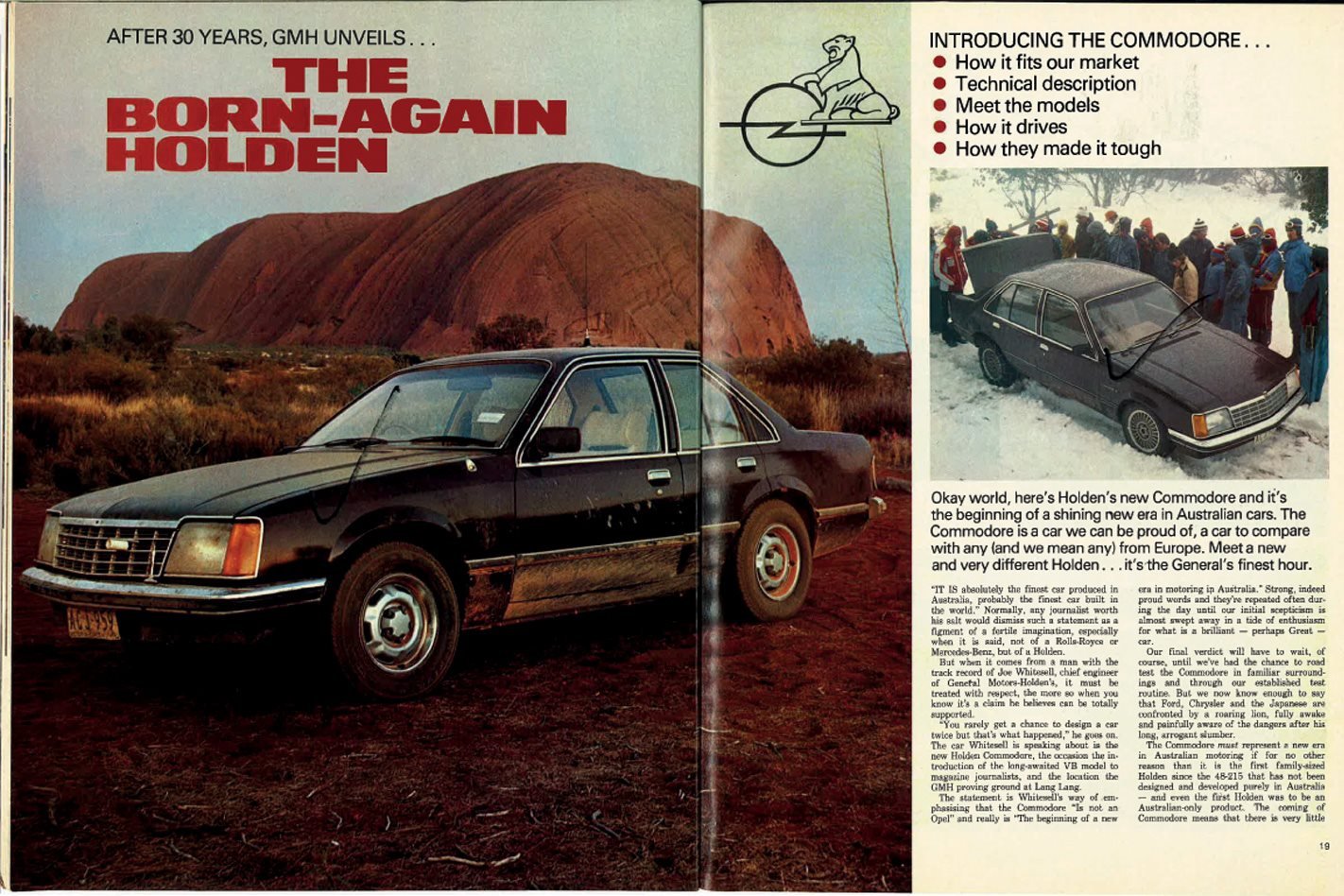

“IT IS absolutely the finest car produced in Australia, probably the finest car built in the world.” Normally, any journalist worth his salt would dismiss such a statement as a figment of a fertile imagination, especially when it is said, not of a Rolls-Royce or Mercedes-Benz, but of a Holden.

