea of a sequential shift was toyed with, but won’t make it to production, initially at least.

The 11-inch SVO clutch comes straight from the Mustang Cobra and is man enough for the job, but the Falcon’s aluminium driveshaft was ditched in favour of something stronger, and one which can cope with speeds over 180 km/h. The Sprintex-designed ECU has no speed limiter, according to Williams.

In line with Ford’s insistence that the 300+ showcase the best available Australian technology, AEC has specified the independent rear suspension. And although the Ford 8.75-inch diff was fine, the axles needed strengthening. After a bit of head scratching at AEC, Harrop Engineering came up with an IRS compliant, nine-inch diff complete with finer splines, stronger axles and a neat magnesium housing. Expensive but necessary, and beautifully engineered.

Although a 300+ test mule is running around Perth – don’t get too excited, it’s a four-door – performance figures haven’t been officially measured. As mentioned at the start of this yarn, they’re going to be sensational in what is a relatively lightweight 1660 kg coupe. We’ll get back to you on that, hopefully later this year.

SUSPENSION & BRAKES

Perhaps the area where the 300+ really shows itself as a prototype is in the suspension. Don’t get us wrong: all the hardware is there and Ford Motorsport has even developed initial settings, it’s just they had no time to drive the car before it went on show.

The basic package is pure Falcon, albeit with Koni dampers, revamped bushes and sway bars, and appropriately shorter and stiffer springs.

Howard Marsden’s motorsport department is responsible for tuning the lot and adding hardware if necessary, and don’t be surprised if someone like Craig Lowndes is used to make it every bit as sweet as the TE50 in the handling department, albeit beefed up to accept higher velocities.

Speaking of which, the 300+ should have adequate stopping power thanks to a monster Brembo brake package. There’s 365 mm slotted and drilled DBA discs and four-piston calipers at the front and 330 mm slotted and drilled DBA discs with twin-piston calipers out back.

Tyres were Pirelli P-Zeros on the prototype but are likely to be all-new P-Zero Rossos once production begins. It is seriously sticky rubber and plenty wide enough, with 275/35 ZR18s at the rear and 245/40 ZR18s at the front.

As with performance, the handling story of the 300+ might sound brief, but is best described once the car has been driven. You’ll no doubt be hearing plenty more about this car before it is launched, and if we were betting guys it’s got to be two-to-one on that Ford will have difficulty backing out now. Us? We can’t wait to get behind that wheel to find out.

Method in the madness

The Falcon 300+ coupe represents quite a different approach to how Ford normally builds cars. It was conceived and has been engineered largely outside Ford’s normal systems, has happened very quickly, and it will be a limited-edition and very expensive run. It also might not yet happen at all, even though Ford has worn its corporate heart on its sleeve by openly displaying the prototype. So what gives?

“It’s probably no secret we’ve been doing it tough the last couple of years,” says Rick Nayler from Ford’s Special Vehicle Operations division. “Personally, I saw this project as an opportunity to show the public we are quite capable of being an exciting company.”

As business development manager of SVO, Nayler’s job is to lead the Ford Tickford Experience (FTE) and in some ways act as a bridge between Ford and Tickford. It was he and Howard Marsden – Ford’s motorsport manager – who listened hardest to AEC’s proposal, and who helped decide whether the 300+ deserved full factory backing.

Ford President Geoff Polites was a strong supporter on the proviso the car was properly engineered, so Millard Design was brought onto the scene. Millard was able to offer much more than just its state-of-the-art styling studio.

The company is owned by Venture Industries, a multinational specialising in automotive parts and, particularly, plastics. It operates the plastics plant situated within a stone’s throw of Ford’s head office in Campbellfield and produces a hefty swag of Falcon parts.

No beginner in the field, Venture is well placed to not only design and manufacture add-on plastic body parts but, more critically, to produce the low-volume tooling necessary for the unique metal body panels.

But the player with the most involvement is Advanced Engine Components, owner of the Perth-based Sprintex supercharger company that convinced Ford the 300+ should be a goer. More than just an engine supplier, through manager Danny Williams AEC convinced the Hilliers their coupe could reach greater heights and has bankrolled the project to the tune of millions of dollars.

According to Nayler, the 300+ now enters its most critical phase. He said the aim of its Melbourne motor show appearance was to gauge reaction from the public and dealers, and it seems to have worked. Apart from the media going ga-ga, he’s receiving calls from dealers telling him buyers want to know when they can put down a deposit, and for how much.

A decision on the future of the 300+ will be made within weeks. The aim would be to start production in 2001 but before that the business case must be iron-clad. Then it’s a case of finding space for a low-volume plant to bolt the thing together.

There’s also the matter of a name. Nayler won’t be drawn on whether 300+ will stick, saying no decision has been made. Funnily enough, there’s little for Ford to fall back on historically because, unlike the Monaro, the Superbird tag of the 1970s was never in popular usage. Performance Falcons have always been GTs in all their phases, so perhaps that’s a better way to go.

FAST FACTS Ford 300+

BODY: 2-door coupe DRIVE: rear-wheel ENGINE: 4.6-litre quad-cam 32V V8, supercharged BORE/STROKE: 90.2 mm x 90.0 mm COMPRESSION RATIO: 9.85:1 POWER: 310 kW at 6200 rpm TORQUE: 575 Nm at 3750 rpm WEIGHT: 1660 kg POWER-TO-WEIGHT: 187kW/tonne TRANSMISSION: six-speed manual SUSPENSION: double wishbones, coil springs, anti-roll bar (f); independent by double wishbones, coil springs, anti-roll bar (r) L/W/H: 4910 / 1892 / 1400 mm WHEELBASE: 2793 mm TRACKS: 1566 mm (f); 1547 mm (r) BRAKES: 365 mm slotted and drilled discs, four-piston calipers (f); 330 mm slotted and drilled discs, two-piston calipers (r), ABS WHEELS: 18 x 8.0-inch (f); 18 x 9.0-inch (r), alloy TYRES: Pirelli P-Zero, 245/40 ZR18 (f); 275/35 ZR18 (r) FUEL: 68 litres, PULP PRICE: $100,000 (approx)