- Tesla to produce batteries in-house

- New battery design will boost range by 16 percent

- Cobalt to be eliminated from battery production

Speaking at the highly-anticipated Battery Day presentation at the Tesla Gigafactory in Freemont, California, Tesla co-founder Elon Musk said the company plans to significantly increase battery production to make its electric vehicles more affordable.

“About three years from now, we’re confident we can make a very compelling (US) $25,000 electric vehicle that’s also fully autonomous,” he told socially distanced Tesla shareholders and owners sitting in their cars drive-in style at the event, which was also streamed live around the world on YouTube.

He did not say if an affordable new Tesla model was actually under development, though, or even if it had a name.

Musk had previously predicted Tesla would reduce the costs of production of its vehicles to produce a US$25,000 EV back in 2018, also giving that a three-year deadline, but this time he says it will be possible through the company’s ambitious plan to produce more batteries more efficiently. If the plan comes off, the company will make the cheapest Tesla to date… and it won’t hurt the Tesla share price, either.

This includes producing its own newly-designed lithium-ion batteries from the ground up and increasing annual total battery output from 100 gigawatt-hours (GWh) to 3.0 terawatt-hours (TWh) by 2030 without having to build more factories – a GW is a million watts, a TW is one million, million watts.

He said producing cheaper batteries in bigger numbers was the best way to reduce the cost/kWh curve to make EVs more affordable, adding it was no point making cars that people desired if they could not afford them.

“It’s super critical we make cars that people can afford,” he said.

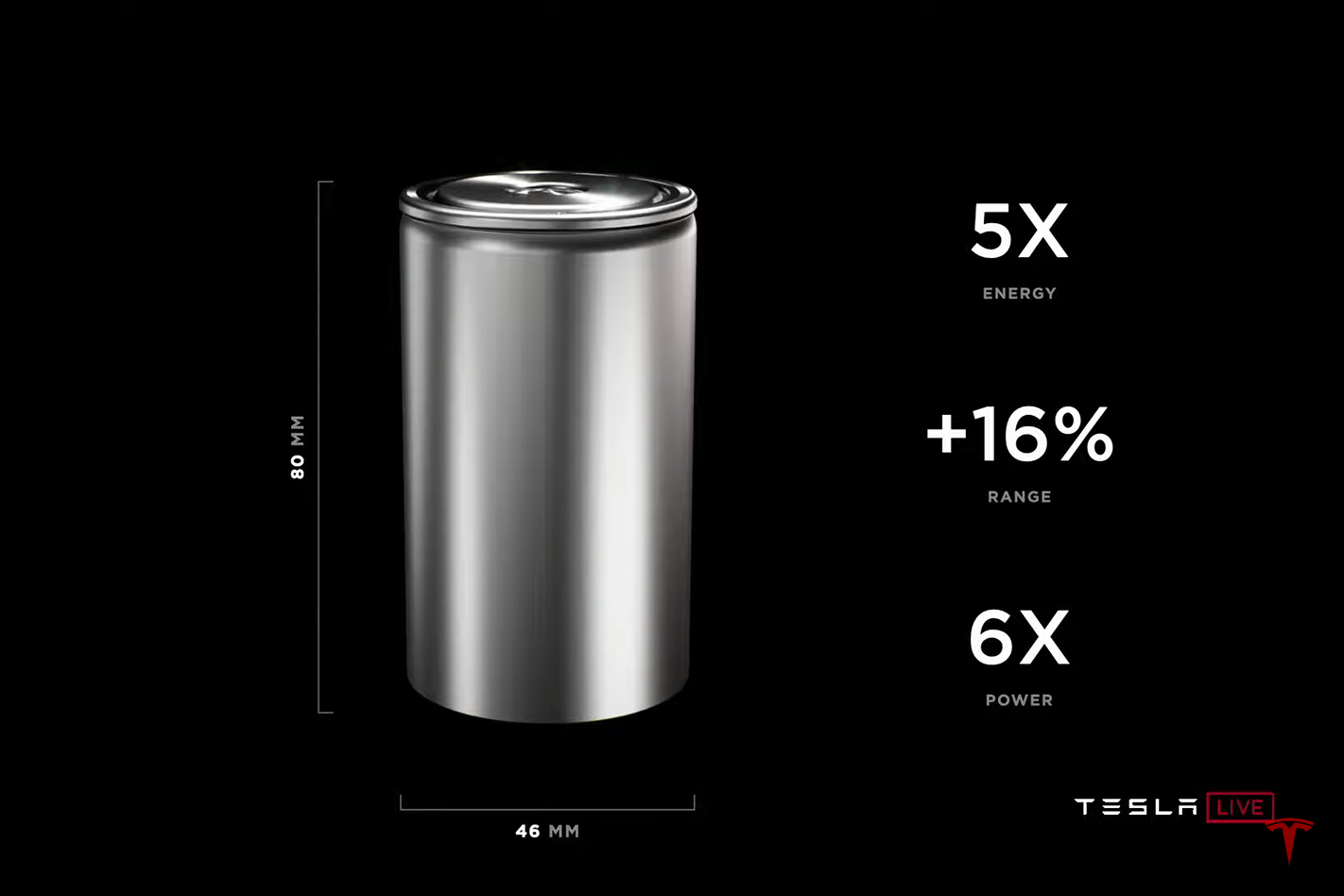

New battery design

One of the ways Tesla is working to bring costs down is by producing its own redesigned ‘tabless’ lithium-ion batteries from the ground up.

The new batteries will be bigger but more thermal-efficient by doing away with the tab or strip that connects the cells and slows the flow of electrons.

It’s anticipated the tabless batteries will produce six times more power and increase range by 16 percent – this would give a Tesla Model S a range of around 750km.

Tesla is also working on a new dry-cell that eliminates the need to apply a wet film on the electrode, which is one of the most energy-intensive stages of the battery-making process. However, the solution, which involves applying a dry Nickel film is not yet suitable for large scale production.

It is also looking to eliminate the use of cobalt in the battery cathodes in favour of nickel. As well as making batteries cheaper, this will do away with the cobalt mining process that is plagued by human rights issues such as child labour and hazardous working conditions.

The battery and vehicle manufacturing process is also being streamlined by reducing the number of stages and components required to speed up production.

Musk said this would allow one factory to produce what five could currently do.

“Tesla is aiming to be the best at manufacturing of any company on earth,” he said.

“Every car company will have long-range electric cars, every company will have autonomy but not every company will be great at manufacturing.

“Tesla will be absolutely head and shoulders above everybody in manufacturing. That is our goal.”