But when it comes from a man with the track record of Joe Whitesell, chief engineer of General Motors-Holden’s, it must be treated with respect, the more so when you know it’s a claim he believes can be totally supported.

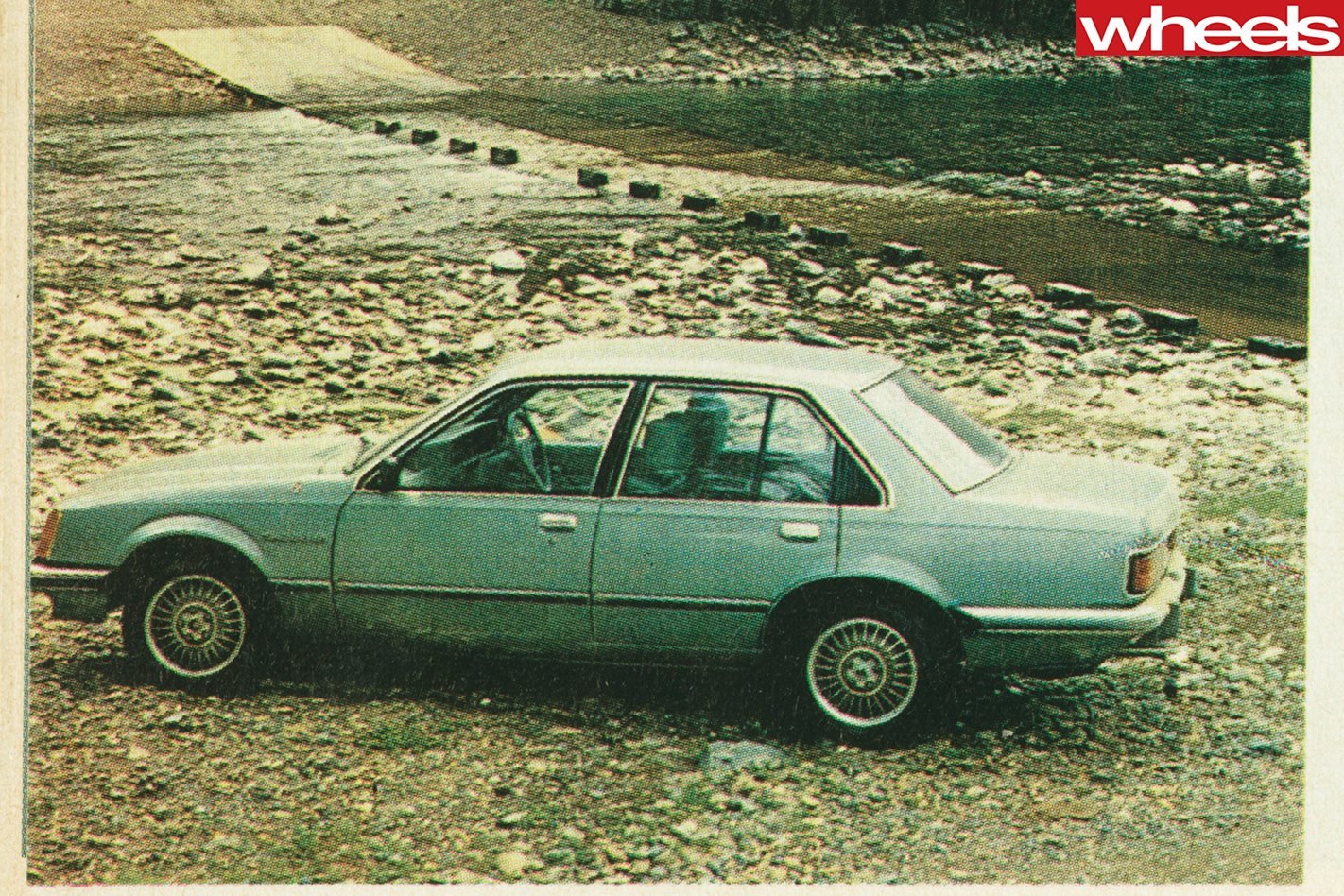

The statement is Whitesell’s way of emphasising that the Commodore “is not an Opel” and really is “The beginning of a new era in motoring in Australia.” Strong, indeed proud words and they’re repeated often during the day until our initial scepticism is almost swept away in a tide of enthusiasm for what is a brilliant – perhaps great – car.

