I PURCHASED my first winch back in 1984 from a buddy’s dad: a well-used Warn upright with a cable-operated brake. I didn’t know anything about the winch or how to use it, but I knew I needed something to pull me out of future jams and Warn had the Xerox reputation in the industry.

Little did I know at the time that I was entering a paragraph in what would become a 70-year chronical of high-quality off-road products. Recently, I took the opportunity to visit Warn’s headquarters in Clackamas, Oregon, tour the production plant, and dig into the company’s rich history.

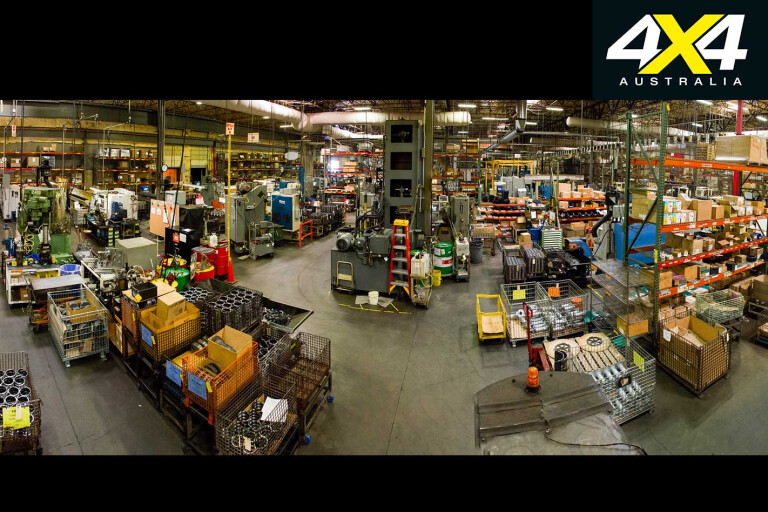

I met with systems technician Chad Schroll for a tour of their 200,000ft² facility. From the catwalk of a 20-foot-tall gear-cutting broach, overlooking CNC mills and plasma tables, he shared the company’s humble beginnings. While many only associate the Warn moniker to its line of winches, the company’s roots lay slightly aft of the fairlead – capping the front axle to be exact.

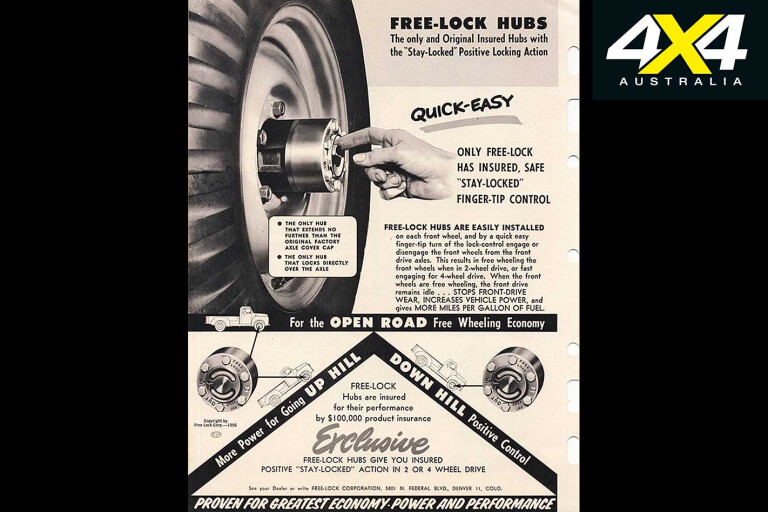

After WWII, surplus Willys flat fender Jeeps, which could be purchased for a few hundred dollars, flooded the civilian markets. Arthur Warn, who had opened a Willys dealership with his wife Sadie in Southpark, Washington, in the 1930s, realised the need for a way to disengage the front axle to allow for on-pavement use. He took it upon himself to design a new hub to allow for “free-wheeling” in two-wheel drive.

Early sales were generated by going door-to-door demonstrating the new product, but upon his wife’s suggestion Arthur invested in an ad in Popular Mechanics. It not only provided national exposure, but was the catalyst for future global expansion.

After a few years perfecting the application, Warn approached the automotive industry and his hub became a factory option for several brands, eventually becoming the OE fitment for International Harvester, Kaiser Jeep, Ford and Chevrolet.

There were various iterations over the coming years – the Lock-O-Matic selectable and the Automatic, which relied on internal friction clutches to apply torque to the wheels – but the headline news landed in 1959 when Warn partnered with Bellevue Manufacturing to create the first vehicle-based electric winch.

The M6000, affectionately referred to as the Bellevue, eliminated the issues associated with power takeoff (PTO) and hydraulic options. Namely, the engine did not need to be running to self-recover the vehicle.

The Bellevue was an instant hit with the growing off-road enthusiast market, and in 1974 it was redesigned as the venerable M8274. The 8274 penned the opening chapter for an epoch of growth for the company. The “M” indicates model, “8” is the capacity (8000 pounds), “2” denotes two-way operation (power-in and free spooling), and “74” was the first year of production.

During the ’70s and ’80s Warn expanded its line of winches, developing its first three-stage planetary gear model, which now ranges from minuscule UTV options to massive 30,000-pound industrial models. In the past decades Warn winches have been utilised by off-roaders, the towing industry, and military forces around the globe. At one time it even developed a limited-slip differential.

As the company gained financial clout it introduced bumpers, body armour, auxiliary lights, utility winches and, as of late, recovery gear – and lest we forget the beloved Warn overdrive. Born in 1961, this miracle gearbox allowed our painfully slow Jeeps to keep up with increasing highway speed limits, while improving fuel economy and range. To this day it can be found in thousands of vintage Jeeps the world over – I run one in my 1952 Willys CJ3A and I love it!

What the future holds

DURING the past decades the shift to outsourcing production overseas has put considerable pressure on companies to follow suit.

When I asked Chad about Warn’s stance on the subject he said: “Much of the foundry work is still done here in the USA, and we cut almost all of our gears and do most of the machining and assembly here in Oregon. It is a delicate balance. We do have some parts made overseas, but we have full oversight of every step of the process, as well as full control of QC. The reality is, with electric motors for example, we can’t get them in the States anymore.”

As I walked through the building I witnessed Warn’s various product lines being transformed from neatly organised carts of machined parts and sheets of plate steel, into freshly powder-coated winches, hubs, bumpers and accessories ready for a box and a bow tie. It is an impressive operation.

Family control ceased in 2000 when the company was acquired by an equities firm, but Warn has been able to retain its autonomy and remains a driving force in the sector. Chad informed me that they have more than 350 boots-on-the-ground staff in the US. In a world where manufacturing has almost entirely been shifted to Asia, these were good words to hear.

During my visit I talked with dozens of machinists, welders and technicians and was impressed to find that many have been with Warn for more than 20 years, and some more than 30. Long-term employees are always a sign of a healthy, well-managed company.

As a leading innovator in the genre, Warn holds dozens of patents and has been the recipient of numerous industry accolades including 20 SEMA Best New Product and Global Media Awards. Warn isn’t the only name in town when it comes to quality recovery gear, but I’ve run Warn winches (including that old used Bellevue) on my four-wheel drives for the past 30 years and always felt confident that they would answer the call to duty – which they have.

As the company celebrates its 70th anniversary, it’s exciting to witness its continued success and it’s good to know that Warn’s employees will still be churning out some of the best products in the industry, right here in the good old USA. Arthur Warn would be proud!

Warn winches and recovery gear are distributed in Australia by both Ateco and ARB 4x4.

COMMENTS