Our final verdict will have to wait, of course, until we’ve had the chance to road test the Commodore in familiar surroundings and through our established test routine. But we now know enough to say that Ford, Chrysler, and the Japanese are confronted by a roaring lion, fully awake and painfully aware of the dangers after his long, arrogant slumber.

The Commodore must represent a new era in Australian motoring if for no other reason than it is the first family-sized Holden since the 48-215 that has not been designed and developed purely in Australia – and even the first Holden was to be an Australian-only product. The coming of Commodore means that there is very little chance of a wholly-Australian car ever happening again, at least from GMH and probably from the entirely local industry, after the XD Falcon.

The Chapman/Whitesell team, which has so dramatically changed the philosophy and therefore the cars of GMH, was largely responsible (along with stylist Hank Haga) for the Opel Rekord. But the need to make the Commodore at least 85 percent local (local content is at 85-88 percent now and will rise to 90-94 percent early next year) allowed The General much latitude in tooling so any areas they were unhappy about could be modified or even completely changed to produce a better car.

Having driven the top-line Opel Senator, which is based on the Rekord but has a fuel injected, three-litre six-cylinder engine and independent rear suspension, I can only confirm the view that GMH has indeed built a superior car.

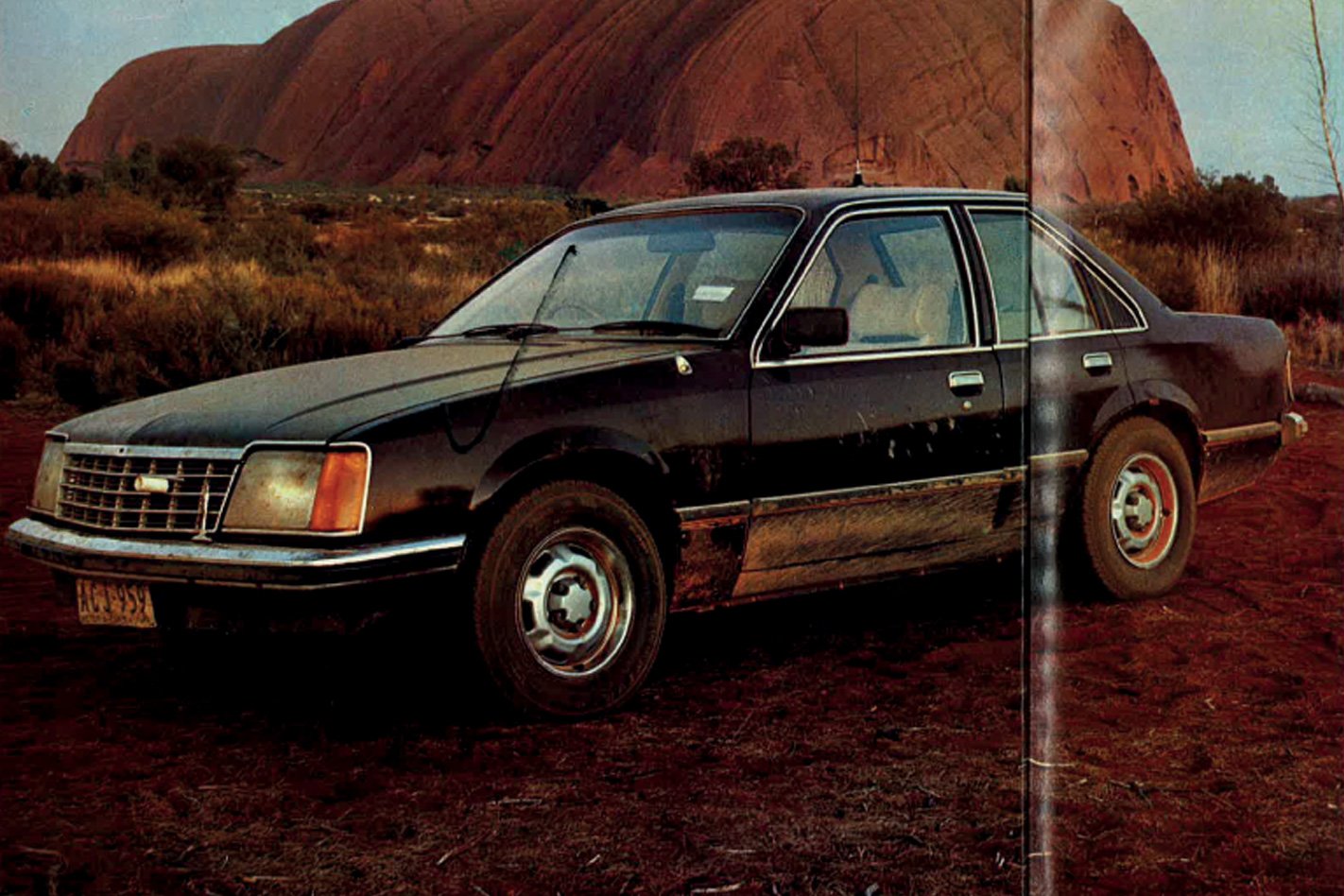

The General believes the Commodore will be the top selling Holden in 1979 – and the top selling car in Australia – although it is only available as a four-door sedan, in three forms, with a station wagon to follow in March/April next year. In exterior size – as we’ve pointed out before – it fits neatly between the Torana and Kingswood, and ultimately it will replace either one or, perhaps even, both. GMH is honest enough to admit it doesn’t know.

Development work on the V-car program began in Germany in 1971 and even in the preliminary stages it was designed to accommodate engines from all GM’s overseas operations including the Holden eights and sixes. But it was not until early in 1975 that GMH decided the V-car had the potential to become a local best seller. After research clinics in November 1975, July 1977, and August this year it now believes it has a car which will meet the needs of the majority of Australian motorists in the 1980s.

GMH explains the Commodore’s space efficiency by comparing its shadow area – the rectangle formed by the car – with the Torana and Kingswood. The Commodore is five percent bigger than the Torana and 14 percent smaller than the Kingswood, and yet it has 96 percent of the bigger car’s interior room. The only dimension where it suffers by comparison with the Kingswood is in shoulder width where it is about 40 mm narrower but still wide enough for it to be regarded as a full five seater. Also significant is the fact that the Commodore has 14 percent more glass area than the Torana and 4.3 percent more than the Kingswood. Proof that it has an extremely low waist line and large rear window.

But space efficient cars are not necessarily strong cars and GMH’s engineers had to ensure that the traditional Holden qualities of durability and reliability were retained. The Commodore is 130 kg lighter than a comparable Kingswood and only 38 kg heavier than a similar Torana.

The Rekord was designed using the latest “finite element analysis” computer technique, which stress analyses every area of the car’s body to maximise strength and durability while minimising weight. VW used the same process in designing the Golf.

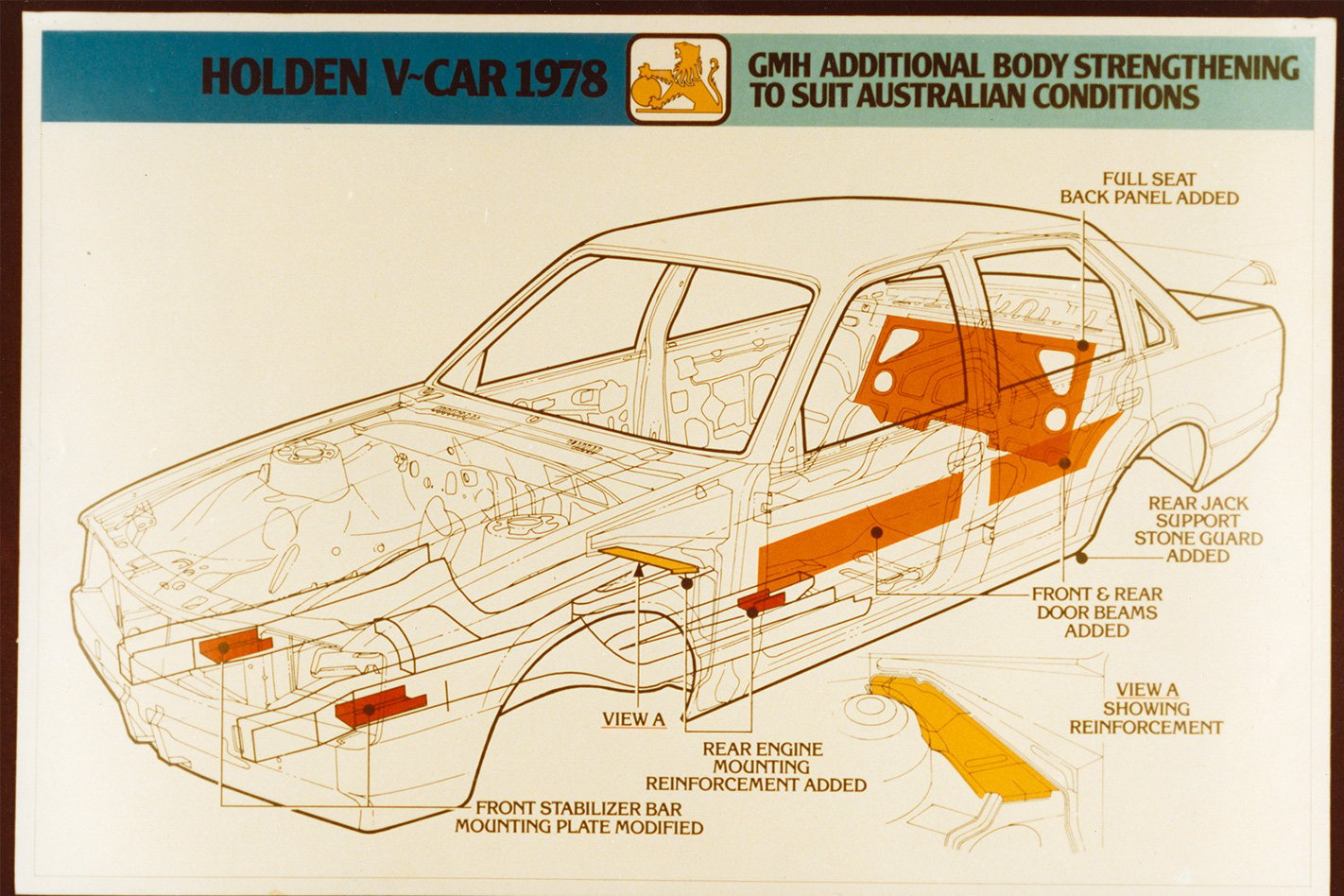

For a while The General considered building two cars – one capable of withstanding all that tough Australian roads could throw at a car and the other suited for normal commuter type work. Sales volumes ensured that only one car be built … we got the tough version. From load spectrum data GMIH has collected on a wide variety of local roads it believes cars in Australia have to absorb three to four times as much punishment as experienced in Europe.

Over 270,000 kilometres of road and proving ground tests in all states of Australia exposed other problems which meant fitting a closed box section from the MacPherson strut front suspension tower to the firewall, a modification to the front stabiliser bar mounting plate, reinforcement for the rear engine mounting, the addition of a full back seat panel, a stone guard support for the rear jacking point, and front and rear door beams.

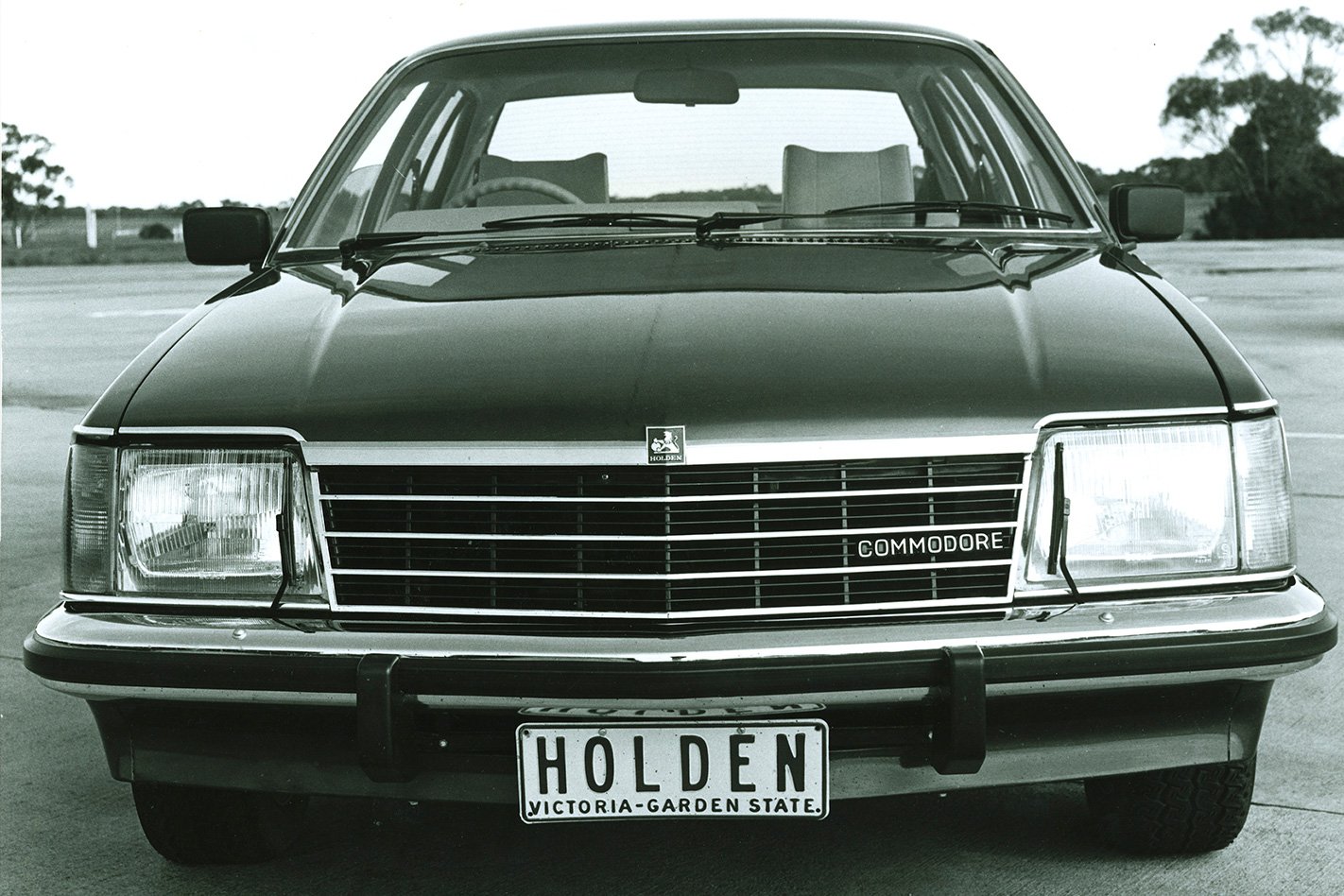

Now GMH believes it has a car which combines the best of its European design talents with the strength expected from a Holden. It is a formidable combination. Opel used Pininfarina’s wind tunnel to style the car. According to local styling chief Leo Pruneau “you let the tunnel tell you what the car will look like”. Which is probably the perfect answer to anyone who questions why so many of the new designs coming out of Europe tend to follow a look-alike path with the same sloping nose treatment.

More importantly, the wind tunnel allowed Opel’s engineers to ensure straight line stability is good, that wind noise is kept to a minimum and that any lift forces are reduced. Our brief drive did nothing to indicate the engineers and stylists got their homework wrong.

In addition to producing a body which looks attractive and is strong, GMH went to a great deal of trouble to ensure it can also combat the dreaded corrosion. The Commodore uses a single sided zinc pre-coated steel and all vital areas also get zinc rich pruners or tectyl coating. In fact about one kg of zinc is used on every car. There is also a corrosion resistant prime dip and a wax spray. The General’s objective is for there to be no body panel perforations before 10 years in 95 percent of cars operated in south-east Queensland.

In search of a more comfortable ride, Opel’s engineers adopted a MacPherson strut front suspension. While understanding the advantages of such a set-up, GMH must have been concerned about the durability of the struts in local conditions, especially in view of the poor durability displayed by struts in some British and European cars.

Instead of the cartridge type struts used on the Opel, GMH has developed, with local suppliers Monroe-Wylie and Armstrong, a “wet” strut design. The outer structural tube is filled with liquid which dissipates heat through its large surface and reduces the internal temperature, thus minimising fade.

GMH claims the strut allows precise damping control due to its direct attachment to the wheel and that castor and camber can be easily adjusted one degree plus or minus at the top of the struts.

The front spring rates – the coils are linear rate and not progressive – are almost 50 percent higher than those on the Kingswood and this has been largely responsible for the significant increase in ride comfort. A front anti-roll bar of 23 mm diameter is linked to the lower control arms and passes through rubber bushings mounted on the front sub-frame.

progressive rate rear coils provide 40 mm more suspension travel than the Kingswood – again for improved ride comfort – but still without impairing the precise handling or making for a reduction in roadholding.

The system also makes for a very quiet ride. All cars get a rear anti-roll bar that is mounted directly to the body. The rear dampers are mounted vertically and close to the wheel. There’s no talk of the German independent system being used locally. GMH claims it’s not needed.

Steering was another area in which Holden’s second go at the V-car design meant a genuine improvement over the Opel.

All cars have steel belted radial ply tyres on six inch rims as standard, the six-cylinder models get CR78 S14 tyres, the V8s CR70 H14s, and the new 60 aspect ratio Uniroyal and Olympic BR60 H15 are standard on the SL/E and optional on other models with GMH’s own alloy wheel.

The local engineers have also developed two new braking systems which give a good front and rear balance and restrict lock-up to the point of virtual elimination. They also change the old over-servoed feel of previous Holden brakes to a much firmer pedal with more progressive feel. The base system used on the Commodore and Commodore SL is a disc/drum set-up, the SL/E gets four wheel discs which are optional on the other models. Both share the same vented discs at the front with new lightweight sliding head, front calipers (locally developed with Girlock), and a lightweight master cylinder with in-built proportioning valve. The rear drum brakes have a new GMH manufactured leading/trailing system which maintains good balance and incorporates a self-adjusting mechanism. The rear discs have a similar sheet metal caliper design (it saves five kg over a conventional rear caliper) to those at the front but it incorporates a mechanical duo-servo drum brake for the hand brake.

GMH says 65 percent of the parts in the Commodore are Holden designed and developed, the biggest single contributor to this must be the local six and eight.

Three on the tree is dead. Even the base Commodore has a four-speed manual gearbox and the SL has the Trimatic automatic with console shift as standard. Four-speed manual and Turbo-Hydramatic transmissions are optional on selected models. The four-speed is the Philippines box and is a little notchy in its change action. The clutch is cable operated but on the V8 is sufficiently heavy in its action as to be out of character with the rest of the car.

The propeller shaft is a two piece design with rubber insulated centre bearing and a constant velocity centre joint. GMH’s new found emphasis on noise and vibration has meant the tail shaft has been tuned to match the smoothness of the rest of the car.

With the help of a Fourier analysis computer and a very thorough examination of all relevant areas the engineers have built an extremely quiet car. Noise and vibration has been reduced at their source, natural resonant frequencies of all major mechanical items have been moved outside the driving range and dampening has been used where it was not possible to isolate its natural frequency. This has meant that door seals, the shape of the drip mouldings, the compound of the rubber bushes and even such items as the brake lines, wiring harness, seat springs, and door handles have been designed to eliminate all possible disturbances. The result is a super smooth, quiet car.

The standard ventilation system has a four-speed fan and is capable of changing the air inside the car two and a half times every minute. There are four dashboard vents and two additional vents at foot level; it seems to work very well.

The air-conditioning system is controlled by just one turn knob and uses the same vents as the standard ventilation. It can direct warm air to the feet and cool air at the upper levels. The interior is modern without being revolutionary. The glove box is a bin type and there is a small recessed tray atop of the dashboard in front of the passenger. The instruments and heater/air-conditioner use printed circuits.

The General believes 50 percent of Commodores sold will be the base car, 30 percent SLs, and the rest SL/Es. How Australians will take to a smaller, more efficient and very un-Holden Holden remains to be seen, but we can only agree with an engineering friend who has been involved with the car at the component level, who says “if the Commodore doesn’t succeed then we all deserve to be driving Datsun 200Bs”.

More strong words, but the claims have been made and in future issues we will be striving to discover their truth or otherwise. Somehow we don’t think we’ll be disappointed.